- Iðnaðarsvæði, suður af Anping Town, Hengshui, Hebei, Kína.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Enska

Enska  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Enska

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

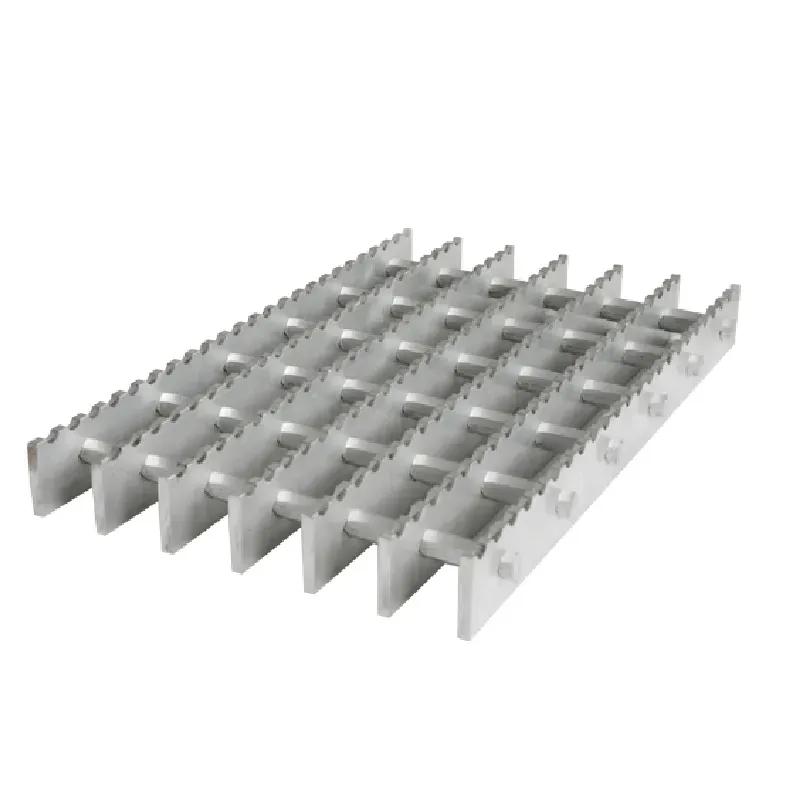

Enhancing Safety And Functionality With Industrial Floor Grating Solutions

In the realm of industrial and commercial infrastructure, the right flooring solutions are pivotal for ensuring safety, durability, and operational efficiency. Among these, flat bar grating, floor forge walkway steel galvanised grating, floor forge walkway steel grating, floor grating, and floor grating for sale stand out as essential components that combine robust design with practical utility. These grating options are engineered to withstand heavy loads, resist corrosion, and provide secure footing in diverse environments, making them indispensable for factories, warehouses, walkways, and more.

The Versatility of Flat Bar Grating

Flat bar grating is a cornerstone of industrial flooring, valued for its strength and straightforward design. Composed of parallel flat bars welded to cross bars, this grating type offers a rigid structure capable of supporting significant weights. In manufacturing facilities, flat bar grating is often used to create mezzanine floors or platforms, providing stable surfaces for machinery and personnel. Its open design allows for easy drainage of liquids and prevents the accumulation of debris, making it ideal for areas prone to spills or heavy foot traffic. The flat bars can be customized in width and spacing to meet specific load requirements, ensuring flexibility across various applications.

Durability and Corrosion Resistance of Floor Forge Walkway Steel Galvanised Grating

For environments where corrosion is a major concern, floor forge walkway steel galvanised grating offers an optimal solution. The galvanisation process coats the steel grating with a layer of zinc, providing exceptional resistance to rust and chemical damage. This makes it suitable for outdoor walkways, coastal facilities, or areas exposed to moisture, such as wastewater treatment plants. The forged steel construction ensures high tensile strength, allowing the grating to endure heavy machinery and frequent use without deforming. In industrial settings like oil refineries or chemical plants, floor forge walkway steel galvanised grating ensures long-term reliability while maintaining a safe, non-slip surface for workers.

The Practical Design of Floor Forge Walkway Steel Grating

Floor forge walkway steel grating prioritizes both functionality and ease of installation. The forged steel bars are intricately connected to form a uniform grid, offering a balance of strength and lightweight design. This type of grating is commonly used in factory walkways, allowing for quick and straightforward installation over existing structures. The open grid pattern reduces wind resistance, making it suitable for elevated walkways or outdoor catwalks. Additionally, the grating’s surface can be textured or serrated to enhance grip, minimizing the risk of slips and falls in wet or oily environments. Its adaptability makes it a popular choice for retrofitting older infrastructure or integrating into new construction projects.

Applications and Customization of Floor Grating

Floor grating encompasses a wide range of designs, from heavy-duty steel gratings to lighter aluminum options, catering to diverse industry needs. In food processing plants, floor grating with tight bar spacing prevents small particles from falling through while facilitating easy cleaning. In automotive repair shops, the grating’s open design allows for quick drainage of oils and solvents, maintaining a clean and safe workspace. Customization options include varying bar heights, spacing, and finishes, enabling businesses to tailor the grating to their specific load-bearing requirements and aesthetic preferences. Whether used in industrial kitchens, parking garages, or public transport hubs, floor grating delivers consistent performance and structural integrity.

Accessing Quality Floor Grating for Sale

For businesses seeking reliable flooring solutions, floor grating for sale offers a range of options to suit different budgets and applications. Suppliers provide grating in standard sizes or offer custom fabrication services to meet unique project demands. When purchasing, factors such as material (steel, aluminum, or stainless steel), surface finish (galvanised, powder-coated, or painted), and load capacity should be considered. Many suppliers also offer installation guidance and maintenance tips to ensure the grating remains in optimal condition. Whether for a new construction project or replacing outdated flooring, investing in high-quality floor grating for sale ensures long-term value and safety.

FAQ: Key Considerations for Industrial Grating

How to determine the appropriate load capacity for floor grating?

Assess the maximum weight that will be applied to the grating, including static loads (machinery, equipment) and dynamic loads (moving vehicles, foot traffic). Consult the manufacturer’s technical specifications to select a grating model with a load capacity that exceeds these requirements. For heavy-duty applications, such as warehouse forklift paths, prioritize gratings with thicker bars and closer spacing.

What maintenance is required for galvanised steel grating?

Galvanised grating requires minimal maintenance due to its corrosion-resistant coating. Regularly inspect for debris or contaminants that may trap moisture, and clean with a mild detergent and water as needed. Avoid using abrasive tools that could damage the zinc layer. In highly corrosive environments, periodic visual checks for coating integrity are recommended.

Can floor grating be installed outdoors?

Yes, many floor grating types, such as galvanised steel or aluminum grating, are suitable for outdoor use. Galvanised steel is particularly durable in outdoor settings, while aluminum grating offers lightweight corrosion resistance. Ensure the grating is designed for outdoor conditions, with features like anti-slip surfaces and resistance to UV degradation.

Are there aesthetic options for floor grating in commercial spaces?

Yes, suppliers offer floor grating in various finishes and designs to enhance visual appeal in commercial or public areas. Powder-coated grating in different colors, decorative bar patterns, or stainless steel finishes can complement architectural styles while maintaining functionality. This is ideal for shopping centers, stadiums, or pedestrian walkways.

How to ensure proper installation of floor grating?

Follow the manufacturer’s installation guidelines, which typically involve securing the grating to support structures using clips, welds, or bolts. Ensure the grating is level and properly aligned to distribute loads evenly. For large projects, consult a professional installer to guarantee compliance with safety standards and structural codes.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingFréttirNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedFréttirNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedFréttirNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMFréttirNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipFréttirNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipFréttirNov.10,2025