- Iðnaðarsvæði, suður af Anping Town, Hengshui, Hebei, Kína.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Enska

Enska  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Enska

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

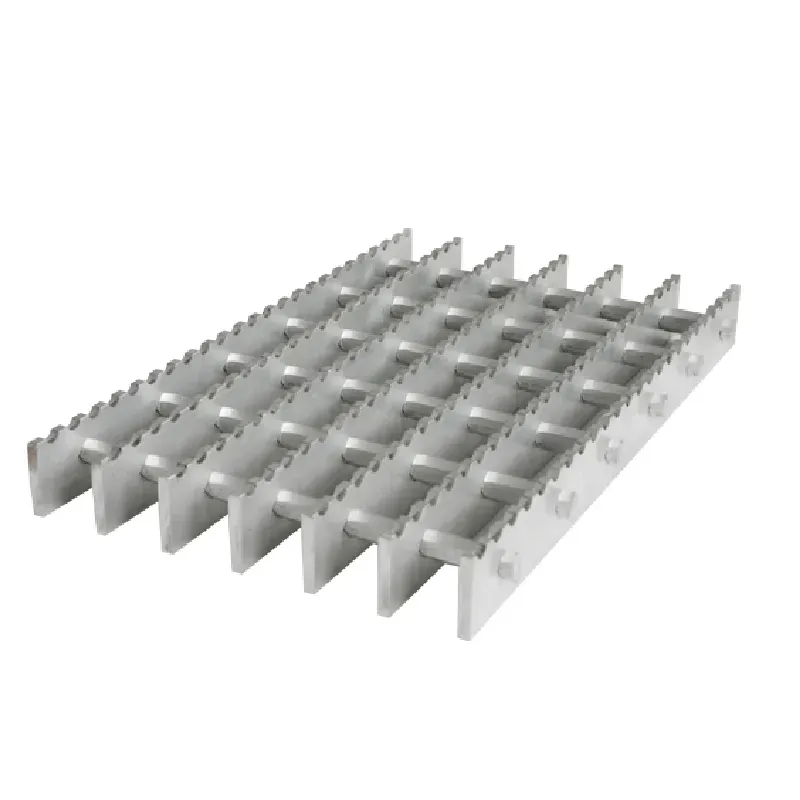

Unlocking the Value and Versatility of Steel Grating Solutions

In the realm of industrial, commercial, and architectural design, steel grating stands out as a durable, functional, and cost - effective material. From the offerings of steel grating ltd (a hypothetical entity specializing in steel grating products) to considerations of steel grating cost per square foot, steel grating flooring, and the corrosion - resistant variants of galvanized grating and galvanised grating (accounting for regional spelling differences), this versatile product serves a wide range of applications. Below, we delve into its uses, cost factors, and key considerations.

The Diverse Applications of Steel Grating Flooring

Steel grating flooring is a cornerstone in environments requiring robust, load - bearing surfaces. In industrial settings like factories and warehouses, it provides a secure platform for heavy machinery and foot traffic while allowing for easy drainage of liquids and debris. For example, in food processing plants, steel grating flooring ensures proper sanitation by preventing the buildup of moisture and waste. In architectural projects, it is used in stair treads, balconies, and walkways, offering a modern aesthetic combined with safety. The open - grid design of steel grating also enhances ventilation and light penetration, making it suitable for parking garages and outdoor observation decks.

Decoding Steel Grating Cost Per Square Foot

The steel grating cost per square foot varies based on several factors, including material type, design complexity, and customization needs. Standard carbon steel grating is often the most economical option, ideal for basic industrial uses. In contrast, galvanized grating and galvanised grating (both referring to zinc - coated steel for corrosion resistance) come at a higher cost due to the added protective layer, but offer long - term savings in maintenance and durability. For instance, in coastal or high - humidity environments, the upfront investment in galvanized grating is justified by its resistance to rust, reducing the need for frequent replacements. Customizations such as serrated surfaces for slip resistance or specific mesh sizes for aesthetic purposes can also influence the price per square foot.

The Advantages of Galvanized and Galvanised Grating

Both galvanized grating and galvanised grating (differing only in spelling based on regional preferences) offer superior protection against corrosion, making them ideal for outdoor or harsh - environment applications. The galvanization process involves coating the steel with a layer of zinc, creating a barrier that withstands exposure to moisture, chemicals, and UV rays. This makes them suitable for use in wastewater treatment plants, marine facilities, and industrial settings with high moisture levels. Additionally, the zinc coating provides a rugged, long - lasting finish that requires minimal maintenance, unlike uncoated steel which may need regular painting or sealing.

Engaging with Steel Grating Ltd (Hypothetical Entity)

A hypothetical steel grating ltd would likely offer a range of steel grating products tailored to diverse client needs. Such a company might provide standard and custom solutions, including steel grating flooring in various finishes and specifications. For example, they could offer galvanized grating for outdoor projects and uncoated steel grating for indoor industrial use. Services might include design consultations to help clients select the right grating based on load requirements, environmental factors, and budget, as well as professional installation to ensure proper fit and safety.

FAQ: Key Questions About Steel Grating

How to Choose Between Galvanized and Uncoated Steel Grating?

The choice depends on the environment. For indoor use or low - corrosion settings, uncoated steel grating may suffice and is more cost - effective. For outdoor applications, areas with high moisture, or exposure to chemicals, galvanized grating or galvanised grating is recommended for its rust resistance. Consider the long - term maintenance costs: while galvanized options have a higher upfront cost, they often save money over time by reducing the need for repairs or replacements.

What Factors Impact Steel Grating Cost Per Square Foot?

Key factors include the type of steel (carbon, stainless, or galvanized), grating size and thickness, mesh pattern, surface finish (smooth or serrated), and quantity ordered. Custom designs or specialized coatings will also increase costs. For example, a large - scale industrial project ordering standard carbon steel grating in bulk may pay less per square foot than a small - scale commercial project requiring custom - sized, galvanized grating with a unique finish.

Is Steel Grating Flooring Suitable for Heavy Machinery?

Yes, steel grating flooring is designed to handle heavy loads, making it ideal for industrial environments with heavy machinery or vehicles. The load - bearing capacity depends on the grating’s specifications, such as bar size and spacing. It’s important to consult with a supplier (such as the hypothetical steel grating ltd) to ensure the chosen grating meets the specific weight requirements of the application.

How to Maintain Galvanized Grating?

Galvanized grating requires minimal maintenance due to its corrosion - resistant coating. Regularly clean the surface with a mild detergent and water to remove dirt or debris. Inspect periodically for signs of damage to the zinc coating, such as scratches or chips, and touch up with a zinc - rich paint if necessary to maintain protection. Avoid using harsh chemicals that could damage the coating.

Can Steel Grating Be Customized for Aesthetic Projects?

Yes, steel grating can be customized in terms of mesh patterns, finishes, and colors to suit architectural or decorative needs. For example, stainless steel grating with a polished finish can add a modern touch to commercial or residential projects, while colored coatings or specific bar spacing can be used to create unique visual effects. Customization options allow steel grating ltd (hypothetical) to cater to both functional and aesthetic requirements.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingFréttirNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedFréttirNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedFréttirNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMFréttirNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipFréttirNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipFréttirNov.10,2025