- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Durable Perimeter Net for Superior Safety & Security

Elevating Safety Standards: The Critical Role of Perimeter Netting Solutions

In industrial and infrastructural sectors where elevated platforms and critical access points are prevalent, the implementation of robust safety measures is paramount. Among these, specialized netting solutions are indispensable for preventing falls and containing debris. Our focus today is on advanced perimeter net systems, particularly the high-performance Chain Link Helipad Perimeter Safety Netting.

These engineered solutions are not merely barriers; they are integral safety components designed to mitigate risks in high-stakes environments, ensuring the safety of personnel and operational integrity. From offshore oil rigs to urban hospital rooftops, the demand for reliable perimeter safety netting continues to grow, driven by stringent regulatory compliance and an unwavering commitment to operational excellence.

Industry Trends in Advanced Perimeter Safety Solutions

The landscape of industrial safety is continually evolving, with several key trends shaping the development and deployment of advanced perimeter netting solutions:

- Enhanced Regulatory Scrutiny: Global and local aviation authorities (e.g., FAA, EASA, ICAO) are increasingly tightening safety regulations for helipad design and operation, directly impacting the specifications for safety barriers and fall protection systems. This drives demand for certified and compliant perimeter safety net products.

- Demand for Corrosion-Resistant Materials: Especially in maritime and coastal environments, the lifecycle cost of safety infrastructure is significantly influenced by material durability. There is a strong trend towards using highly corrosion-resistant materials like marine-grade stainless steel or heavily galvanized and PVC-coated steel for perimeter netting.

- Integration with Smart Technologies: Emerging trends include incorporating IoT sensors for structural integrity monitoring, automated inspection systems, and real-time data analytics for proactive maintenance, although this is more nascent for passive barriers like netting.

- Customization and Modular Design: With diverse architectural and operational requirements across various sites (e.g., offshore platforms, building rooftops, ships), there's a growing need for highly customizable and modular perimeter netting systems that can adapt to unique geometries and load specifications without compromising safety or aesthetics.

- Focus on Sustainable Solutions: While secondary to safety, an increasing emphasis on environmentally friendly manufacturing processes and materials that offer extended service life and recyclability is also influencing product development.

Understanding Chain Link Helipad Perimeter Safety Netting: Technical Specifications

Chain Link Helipad Perimeter Safety Netting is engineered to meet the rigorous demands of aviation safety, providing a robust and reliable barrier. The design focuses on high-strength, low-maintenance materials capable of withstanding extreme environmental conditions and significant impact forces.

Key Structural and Material Parameters:

- Wire Material: Typically high-grade galvanized steel (hot-dip galvanized per ASTM A123) or marine-grade stainless steel (e.g., AISI 304, 316) for superior corrosion resistance. PVC coating over galvanized wire is common for enhanced durability and aesthetics.

- Wire Gauge: Ranging from 9 gauge (3.76mm) to 6 gauge (4.88mm), depending on required tensile strength and impact resistance. Heavier gauges offer greater protection.

- Mesh Aperture: Standard diamond mesh sizes typically range from 1 inch (25mm) to 2 inches (50mm). Smaller apertures increase debris retention capability and deter smaller objects from passing through.

- Tensile Strength: Wires possess a minimum tensile strength of 400-550 MPa, ensuring the netting can absorb significant energy without catastrophic failure.

- Coating Thickness: For galvanized options, a zinc coating of at least 2 oz/ft² (610 g/m²) is standard. PVC coating typically ranges from 0.4mm to 1.0mm in thickness.

- Frame Structure: Supported by robust steel posts and rails, often hot-dip galvanized or powder-coated for longevity, designed to integrate seamlessly with the helipad structure.

Typical Product Specification Table: Chain Link Helipad Perimeter Safety Netting

| Parameter | Specification | Standard Met / Notes |

|---|---|---|

| Material | Hot-dip Galvanized Steel / PVC Coated Galvanized Steel / Stainless Steel (304/316) | ASTM A123, ASTM A641, ASTM A492 |

| Wire Gauge | 9 Gauge (3.76mm) - 6 Gauge (4.88mm) | Specific to application load requirements |

| Mesh Aperture | 1.5" x 1.5" (38mm x 38mm) standard, 1" to 2" options | Optimized for personnel safety and FOD retention |

| Tensile Strength | Min. 550 MPa (for wire) | Conforms to ISO 6892-1 |

| Coating Thickness | Zinc: 610 g/m² (min); PVC: 0.8 mm (min) | ASTM B6 for zinc, custom for PVC |

| Panel Height | Typically 1.2m (4 ft) or 1.5m (5 ft) | Compliant with ICAO Annex 14 Volume II Helidromes |

| Service Life | 20+ years (dependent on environment and maintenance) | Estimated under normal operating conditions |

Manufacturing Process Flow of Perimeter Netting

The production of high-quality perimeter netting is a meticulously controlled process, ensuring product integrity and compliance with stringent safety standards. Our manufacturing adheres to ISO 9001 quality management principles, with specific material and testing standards guided by industry benchmarks like ASTM and ANSI.

Schematic Steps:

- Material Sourcing & Preparation: High-carbon steel rods are sourced, meeting specific chemical composition requirements. These rods undergo rigorous inspection before being drawn into wires of the desired gauge. For stainless steel, specific alloy grades are selected.

- Wire Drawing: The steel rods are processed through multiple dies to achieve the precise wire diameter required for the specified mesh strength. This process enhances the tensile strength and uniformity of the wire.

- Weaving/Knitting Process: Wires are fed into automated chain-link weaving machines. These machines interlink the wires to form the characteristic diamond-patterned mesh, ensuring consistent mesh aperture and strong interconnections.

- Post-Weaving Treatment (Galvanization): For galvanized steel options, the woven mesh panels undergo hot-dip galvanization. This involves immersing the mesh in a bath of molten zinc, forming a metallurgically bonded, corrosion-resistant coating that meets or exceeds ASTM A123 standards.

- PVC Coating (Optional): If specified, galvanized mesh is then coated with UV-stabilized PVC. This is typically achieved through an extrusion or fluid bed dipping process, providing an additional layer of corrosion protection, aesthetic appeal, and enhanced durability against environmental factors.

- Frame Fabrication & Assembly: Support posts, rails, and connection hardware are precision-fabricated from structural steel, often via CNC machining for accuracy. These components are typically hot-dip galvanized or powder-coated.

- Quality Control & Testing: Throughout the process, materials and finished products are subjected to rigorous testing. This includes tensile strength tests (ISO 6892-1), coating thickness measurements (ASTM B6, ASTM A90), salt spray tests (ASTM B117) for corrosion resistance, and visual inspections for weave consistency and dimensional accuracy. Our products adhere to international standards such as ISO and ANSI.

- Final Inspection & Packaging: Completed chain link helipad perimeter safety netting panels and associated hardware undergo a final comprehensive inspection before being securely packaged for shipment, protecting them from damage during transit.

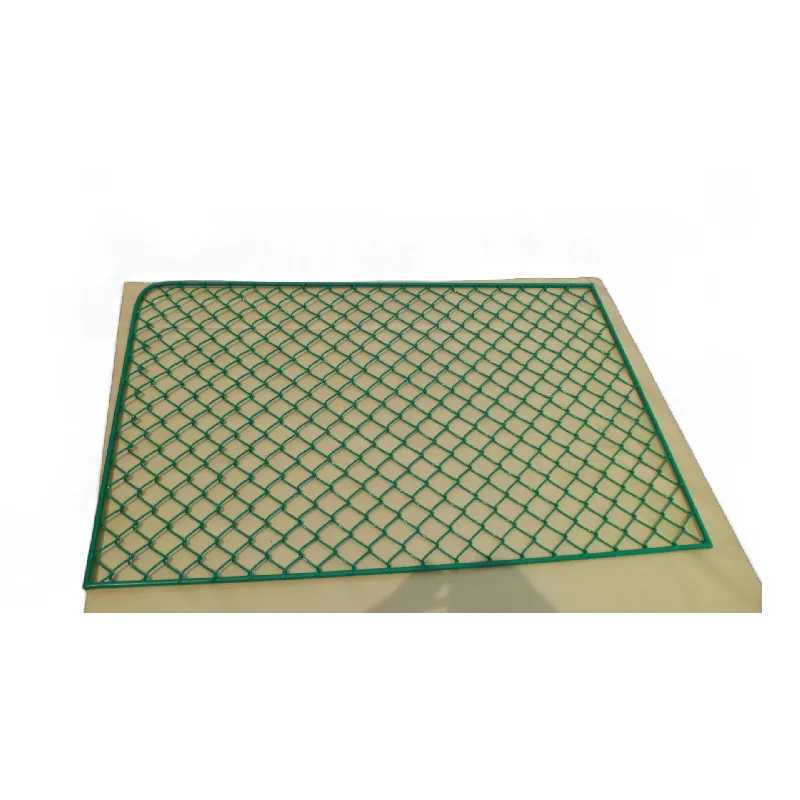

Image: Precision weaving of perimeter net wires for uniform mesh.

Technical Advantages and Performance Characteristics

The inherent design and material selection of our perimeter netting offer distinct advantages, contributing to its superior performance and longevity:

- Exceptional Corrosion Resistance: Through hot-dip galvanization and optional PVC coating, our netting systems exhibit outstanding resistance to rust and degradation from saltwater, industrial pollutants, and harsh weather, significantly extending service life to over 20 years, even in highly corrosive marine or industrial environments.

- High Tensile Strength & Impact Absorption: The interlocked chain link design, combined with high-gauge steel wire, provides excellent tensile strength and the ability to absorb significant impact energy, crucial for containing debris or preventing falls from heights. This design ensures personnel safety, a key advantage in petrochemical and metallurgy sectors.

- Durability & Longevity: Engineered for continuous exposure to demanding conditions, the robust construction minimizes the need for frequent replacement, offering a superior return on investment compared to lesser quality alternatives. This translates to energy saving in terms of resources and reduced operational disruption.

- Low Maintenance Requirements: The high-quality coatings and robust materials demand minimal upkeep, reducing ongoing operational costs and ensuring uninterrupted safety performance.

- Compliance with Aviation Safety Standards: Our helipad perimeter safety netting designs adhere to international aviation standards such as ICAO Annex 14 Volume II Helidromes, ensuring regulatory compliance and peace of mind for operators.

- Versatile Application: While optimized for helipads, the inherent strength and durability make these systems suitable for general industrial fall protection and security perimeters in diverse sectors, including water supply & drainage infrastructure.

Application Scenarios and Target Industries

The robust and versatile nature of Chain Link Helipad Perimeter Safety Netting makes it ideal for a wide array of high-risk environments. Its primary application focuses on helipad safety, but its characteristics extend its utility across various demanding industries.

- Helipads (Onshore & Offshore): Essential for preventing personnel and equipment from falling off elevated helipads, including those on offshore oil & gas platforms, marine vessels (frigates, cruise ships), hospital rooftops, and corporate headquarters. The netting contains potential Foreign Object Debris (FOD) that could interfere with aircraft operations.

- Petrochemical Facilities: Used around elevated walkways, equipment platforms, and processing units where fall protection and security are critical. The corrosion resistance is particularly beneficial in these chemically active environments.

- Metallurgy Plants: Provides safety barriers around hot processing areas, casting platforms, and elevated work zones, protecting workers from falls and containing potential spatter or small falling objects.

- Water Supply & Drainage Infrastructure: Employed as safety fencing around reservoirs, treatment plants, elevated pump stations, and hazardous access points to prevent unauthorized access and ensure personnel safety during maintenance.

- Industrial Safety Zones: General applications in factories, warehouses, and construction sites for demarcation of hazardous areas, fall arrest, and equipment segregation.

Image: Chain link helipad perimeter safety netting installed on an elevated platform.

Comparison: Chain Link Perimeter Netting vs. Alternatives

When selecting a perimeter net system, it's crucial to evaluate various options against specific operational demands. While several solutions exist, chain link netting presents a compelling balance of cost-effectiveness, durability, and compliance for many applications, especially helipads.

Perimeter Safety Netting Comparison Table

| Feature / Type | Chain Link Perimeter Safety Netting | Rigid Panel Fencing (e.g., Welded Mesh) | Flexible Rope/Knotless Netting |

|---|---|---|---|

| Primary Material | Galvanized/PVC Coated Steel, Stainless Steel | Welded Galvanized/Powder-Coated Steel | High-Tenacity Polypropylene, Nylon, HDPE |

| Durability & Service Life | Excellent (20+ years), highly corrosion resistant | Very Good (15-25 years), depends on coating integrity | Good (5-15 years), prone to UV degradation and wear |

| Impact Absorption | High flexibility and energy absorption, ideal for falling objects/personnel | Moderate, can deform or crack under heavy impact | Excellent, highly elastic for energy dissipation |

| Installation Complexity | Moderate, requires tensioning and proper post-attachment | Moderate, panel rigidity simplifies alignment but requires robust fastening | High, intricate tensioning and securing to avoid sagging |

| Maintenance | Low, occasional inspection for damage/tension | Low, occasional inspection for rust/damage | High, requires regular UV checks, restitching, replacement |

| Cost (Material & Installation) | Moderate | Moderate to High | Low (material), High (specialized installation) |

| Suitability for Helipads | Highly Recommended (balance of durability, FOD retention, cost) | Good, but less impact-absorbent and potentially higher cost | Good for fall arrest, but limited FOD retention, shorter lifespan in harsh environments |

This comparison highlights why chain link perimeter netting remains a preferred choice for critical applications like helipads. It offers a robust, long-lasting, and cost-effective solution with excellent safety characteristics, addressing both personnel fall protection and FOD containment efficiently.

Customized Solutions and Engineering Capabilities

Recognizing that no two projects are identical, we specialize in providing bespoke perimeter netting solutions. Our engineering team works closely with clients to design and fabricate systems that perfectly integrate with existing infrastructure and meet unique operational demands.

- Tailored Dimensions & Configurations: Whether it’s a non-standard helipad shape, a multi-level industrial platform, or an irregularly shaped containment area, we can customize mesh panel dimensions, post heights, and mounting configurations to ensure complete coverage and compliance.

- Specific Material Grades & Coatings: Beyond standard galvanized and PVC-coated options, we can offer specialized alloys (e.g., Duplex Stainless Steel for extreme marine environments) or high-performance coatings (e.g., epoxy-based) for enhanced chemical resistance or specific aesthetic requirements.

- Integration with Ancillary Systems: Our designs can seamlessly integrate with lighting systems, safety signage, access gates, and existing structural elements, ensuring a cohesive and functional safety solution.

- Structural Engineering Support: We provide comprehensive engineering calculations and design validation to ensure the proposed perimeter safety net system can withstand anticipated wind loads, impact forces, and environmental stresses, adhering to relevant building codes and safety standards (ee.g., ASCE 7 for wind loads).

- Project Management: From initial consultation and conceptual design to fabrication, delivery, and installation guidance, our team manages the entire project lifecycle, ensuring timely and on-budget execution.

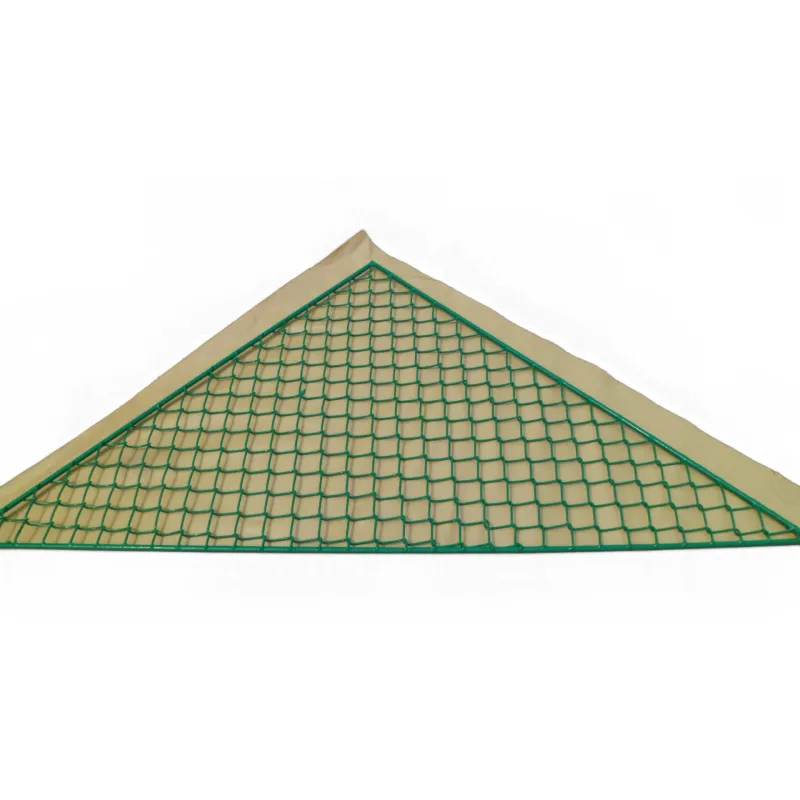

Image: Tailored perimeter netting solution demonstrating custom design capabilities.

Real-World Application Case Studies

Case Study 1: Offshore Oil & Gas Platform Helipad Upgrade

Client: Major International Energy Corporation

Challenge: An aging helipad on an offshore platform required an immediate upgrade to its perimeter safety system. The existing netting had succumbed to severe galvanic corrosion due to constant exposure to saltwater spray and high humidity. The new solution needed to be highly durable, resistant to extreme marine environments, and quick to install to minimize operational downtime.

Solution: We engineered and supplied a customized perimeter netting system utilizing marine-grade AISI 316 stainless steel chain link mesh with an additional specialized polymer coating. The modular design allowed for pre-fabrication on shore, significantly reducing on-site installation time. Our team provided detailed installation diagrams and remote technical support to the platform's engineering crew.

Outcome: The new chain link helipad perimeter safety netting system was installed within a critical 72-hour operational window, ensuring minimal disruption to helicopter operations. The client reported a significant improvement in the safety rating of the helipad and anticipates a service life exceeding 25 years due to the superior materials and coatings. This project showcased our expertise in delivering corrosion-resistant solutions for demanding environments.

Case Study 2: Metropolitan Hospital Rooftop Helipad Enhancement

Client: Leading Urban Healthcare Provider

Challenge: A busy hospital rooftop helipad needed to enhance its fall protection system to meet updated ICAO and local aviation authority standards. Key requirements included a visually unobtrusive design, rapid installation with minimal noise and disruption to hospital operations, and robust protection against accidental falls and FOD.

Solution: We provided a custom-designed, PVC-coated galvanized perimeter netting system. The PVC coating (in a neutral grey color) offered excellent weather resistance and blended seamlessly with the building’s aesthetics. The system was designed with quick-connect modular panels that allowed for installation during off-peak hours, significantly reducing noise and minimizing any impact on patient care.

Outcome: The helipad's safety perimeter was upgraded efficiently, fully complying with all new regulatory requirements. The hospital commended the discreet aesthetic of the netting and the professional, low-impact installation process. The enhanced perimeter safety net now provides a secure environment for emergency medical helicopter operations, demonstrating our commitment to tailored solutions and client-centric service.

Trustworthiness and Client Assurance

Our commitment to quality, reliability, and client satisfaction is fundamental to our operations. We build trust through transparent processes, certified products, and unwavering support.

- Certifications: Our manufacturing facilities and processes are ISO 9001:2015 certified, guaranteeing adherence to international quality management standards. Products consistently meet or exceed relevant ASTM, ANSI, and ICAO standards.

- Partner Clients: We proudly serve a diverse portfolio of clients, including leading energy companies, major industrial operators, governmental agencies, and commercial aviation entities worldwide. Our long-standing relationships attest to our product quality and service excellence.

- Years of Service: With X years of dedicated service in the specialized netting industry, our extensive experience provides unparalleled expertise in engineering, manufacturing, and deploying robust safety solutions.

- Lead Time & Fulfillment: Standard product orders typically have a lead time of 3-4 weeks from order confirmation, depending on volume and customization. Complex, custom-engineered perimeter net solutions may require 6-8 weeks for design, fabrication, and quality assurance. We prioritize efficient logistics to ensure timely delivery.

- Warranty Commitments: We offer a comprehensive 10-year warranty against manufacturing defects and material failures under normal operating conditions. Specific material corrosion warranties may extend up to 20 years for galvanized and stainless steel components.

- Customer Support: Our dedicated customer support team provides expert technical assistance, installation guidance, and comprehensive after-sales service. We are committed to ensuring the long-term performance and satisfaction with every perimeter safety net system supplied.

Image: Rigorous quality assurance protocols for perimeter netting systems.

Frequently Asked Questions (FAQ)

Q: What are the primary materials used in your Chain Link Helipad Perimeter Safety Netting?

A: Our netting is primarily constructed from high-grade hot-dip galvanized steel wire, often with an additional PVC coating for enhanced corrosion resistance and aesthetics. For extremely harsh environments, marine-grade stainless steel (AISI 304 or 316) options are available.

Q: What is the expected service life of your perimeter net systems?

A: With proper installation and minimal maintenance, our galvanized and PVC-coated perimeter netting systems are designed for a service life of 20 years or more, even in challenging industrial and marine conditions.

Q: How is the perimeter safety net typically installed?

A: The netting panels are securely fastened to a robust steel frame structure, consisting of posts and rails. Installation typically involves welding, bolting, or specialized clamping mechanisms to ensure structural integrity. We provide detailed installation manuals and technical support.

Q: Are custom sizes and designs available for your perimeter netting?

A: Absolutely. We specialize in customized solutions. Our engineering team can work with your specifications to design and fabricate netting systems with tailored dimensions, mesh sizes, material grades, and configurations to perfectly fit your project requirements.

Q: What international standards do your chain link helipad perimeter safety netting products meet?

A: Our products are manufactured to stringent quality standards, including ISO 9001:2015. Material specifications comply with ASTM (e.g., A123, A641, B6) and ANSI standards. Our helipad netting designs specifically adhere to ICAO Annex 14 Volume II Helidromes recommendations for perimeter safety.

Conclusion

The selection of an appropriate perimeter safety net is a critical decision for any high-risk environment. Our Chain Link Helipad Perimeter Safety Netting offers a superior blend of material strength, corrosion resistance, and engineering precision, making it an ideal choice for ensuring unparalleled safety and operational continuity across diverse industrial applications. By adhering to rigorous manufacturing processes and international standards, we deliver solutions that provide long-term reliability and peace of mind.

For expert consultation, tailored solutions, or a detailed quotation, please contact our technical sales team. We are ready to assist you in securing your elevated platforms and critical access points with the most dependable perimeter netting available.

References

- International Civil Aviation Organization (ICAO). (2018). Annex 14, Volume II: Aerodromes, Helidromes. 5th Edition. ICAO Publications.

- ASTM International. (2020). Standard Specification for Zinc-Coated (Galvanized) Steel Barbed Wire. ASTM A121/A121M-20. West Conshohocken, PA: ASTM International.

- ISO. (2016). Metallic materials — Tensile testing — Part 1: Method of test at room temperature. ISO 6892-1:2016. Geneva, Switzerland: International Organization for Standardization.

- National Fire Protection Association (NFPA). (2022). Standard for Aircraft Rescue and Fire-Fighting Services at Airports. NFPA 403. Quincy, MA: NFPA.

- The Engineering ToolBox. (2023). Galvanized Steel - Corrosion Resistance. Available at: [Authoritative engineering resource website, e.g., EngineeringToolBox.com].

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025