- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

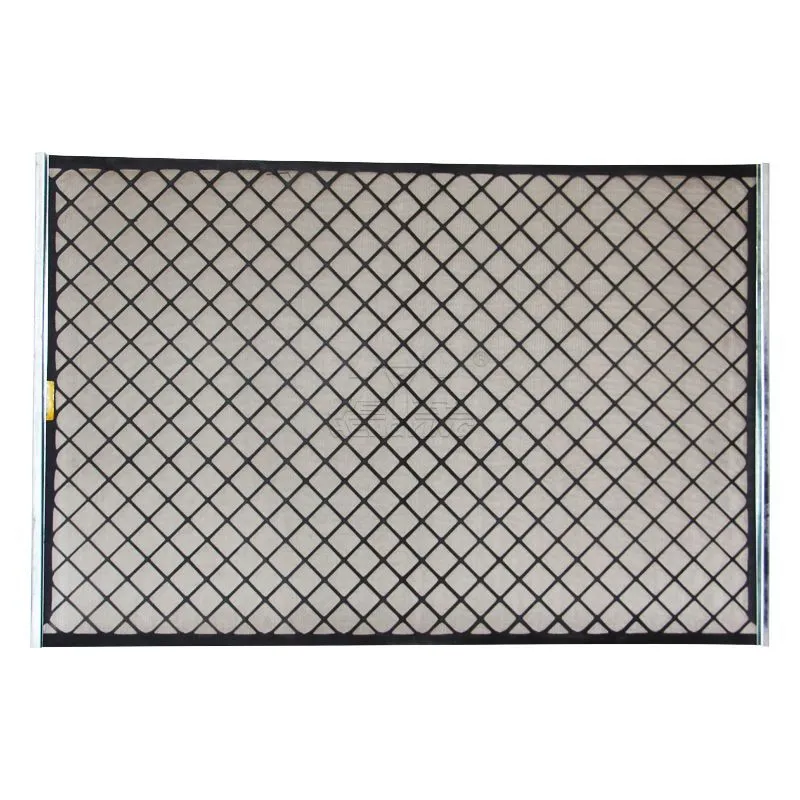

Shale Shaker Screen – Durable Mesh, Factory Price, OEM

Shale Shaker Screen is a key solution in the Oil and gas industry industry, specifically within Oil and gas equipment and services and Drilling solid control equipment and accessories. This article explores how Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Shale Shaker Screen Overview

- Benefits & Use Cases of Shale Shaker Screen in Drilling solid control equipment and accessories

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Oil and gas industry

- Conclusion on Shale Shaker Screen from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

Shale Shaker Screen Overview

A shale shaker screen is the primary filtration media on the solids control shaker—removing drilled cuttings while maximizing drilling fluid recovery. In high-activity rigs, the right shale shaker screen mesh and build quality directly influence fluid properties, rate of penetration, and overall non-productive time. Anping County Hangshun Wire Mesh Manufacture Co., Ltd designs and manufactures hook-strip soft screens with multi-layer stainless steel wire cloth (commonly SS304/SS316/SS316L), optimized open area, and stable bonding to resist blinding and delamination. Typical configurations range from API 20 to API 325, with flat and formed profiles to suit different cut-point strategies and deck motions. Dimensions are available for a wide range of OEM shakers, with tight tolerances for reliable fit-up and fast change-out. As a shale shaker screen supplier and factory in China, Hangshun delivers consistent quality at scale—backed by rigorous inspection of wire diameter, mesh count, and adhesive performance to ensure repeatable field results across land and offshore applications.

- Core role: first-stage solids control to protect downstream equipment (desanders, desilters, centrifuges) and preserve mud properties.

- Technical options: multi-layer screen mesh, corrosion-resistant materials, hook-strip soft construction, anti-blinding designs, and precise API designation.

- Reliable sourcing: Anping County Hangshun Wire Mesh Manufacture Co., Ltd is among the experienced shale shaker screen manufacturers, offering stable lead times and custom builds.

Benefits & Use Cases of Shale Shaker Screen in Drilling solid control equipment and accessories

From surface hole to deep HP/HT wells, shale shaker screens are critical for water-based and oil/synthetic-based mud systems, HDD, geothermal, and workover operations. Hangshun’s hook-strip soft screen design balances cuttings conveyance with fluid throughput, supporting stable mud weight and rheology. Optimized shale shaker screen material selection, layered mesh architecture, and robust hook-strip bonding help control blinding, extend life, and reduce change-out frequency—key advantages for B2B decision makers managing multi-rig fleets. With broad compatibility and tailored mesh selections, these screens support higher flow rates, cleaner mud, and better protection of pumps and tubulars. As a proactive shale shaker screen supplier, Hangshun offers technical guidance on mesh selection by formation type, ROP, and solids loading, ensuring screens perform consistently across campaigns.

- Applications: first-stage solids removal on primary shakers, contingency screens for high-LGS events, HDD spoil management, and waste minimization programs.

- Advantages: high open area mesh, consistent cut-point, fast installation, solid bonding to reduce delamination, and broad inventory of shale shaker screens for sale.

- Expertise: as one of the established shale shaker screen suppliers in China, Hangshun supports custom dimensions, private labeling, and fleet-wide standardization.

Cost, Maintenance & User Experience

Total cost of ownership (TCO) depends on screen life, change-out time, and mud recovery. Hangshun focuses on durable bonding, consistent mesh quality, and accurate fit to reduce unplanned screen swaps and downtime. This directly influences ROI by lowering consumable spend and protecting mud assets. For buyers comparing shale shaker screen price points, the best value comes from reliable performance in abrasive or sticky formations—where fewer failures translate into fewer trips across the shaker house and steadier drilling parameters. Customers in oil and gas equipment and services report stable performance across multiple runs, with predictable wear patterns that simplify inventory management. Preventive maintenance tips—such as inspecting shaker beds for wear, ensuring correct deck tension and screen alignment, rotating positions between high- and low-impact panels, and using proper washdown practices—extend screen life while keeping solids removal on spec. Hangshun’s responsive support and clear labeling streamline ordering, helping procurement teams consolidate SKUs and secure competitive pricing for shale shaker screens for sale.

- Lower TCO: longer service life, fewer change-outs, better mud recovery.

- Procurement confidence: consistent quality from a shale shaker screen manufacturer with flexible MOQs and steady lead times.

Sustainability & Market Trends in Oil and gas industry

Stricter environmental expectations and cost controls are reshaping solids control. Effective primary screening reduces waste volumes, optimizes cuttings dryness, and increases drilling fluid recovery—lowering haul-off, additives consumption, and overall carbon intensity. In parallel, regulations and operator standards emphasize API screen designation practices, traceability, and safer handling. Hangshun aligns with these market trends by emphasizing durable shale shaker screen material, recyclable steel components, and efficient packaging that reduces transport footprint. As a forward-thinking shale shaker screen supplier and factory, Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports fleet standardization, technical mesh selection, and continuous improvement—helping drilling contractors and service companies meet performance and sustainability goals. With expanded capacity in shale shaker screen China manufacturing, Hangshun strengthens supply continuity while maintaining the quality expected by international buyers seeking competitive shale shaker screen price and assured delivery.

- Sustainability levers: improved mud recovery, reduced waste logistics, and longer screen life.

- Market trend: greater focus on compliance, traceability, and supplier resilience across global projects.

Conclusion on Shale Shaker Screen from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

For drilling operations where fluid integrity and uptime are non-negotiable, a high-quality Shale Shaker Screen is essential. Hangshun delivers durable mesh construction, precise fit, and dependable supply—making it a strong choice for Oil and gas equipment and services and Drilling solid control equipment and accessories. Backed by experience among shale shakerscreen manufacturers and supported by practical field guidance, Hangshun is a trusted partner for B2B buyers seeking value and performance in shale shaker screen mesh and compatible screens for sale.

- Choose proven quality, competitive pricing, and reliable delivery from a reputable shale shaker screen supplier.

- Contact us: email: sales@hfpetromesh.com

- Visit our website: https://www.hfpetromesh.com

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025