- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Helideck Perimeter Safety Nets – Stainless, IMO-Compliant

Helideck Perimeter Safety Nets is a key solution in the transportation industry, specifically within Aviation and Maritime Equipment and Helicopter platform perimeter safety net. This article explores how Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Helideck Perimeter Safety Nets Overview

- Benefits & Use Cases of Helideck Perimeter Safety Nets in Helicopter platform perimeter safety net

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in transportation

- Conclusion on Helideck Perimeter Safety Nets from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

Helideck Perimeter Safety Nets Overview

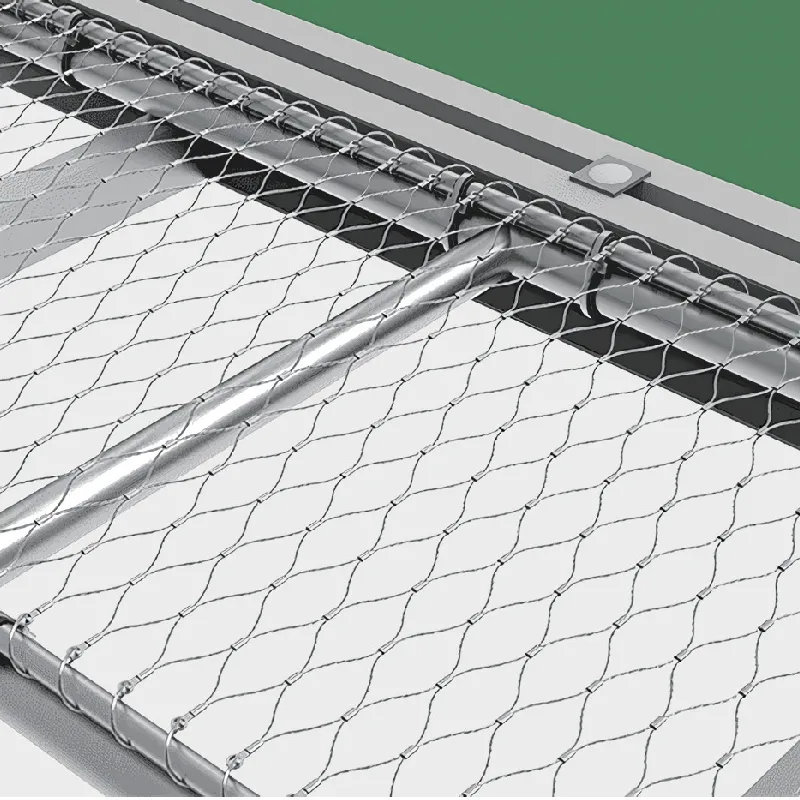

Helideck perimeter safety netting is mission-critical fall protection engineered to prevent personnel and loose equipment from dropping off the edge of a helipad during approach, landing, or rotor wash events. In Aviation and Maritime Equipment—especially offshore platforms, vessels, and rooftop helipads—this helideck perimeter net forms a robust barrier that supports compliant operations and reduces risk exposure. Built from marine-grade components, the perimeter net is designed to be flexible enough to absorb impact while maintaining structural integrity in harsh environments.

Typical configurations include stainless steel rope helipad perimeter safety netting (commonly 304/316 or 316L), with wire-rope constructions such as 7×7 or 7×19 and mesh apertures tailored to project needs. Edge ropes and integral support lanyards interface with deck structures for secure anchoring. Product options can be specified to align with accepted guidance used in the sector (e.g., CAP 437/ICAO helideck guidance where applicable) and site-specific engineering requirements. Anping County Hangshun Wire Mesh Manufacture Co., Ltd supplies custom-built helideck perimeter nets and hardware packages, providing drawings, fabrication to order, and proof documentation to help B2B stakeholders meet safety, compliance, and schedule targets.

Benefits & Use Cases of Helideck Perimeter Safety Nets in Helicopter platform perimeter safety net

Across offshore platforms, FPSOs, drillships, wind farm substations, SAR bases, hospital and commercial rooftop helipads, a helideck perimeter net mitigates the risk of fall-from-height incidents and secures loose cargo in turbulent downwash. For operators, the advantages extend beyond safety: a high‑quality helideck perimeter net enhances operational continuity, supports audits, and strengthens your safety case. Anping County Hangshun Wire Mesh Manufacture Co., Ltd engineers stainless steel perimeter safety netting to deliver high tensile strength, corrosion resistance, and long service life in saline and UV-intense environments.

Key benefits for B2B decision makers include tailored dimensions and mesh apertures, robust edge rope terminations, modular panelization for quick replacement, and compatibility with common deck materials. Competitive advantages include precision fabrication, fast lead times, and the ability to integrate complete mounting kits for streamlined installation. Whether you specify a helideck perimeter net for a newbuild or a retrofit, Hangshun’s application know-how helps you meet design intent and operational goals while maintaining compliance with your organization’s HSSE requirements.

Cost, Maintenance & User Experience

Total cost of ownership is driven by durability, inspection frequency, and ease of replacement. Stainless steel helideck perimeter safety nets—particularly 316/316L—offer superior corrosion resistance versus many polymer-only systems, reducing unscheduled changeouts and minimizing downtime. With proper installation and routine inspection, operators typically achieve multi-year service life, increasing ROI by spreading capex over a longer lifecycle and lowering opex through fewer maintenance interventions and simplified spares management.

Customers in Aviation and Maritime Equipment report clear improvements in deck safety perception, fewer corrosion-related findings during audits, and faster inspection routines thanks to the net’s clean geometry and robust terminations. Hangshun supports user experience with clear documentation, labeling for traceability, and the option for pre-assembled panels that speed installation. The result is a perimeter net solution that balances upfront cost with operational resilience—delivering predictable performance in harsh marine climates and high-traffic helipad operations.

Sustainability & Market Trends in transportation

Growth in offshore energy, emergency medical services, and distributed aviation infrastructure is expanding the installed base of helipads—and, with it, demand for reliable perimeter net solutions. Regulators and duty holders continue emphasizing fall protection, traceability, and lifecycle assurance. Stainless steel perimeter net systems support sustainability goals through long service life and high recyclability at end-of-life compared with frequent replacement of lower-durability materials. Specifying quality materials reduces waste, logistics emissions associated with replacement cycles, and disruption to critical operations.

Anping County Hangshun Wire Mesh Manufacture Co., Ltd adopts a forward‑thinking approach—prioritizing material quality, accurate fabrication, and packaging that helps minimize waste on site. By offering engineered helideck perimeter net options and documentation packages on request, Hangshun aligns with evolving standards and client ESG objectives. For B2B stakeholders, partnering with a manufacturer that delivers dependable perimeter safety netting today—and is ready for tomorrow’s compliance and sustainability expectations—helps de‑risk projects and future‑proof assets.

Conclusion on Helideck Perimeter Safety Nets from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

In demanding Aviation and Maritime Equipment environments, a high‑quality helideck perimeter net safeguards people, equipment, and uptime. Anping County Hangshun Wire Mesh Manufacture Co., Ltd delivers stainless steel rope helipad perimeter safety netting that blends compliance‑ready design, durability, and value—helping operators meet safety targets while controlling lifecycle costs. Choose a trusted manufacturer to specify perimeter safety netting that performs when it counts. Contact us: sales@hfpetromesh.com. Visit our website: https://www.hfpetromesh.com

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025