- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ม.ค. . 24, 2025 03:15

Back to list

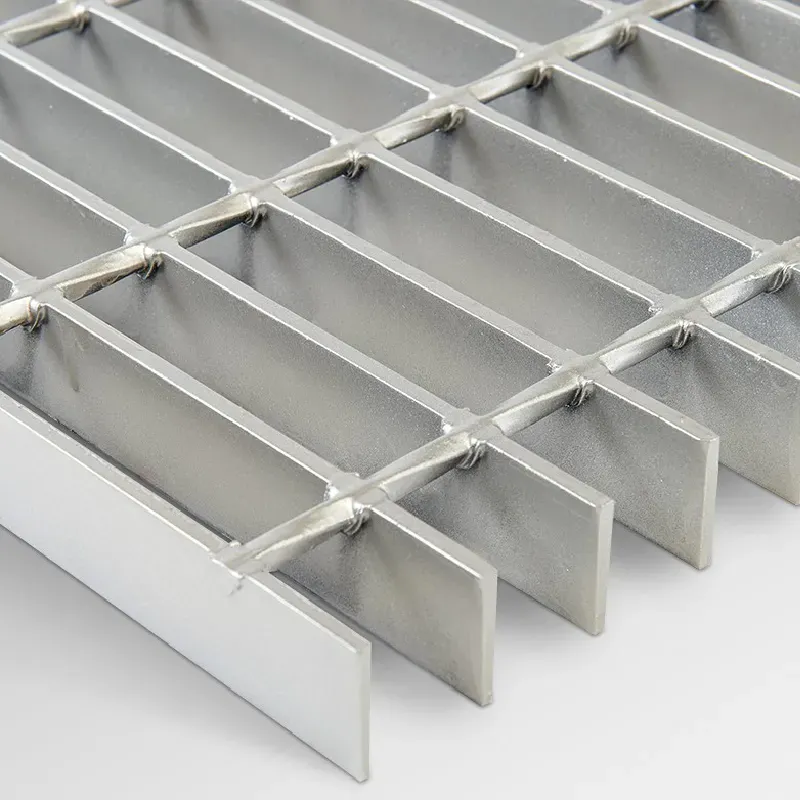

metal grating for sale

Exploring the world of metal grating and understanding load tables requires a blend of real-world experience and professional insight. Metal grating is an indispensable component in a variety of industries, providing essential support and safety features. Its application ranges from industrial floors and walkways to platforms and stair treads.

Moreover, from an authoritative perspective, credible manufacturers and industry bodies often update load tables to incorporate advancements in material technology and changes in safety regulations. Utilizing up-to-date load tables from reputable sources is imperative for maintaining safety and compliance in construction and industrial applications. Trust in metal grating load tables is apportioned not only through adherence to standards but also through the commitment of manufacturers to quality assurance. Consumers should look for certifications and accreditations that reflect a company's dedication to producing reliable and high-quality products. Trust is further reinforced by conducting third-party testing to verify the accuracy of load tables. In a product-focused evaluation, understanding these load tables enhances the product selection process. A project requiring a lightweight yet strong grating, for example, benefits from using a load table to select a high-tensile aluminum grating that meets the load requirements without adding excessive weight. In conclusion, metal grating load tables are indispensable tools that combine experience, expertise, and authority to provide trustworthy data for the safe use and optimal selection of grating products. By leveraging these tables effectively, industries can achieve superior project outcomes, bolster safety, and enhance efficiency in their operations. Whether you are an engineer, architect, or safety officer, incorporating accurate load tables into your decision-making process is a practice that upholds the highest standards of industry excellence.

Moreover, from an authoritative perspective, credible manufacturers and industry bodies often update load tables to incorporate advancements in material technology and changes in safety regulations. Utilizing up-to-date load tables from reputable sources is imperative for maintaining safety and compliance in construction and industrial applications. Trust in metal grating load tables is apportioned not only through adherence to standards but also through the commitment of manufacturers to quality assurance. Consumers should look for certifications and accreditations that reflect a company's dedication to producing reliable and high-quality products. Trust is further reinforced by conducting third-party testing to verify the accuracy of load tables. In a product-focused evaluation, understanding these load tables enhances the product selection process. A project requiring a lightweight yet strong grating, for example, benefits from using a load table to select a high-tensile aluminum grating that meets the load requirements without adding excessive weight. In conclusion, metal grating load tables are indispensable tools that combine experience, expertise, and authority to provide trustworthy data for the safe use and optimal selection of grating products. By leveraging these tables effectively, industries can achieve superior project outcomes, bolster safety, and enhance efficiency in their operations. Whether you are an engineer, architect, or safety officer, incorporating accurate load tables into your decision-making process is a practice that upholds the highest standards of industry excellence.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025