- Iðnaðarsvæði, suður af Anping Town, Hengshui, Hebei, Kína.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Enska

Enska  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Enska

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

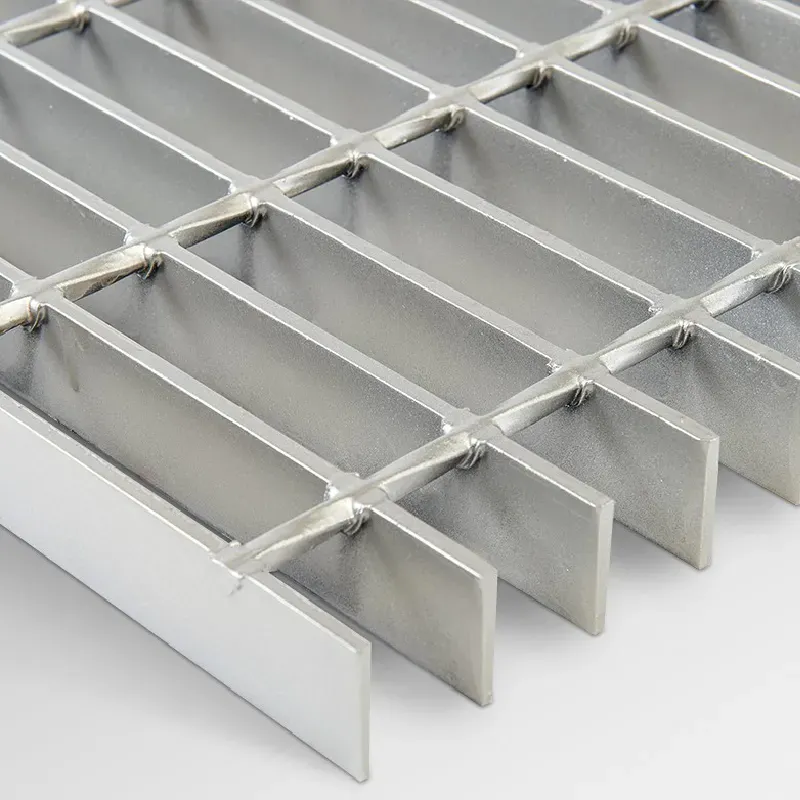

Elevating Industrial And Architectural Design With Premium Grating Solutions

In the realms of construction, manufacturing, and architectural innovation, the right grating solutions can seamlessly blend functionality, safety, and aesthetics. Among the standout options are 19W4 grating, 19W4 serrated grating, 19W4 steel grating, 316 stainless steel grating, and 4 expanded metal grating, each engineered to meet specific demands across diverse applications. These gratings offer unique advantages, from heavy - duty load - bearing capabilities to corrosion resistance and visual appeal, making them essential components in a wide range of projects.

Unraveling the Versatility of 19W4 Grating

19W4 grating is a robust choice for industrial and commercial settings that require reliable load - bearing performance. This type of grating is characterized by its precise grid pattern and durable construction. In warehouses or manufacturing facilities, 19W4 grating can be used as flooring to support heavy machinery and foot traffic. Its open design allows for easy drainage of liquids and the passage of air, making it suitable for areas where spillage or ventilation is a concern. For example, in food processing plants, the grating’s ability to prevent the accumulation of moisture or debris helps maintain hygiene standards while providing a stable surface for workers and equipment.

The Enhanced Traction of 19W4 Serrated Grating

19W4 serrated grating takes the functionality of standard 19W4 grating a step further by incorporating serrated edges on the bearing bars. This design feature significantly enhances traction, making it an ideal choice for environments where slip resistance is critical. In outdoor walkways, ramps, or areas exposed to wet conditions, the serrations on 19W4 serrated grating reduce the risk of slips and falls. Industrial settings such as oil refineries or chemical plants, where surfaces may be contaminated with oils or other slippery substances, also benefit from this type of grating. The serrations provide a secure foothold for workers, even when wearing heavy - duty boots, ensuring safety without compromising on the grating’s structural integrity.

The Strength and Durability of 19W4 Steel Grating

19W4 steel grating is prized for its exceptional strength and durability, making it a go - to option for heavy - duty applications. Constructed from high - quality steel, this grating can withstand extreme loads, making it suitable for use in industrial platforms, mezzanines, and stair treads. In steel mills or heavy equipment manufacturing facilities, 19W4 steel grating provides a stable and reliable surface that can endure the constant movement of heavy machinery and the impact of falling materials. The steel’s inherent rigidity ensures that the grating maintains its shape and performance over time, even in harsh industrial environments where corrosion or abrasion is a concern.

The Corrosion Resistance of 316 Stainless Steel Grating

316 stainless steel grating is a premium solution designed for environments where corrosion resistance is of utmost importance. The addition of molybdenum to the stainless steel alloy gives 316 stainless steel grating superior resistance to corrosion from chemicals, saltwater, and other aggressive substances. This makes it an excellent choice for coastal applications, marine environments, or facilities that handle corrosive materials. In pharmaceutical or food and beverage production plants, where strict hygiene standards and resistance to cleaning agents are required, 316 stainless steel grating ensures long - term performance without compromising on safety or cleanliness.

The Versatile Design of 4 Expanded Metal Grating

4 expanded metal grating offers a unique combination of strength, lightness, and visual appeal. Created by slitting and stretching a metal sheet, this grating features a diamond - shaped pattern that provides both open area and structural integrity. In architectural applications, 4 expanded metal grating can be used as decorative panels, balcony guards, or room dividers, adding a modern and industrial aesthetic to buildings. Its lightweight design also makes it easy to install, reducing labor costs and time. In agricultural settings, the grating can be used as fencing or animal enclosures, allowing for proper ventilation while keeping animals secure.

FAQ: Key Considerations for Grating Selection and Use

How to determine the appropriate grating type for a specific project?

Choosing the right grating depends on factors such as the intended use, load requirements, environmental conditions, and aesthetic preferences. For heavy - duty industrial applications, 19W4 steel grating or 19W4 serrated grating may be suitable due to their strength and slip resistance. In corrosive environments, 316 stainless steel grating is the preferred choice. For architectural or decorative purposes, 4 expanded metal grating offers design flexibility. Always consult the grating’s technical specifications to ensure it meets the project’s load and safety requirements.

What maintenance practices are recommended for steel and stainless steel gratings?

Regular maintenance can extend the lifespan of steel and stainless steel gratings. For 19W4 steel grating, inspect for signs of rust or damage and apply a protective coating as needed to prevent corrosion. For 316 stainless steel grating, clean with a mild detergent and water to remove dirt or contaminants, especially in harsh environments. Avoid using abrasive cleaners that could scratch the surface and compromise its corrosion resistance. Periodically check for loose or damaged bars and repair or replace them promptly to maintain the grating’s structural integrity.

Can expanded metal grating be customized for specific design needs?

Yes, 4 expanded metal grating can be customized in terms of sheet thickness, opening size, and finish to suit specific design requirements. Manufacturers can also fabricate the grating into various shapes and sizes, making it suitable for unique architectural features or non - standard installations. Custom finishes, such as powder coating or galvanizing, can enhance the grating’s aesthetic appeal and provide additional protection against the elements.

What is the load - bearing capacity of 19W4 grating?

The load - bearing capacity of 19W4 grating varies depending on the specific dimensions and material used. Generally, it is designed to withstand heavy loads, making it suitable for industrial and commercial applications. To determine the exact load capacity for a particular project, refer to the manufacturer’s technical data sheet, which provides detailed information on the grating’s load - carrying capabilities under different conditions.

Is serrated grating more expensive than standard grating?

Serrated grating, such as 19W4 serrated grating, may have a slightly higher cost than standard grating due to the additional manufacturing process required to create the serrated edges. However, the enhanced safety and functionality it provides in slippery or high - traffic environments often justify the extra expense. When comparing costs, consider the long - term benefits, such as reduced risk of accidents and maintenance costs, that serrated grating can offer.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingFréttirNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedFréttirNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedFréttirNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMFréttirNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipFréttirNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipFréttirNov.10,2025