- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Shaker Screen for Sale – Durable, API-Rated, OEM Sizes

Shaker Screen For Sale is a key solution in the Oil and Gas industry, specifically within Oil and gas exploration and production services and equipment and Drilling solid control equipment and accessories. This article explores how Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Shaker Screen For Sale Overview

- Benefits & Use Cases of Shaker Screen For Sale in Drilling solid control equipment and accessories

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Oil and Gas

- Conclusion on Shaker Screen For Sale from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

Shaker Screen For Sale Overview

In drilling fluids management, the shaker screen is the first line of defense for solids control, protecting downstream equipment, preserving mud properties, and lowering overall well costs. An industrial shaker screen separates cuttings from drilling fluid on the primary shale shaker, directly influencing rate of penetration, dilution rates, and waste volumes. Anping County Hangshun Wire Mesh Manufacture Co., Ltd offers a Shaker Screen For Sale portfolio tailored for high uptime and consistent cut point control across land and offshore environments.

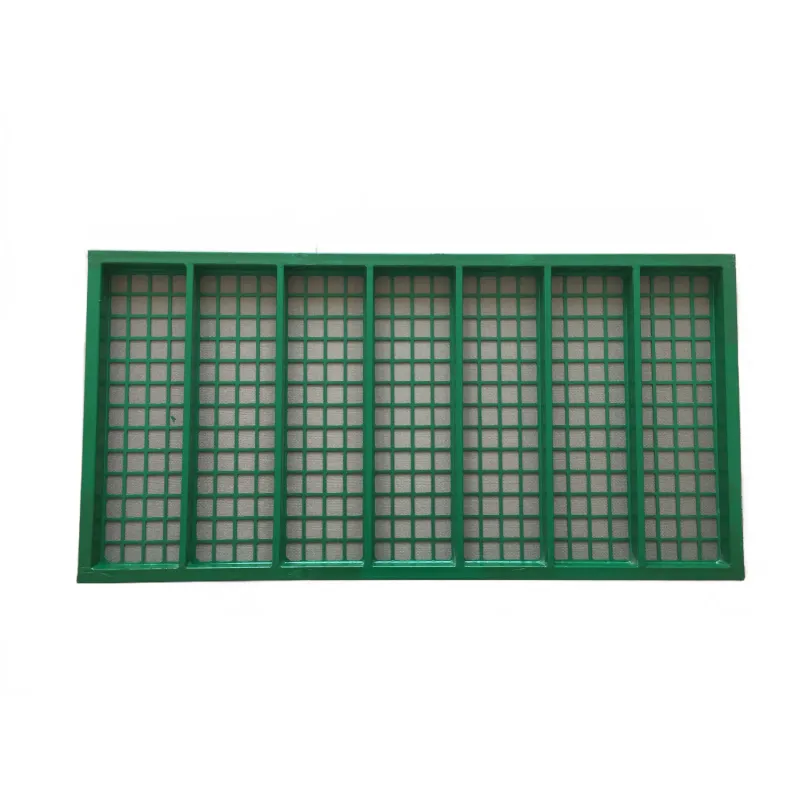

Engineered as steel-frame, pretensioned panels with multi-layer SS304/SS316L wire mesh, Hangshun screens are available in API RP 13C-compliant mesh ranges (API 20–325). Options include flat and pyramid profiles, with optimized non-blanked area, reinforced backing plates, and precision bonding for stable conductance. Common dimensions cover leading shaker footprints (e.g., MONGOOSE, FLC 500/2000, KING COBRA, and comparable models), enabling drop-in replacement without modification. A recent Middle East land rig reported steadier mud weight and reduced dilution after switching to Hangshun’s 200–230 API screens, crediting tighter mesh consistency and durable perimeter sealing. As experienced shaker screen manufacturers, Hangshun combines wire weaving expertise with rigorous quality control to serve E&P operators, drilling contractors, and mud service companies globally.

Benefits & Use Cases of Shaker Screen For Sale in Drilling solid control equipment and accessories

Across spud mud, oil-based, and synthetic-based systems, industrial shaker screens from Hangshun maintain efficient solids separation at the very start of the fluids process. Typical applications span top-hole spudding with coarser API screens, intermediate sections with medium API ranges for clay and silt control, and production sections where tighter screens safeguard mud rheology and reduce centrifuge loading. Whether drilling high-angle wells or reactive shales, the right screen improves shaker conveyance, reduces mud losses, and protects hydrocyclones and centrifuges from premature wear.

- Performance features: multi-layer mesh for cut point accuracy, pyramid profile for increased screen area, high-conductance cloth for throughput, and robust epoxy bonding to resist delamination under vibration and thermal cycling.

- Competitive advantages: API RP 13C labeling, reliable gasket sealing to minimize bypass, corrosion-resistant coatings, and compatibility with common shaker models for easy, safe change-outs.

- Expertise: Anping County Hangshun Wire Mesh Manufacture Co., Ltd leverages precision wire weaving and CNC-backed frame fabrication to deliver repeatable quality lots—key for multi-rig programs and long-term drilling campaigns.

Cost, Maintenance & User Experience

Total cost of ownership for shaker screens is driven by screen life, mud recovery, dilution, and NPT from screen failures. Hangshun’s Shaker Screen For Sale portfolio is designed to extend runtime with reinforced backing plates and consistent bonding, helping customers realize fewer change-outs and lower HSE exposure. Clients report improved ROI through reduced mud losses at the header box and steadier funnel viscosities—benefits that cascade into lower chemical additions and less wear on desanders, desilters, and centrifuges. Over a 30-day campaign, one operator documented fewer screen replacements per rig and an estimated 12–18% reduction in mud dilution cost compared to prior screens.

- Maintenance best practices: avoid metal brushes; use low-pressure washdowns; inspect for torn mesh and perimeter seal integrity; rotate screens by section to balance wear; store flat in dry conditions. Hangshun provides clear API tagging for quick QA checks at the rigsite.

- User experience: B2B teams value straightforward compatibility and stable supply. Hangshun supports bulk orders, private labeling, and rapid lead times to keep multi-rig fleets standardized and stocked.

Sustainability & Market Trends in Oil and Gas

Stricter environmental regulations and corporate ESG commitments are pushing operators to reduce waste volumes and optimize drilling fluid performance. Efficient solids control with high-quality shaker screens reduces dilution water, lowers haul-off and treatment costs for cuttings, and lessens overall environmental footprint. Market demand is trending toward API RP 13C-compliant products with traceable quality, longer service life, and safer handling features that decrease exposure during change-outs.

- Anping County Hangshun Wire Mesh Manufacture Co., Ltd positions its Shaker Screen For Sale range as part of a sustainability-forward solids control strategy: durable frames, recyclable steel components, and stable mesh specifications that keep more fluid on the rig and less waste in the skip.

- With global supply reliability and continuous process improvements, Hangshun supports drilling contractors and service companies seeking measurable ESG gains without compromising rate of penetration or well delivery timelines.

Conclusion on Shaker Screen For Sale from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

For B2B decision makers in Oil and Gas, a well-chosen shaker screen safeguards mud integrity, reduces dilution, and protects downstream assets. Hangshun’s Shaker Screen For Sale portfolio—designed and manufactured by seasoned shaker screen manufacturers—delivers API-compliant performance, robust durability, and reliable supply for drilling solid control equipment and accessories. Backed by technical support and consistent quality, it’s a smart way to drive TCO down and drilling performance up.

- Trust Anping County Hangshun Wire Mesh Manufacture Co., Ltd for dependable industrial shaker screen solutions that fit your fleet.

- Contact us: email: sales@hfpetromesh.com

- Visit our website: https://www.hfpetromesh.com

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025