- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Shaker Screen for Sale – Durable, API-Rated, Fast Shipping

Shaker Screen For Sale is a key solution in the Oil and Gas industry, specifically within Oil and gas exploration and production services and equipment and Drilling solid control equipment and accessories. This article explores how Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Shaker Screen For Sale Overview

- Benefits & Use Cases of Shaker Screen For Sale in Drilling solid control equipment and accessories

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Oil and Gas

- Conclusion on Shaker Screen For Sale from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

Shaker Screen For Sale Overview

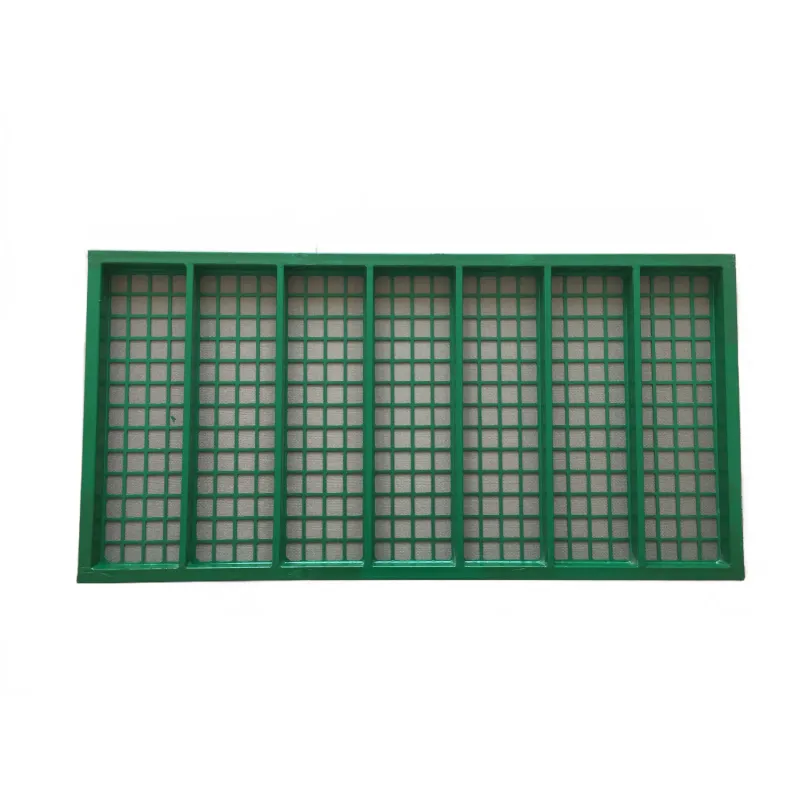

In drilling solids control, shaker screens are the first and most critical line of defense for maximizing drilling fluid recovery and protecting downstream equipment. A high-quality industrial shaker screen ensures efficient cuttings removal, stable mud properties, and lower overall mud costs. Anping County Hangshun Wire Mesh Manufacture Co., Ltd offers a Shaker Screen For Sale engineered for high throughput, precise particle control, and long service life—ideal for heavy-duty operations across exploration, development, and workover rigs.

- The product: steel-frame shale shaker screens with multi-layer stainless steel wire cloth (typically SS304/SS316), bonded to a rigid steel support for optimal strength and vibration resistance.

- Technical scope: API RP 13C compliant designation, broad mesh range (commonly API 20–325) to match formation changes and fluid programs, with flat or pyramid profiles available to balance capacity and cuttings dryness.

- Fitment: engineered options compatible with leading shaker models in the market, enabling quick change-outs and consistent sealing to minimize fluid bypass.

- Manufacturer credibility: As one of the experienced shaker screen manufacturers in Hebei’s wire mesh hub, Anping County Hangshun Wire Mesh Manufacture Co., Ltd combines precise mesh weaving, robust bonding, and strict QC to deliver predictable performance and supply reliability.

Benefits & Use Cases of Shaker Screen For Sale in Drilling solid control equipment and accessories

From spud to TD, the primary shaker drives fluid economics. Selecting a capable shaker screen directly affects ROP, hole cleaning, and nonproductive time. Hangshun’s Shaker Screen For Sale supports WBM and OBM programs across land and offshore rigs, addressing high-G shakers, high solids loading, and abrasive formations. For surface hole, operators may prioritize large-aperture screens for maximum capacity; deeper intervals often require finer API screens to protect the mud and reduce wear in desanders/desilters and centrifuges.

- Applications: top-deck scalping, fine-screen lower deck for tight cut-point control, and contingency screens for loss zones or high LCM content. The result is steadier rheology, cleaner mud, and improved shaker conveyance of cuttings.

- Advantages: strong steel frames resist bowing under high vibration; tight bonding minimizes delamination; precision mesh layering enhances separation efficiency while keeping fluid loss low; gasketed sealing edges mitigate bypass.

- Vendor expertise: As an established industrial shaker screen supplier, Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports fast turnaround, consistent quality, and technical guidance on API screen selection per formation and flow rates.

Cost, Maintenance & User Experience

For B2B decision makers, the true metric is total cost of ownership. A well-built shaker screen lowers fluid losses, protects downstream solids control assets, and reduces change-out frequency—each a lever on OPEX. Hangshun’s Shaker Screen For Sale is designed for long service under high G-force vibration, cutting downtime and labor during trips and bit runs. The steel-frame construction, reinforced mesh panels, and reliable epoxy bonding extend screen life, which translates into fewer purchases per well and more stable fluid programs.

- ROI drivers: improved mud recovery, reduced dilution, lower disposal volume, and less wear on pumps and cones due to cleaner feed. These savings often outweigh small differences in unit price.

- Maintenance tips: rotate screens by position to equalize wear, monitor for blinding, and match API ratings to flow/solids conditions. Proper tensioning and correct gasket fitment further extend life.

- User feedback: operations teams value consistent API labeling, tight tolerances, and predictable performance across batches—key assurance for multi-rig campaigns and inventory planning in oil and gas exploration and production services and equipment.

Sustainability & Market Trends in Oil and Gas

The solids control market is moving toward tighter environmental stewardship and data-driven performance. Efficient shaker separation reduces waste volumes and hydrocarbon-laden cuttings, supporting compliance with evolving regulations and ESG goals. By recovering more drilling fluid at the shakers, operators curb dilution water usage and minimize trucking and disposal costs. Durable screens also reduce scrap frequency, and stainless steel is widely recyclable, further aligning with sustainability objectives.

- Regulatory context: stricter discharge limits and waste management requirements make first-stage separation performance more valuable than ever.

- Forward-thinking approach: Anping County Hangshun Wire Mesh Manufacture Co., Ltd integrates quality control, material traceability, and application support to help operators meet performance targets responsibly. As one of the committed shaker screen manufacturers, the company emphasizes stable quality, recyclable materials, and optimized packaging to reduce transport footprint.

Conclusion on Shaker Screen For Sale from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

The right shaker screen safeguards mud quality, accelerates hole cleaning, and drives down OPEX across solids control. Anping County Hangshun Wire Mesh Manufacture Co., Ltd delivers a Shaker Screen For Sale that blends capacity, cut-point accuracy, and durability—purpose-built for demanding Oil and Gas operations. With proven steel-frame construction and a wide API range, these industrial shaker screens help B2B teams achieve consistent wellsite performance. Partner with a dependable manufacturer focused on quality and service.

- Recap: a robust solution for Oil and gas exploration and production services and equipment and Drilling solid control equipment and accessories.

- Reputation: engineered by a specialized wire mesh producer with rigorous QC and responsive after-sales support.

- Strong CTA: Contact us: email: sales@hfpetromesh.com — Visit our website: https://www.hfpetromesh.com

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025