- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ก.พ. . 10, 2025 18:46

Back to list

Rope Perimeter Safety Netting

Helideck nets are indispensable safety components utilized across the aviation and maritime industries. These robust nets are engineered to ensure aircraft and personnel safety on helidecks, especially in challenging offshore and marine environments. With increasing aviation use in these demanding settings, helideck nets have steadily risen to prominence as critical safety equipment.

In recent years, technological advances have introduced innovative features in helideck net design. Enhanced visibility features, quick-release systems, and superior grip enhancements are some attributes that have revolutionized safety measures, reducing the operational risk factors significantly. The integration of these features speaks volumes about the industry's commitment to leveraging technology for enhanced safety. Understanding the dynamics of helideck operations further anchors the importance of these nets in safety protocols. Helicopters serve as lifelines for offshore industries such as oil and gas exploration, ensuring the transport of personnel and materials. Helideck nets contribute to operational stability, acting as protective barriers that prevent helicopters from skidding, especially in tumultuous weather conditions. For companies operating multimillion-dollar equipment and personnel transfer systems, the reliability of helideck nets can often mean the difference between seamless operations and costly downtimes. Investing in top-tier helideck nets, thus, presents not only a safety imperative but also a financial consideration. Regular audits, training, and updates in industry standards help maintain trust, elevating safety as a primary corporate responsibility. Ultimately, the conversation around helideck nets underscores the industry’s dedication to safety, propelled by rigorous experience, fortified expertise, recognized authority, and cemented trustworthiness. As maritime and aviation sectors continue to grow, the role of helideck nets is poised to expand, continuing to safeguard lives and machinery in a symbiotic relationship with technology and human expertise. Feel confident that with the right selection and maintenance of helideck nets, safety and operational effectiveness are firmly anchored in even the most challenging environments.

In recent years, technological advances have introduced innovative features in helideck net design. Enhanced visibility features, quick-release systems, and superior grip enhancements are some attributes that have revolutionized safety measures, reducing the operational risk factors significantly. The integration of these features speaks volumes about the industry's commitment to leveraging technology for enhanced safety. Understanding the dynamics of helideck operations further anchors the importance of these nets in safety protocols. Helicopters serve as lifelines for offshore industries such as oil and gas exploration, ensuring the transport of personnel and materials. Helideck nets contribute to operational stability, acting as protective barriers that prevent helicopters from skidding, especially in tumultuous weather conditions. For companies operating multimillion-dollar equipment and personnel transfer systems, the reliability of helideck nets can often mean the difference between seamless operations and costly downtimes. Investing in top-tier helideck nets, thus, presents not only a safety imperative but also a financial consideration. Regular audits, training, and updates in industry standards help maintain trust, elevating safety as a primary corporate responsibility. Ultimately, the conversation around helideck nets underscores the industry’s dedication to safety, propelled by rigorous experience, fortified expertise, recognized authority, and cemented trustworthiness. As maritime and aviation sectors continue to grow, the role of helideck nets is poised to expand, continuing to safeguard lives and machinery in a symbiotic relationship with technology and human expertise. Feel confident that with the right selection and maintenance of helideck nets, safety and operational effectiveness are firmly anchored in even the most challenging environments.

Share

Latest news

-

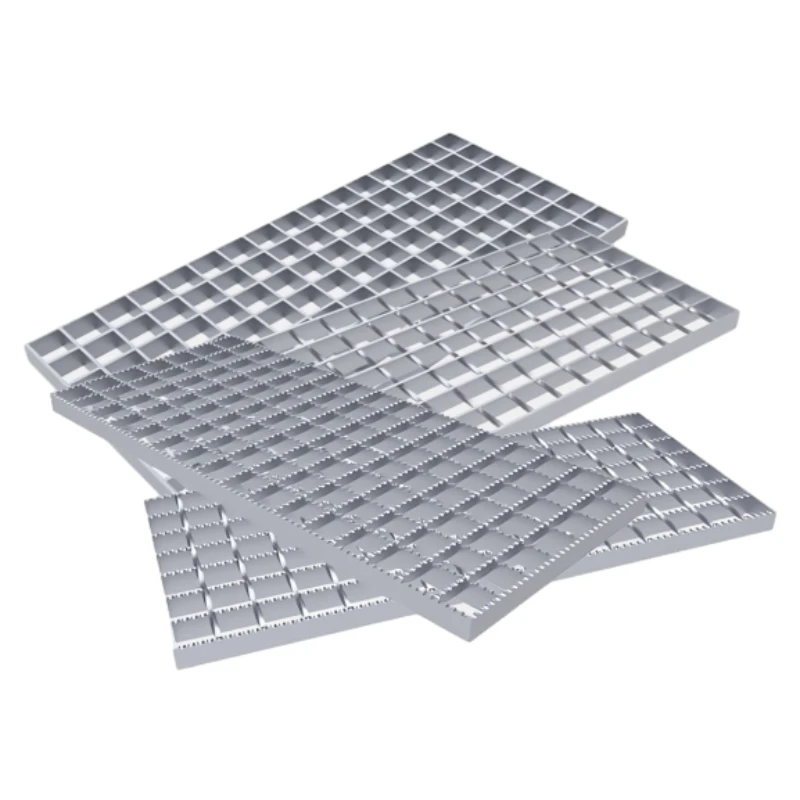

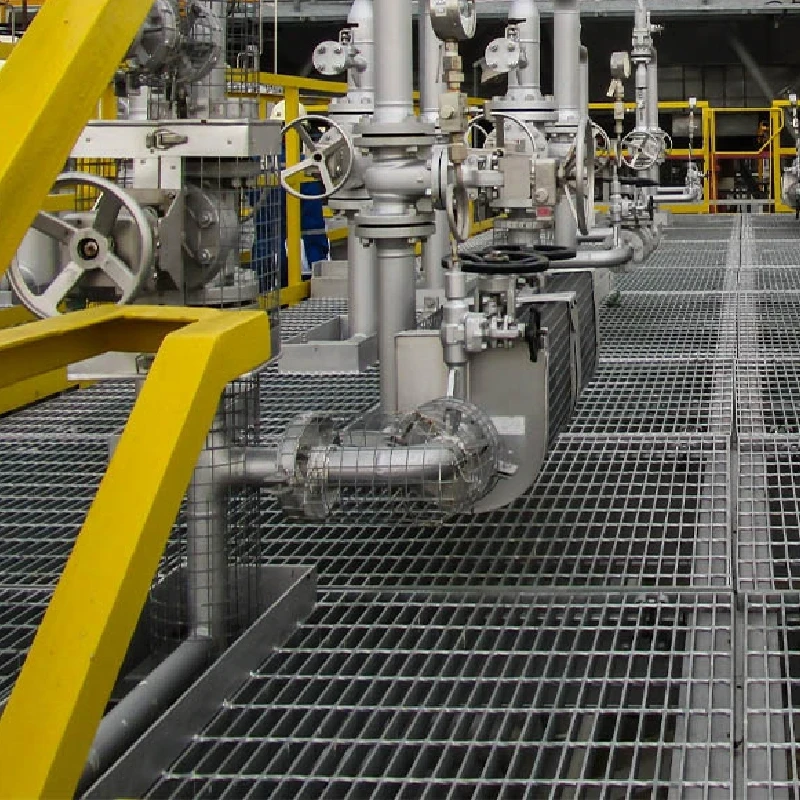

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025