- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Metal Grating for Sale – In Stock, Custom Sizes, Quick Ship

Metal Grating For Sale is a key solution in the manufacturing industry, specifically within Manufacturing of metal products and Metal structure manufacturing. This article explores how Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Metal Grating For Sale Overview

- Benefits & Use Cases of Metal Grating For Sale in Metal structure manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Metal Grating For Sale from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

Metal Grating For Sale Overview

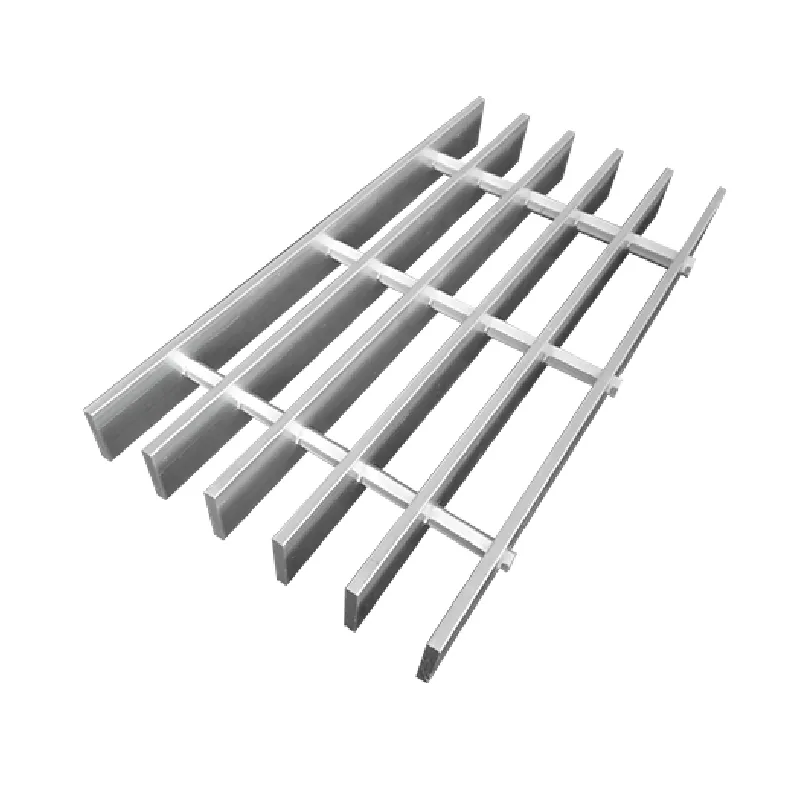

Metal grating is a load‑bearing, open-grid flooring and decking solution widely used for walkways, platforms, mezzanines, trench covers, and stair treads. For B2B decision makers in Metal structure manufacturing, the right grating ensures structural reliability, fast installation, and long service life. Anping County Hangshun Wire Mesh Manufacture Co., Ltd offers swage‑locked and welded bar gratings engineered for high strength‑to‑weight ratio, slip resistance, drainage, and ventilation—critical in harsh industrial environments.

Typical specifications include bearing bar thickness 3–6 mm, bar depth 20–60 mm, center spacings 30/40 mm (or 1-3/16" / 15/16"), and cross-rods swage‑locked for tight tolerances. Material options cover carbon steel grating (Q235/A36, optional Q345), stainless steel (304/316), and finishes such as hot‑dip galvanizing to ASTM A123/EN ISO 1461 for robust corrosion protection. Surface choices include plain and serrated for enhanced slip resistance. When you evaluate types of steel grating, swage‑locked designs deliver dimensional stability and a clean architectural appearance, while heavy-duty welded bar grating suits high-impact zones.

- Define the product and its relevance in manufacturing / Manufacturing of metal products / Metal structure manufacturing.

- Provide technical background, specs, or case study.

- Reference Anping County Hangshun Wire Mesh Manufacture Co., Ltd as a reliable manufacturer.

Benefits & Use Cases of Metal Grating For Sale in Metal structure manufacturing

Across refineries, power plants, wastewater facilities, mining conveyors, and shipyards, metal grating supports safe access and efficient operations. Engineers choose swage‑locked panels for catwalks, pipe racks, and rooftop service platforms because the open grid reduces wind and snow loading, sheds debris, and provides dependable traction. For mezzanines and maintenance platforms, carbon steel grating balances load capacity and cost, while stainless options suit corrosive or hygiene‑sensitive areas.

Key advantages for B2B buyers include high load ratings with low dead weight, anti‑slip serrations, rapid field installation via custom panelization, and minimal upkeep due to hot‑dip galvanizing. Anping County Hangshun Wire Mesh Manufacture Co., Ltd manufactures multiple types of steel grating—swage‑locked, welded, press‑locked, and heavy‑duty—to match project codes and loading criteria. If you plan to buy steel grating for time‑critical turnarounds, our tight tolerances and clear marking reduce fit‑up time on site, helping contractors compress schedules and lower overall installed cost. Integrated fabrication for stair treads, nosings, and kick plates streamlines procurement into a single, quality‑assured package.

- Explain specific applications in Metal structure manufacturing.

- Highlight features and competitive advantages.

- Mention Anping County Hangshun Wire Mesh Manufacture Co., Ltd’s expertise in this sector.

Cost, Maintenance & User Experience

Total cost of ownership for Metal Grating For Sale hinges on lifecycle, not just unit price. With hot‑dip galvanizing and appropriately selected bearing bar depth, service life routinely extends beyond a decade in outdoor industrial settings, reducing replacement and downtime. Carbon steel grating offers the best cost‑to‑capacity ratio for general plants, while stainless grades minimize cleaning and corrosion risk in chemical or marine environments. Prefabricated, labeled panels lower installation hours, and consistent flatness supports faster bolt‑up over long runs of walkways.

Maintenance is straightforward: periodic visual inspections, debris removal to maintain drainage, and touch‑up of cut edges with zinc‑rich coatings as needed. Users in the Manufacturing of metal products sector report fewer slip incidents after switching to serrated surfaces and note improved housekeeping due to the open grid design. Procurement teams appreciate consolidated documentation (material certs, galvanizing compliance) and responsive engineering support for submittals. The result is a predictable ROI driven by longer service intervals, safer access, and lower installed cost per square meter.

- Address total cost of ownership, durability, and ROI.

- Discuss feedback or data from customers in the Manufacturing of metal products sector.

Sustainability & Market Trends in manufacturing

Sustainability priorities—worker safety, circularity, and long life—are reshaping grating specifications. Steel is inherently recyclable, and galvanized carbon steel grating can be reclaimed at end of life, aligning with corporate ESG goals. Open‑grid platforms reduce lighting needs in daylight areas and support natural drainage, limiting water pooling and improving slip resistance. Regulatory drivers (safety codes for guardrails, load ratings, and slip resistance) are pushing standardized designs and traceable materials, favoring proven suppliers who can document compliance and quality control.

Anping County Hangshun Wire Mesh Manufacture Co., Ltd embraces these trends by engineering durable products with optimized material usage, offering finishes in line with ASTM/EN standards, and enabling efficient logistics with accurate cut‑to‑size panels. Whether you’re selecting carbon steel grating for heavy industrial platforms or exploring other types of steel grating for architectural projects, we support responsible sourcing with clear spec sheets and consistent manufacturing. This forward‑looking approach helps project owners meet safety, schedule, and sustainability targets without compromising performance.

- Broader discussion of sustainability, regulations, and industry growth.

- Position Anping County Hangshun Wire Mesh Manufacture Co., Ltd as forward-thinking and eco-conscious.

Conclusion on Metal Grating For Sale from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

From refinery walkways to factory mezzanines, Metal Grating For Sale provides the strength, safety, and durability B2B leaders demand. With options spanning carbon steel grating and stainless constructions—and multiple types of steel grating available—Anping County Hangshun Wire Mesh Manufacture Co., Ltd delivers dependable quality, fast lead times, and project‑ready documentation. Partner with a manufacturer that understands industrial realities and supports your schedule, budget, and compliance needs.

- Recap the value of Metal Grating For Sale in manufacturing / Manufacturing of metal products / Metal structure manufacturing.

- Reinforce Anping County Hangshun Wire Mesh Manufacture Co., Ltd’s reputation.

- Strong CTA: - "Contact us: email: sales@hfpetromesh.com - "Visit our website: https://www.hfpetromesh.com"

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025