- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Top Manufacturers of Shale Shaker Screens for Oil and Gas Industry

The Importance of Shale Shaker Screens in the Oil and Gas Industry

Shale shaker screens are vital components in the oil and gas industry, specifically in the drilling process. These screens are designed to separate drilling cuttings from the drilling fluid, ensuring that the latter remains usable and effective throughout the drilling cycle. The significance of shale shaker screens cannot be overstated; they contribute to the efficiency, safety, and overall performance of drilling operations. In this article, we will explore the different types of shale shaker screens, the manufacturers behind them, and their impact on the industry.

Understanding Shale Shaker Screens

Shale shakers are the first line of defense in the solid control system of drilling operations. They use a series of vibrating screens to remove unwanted solids from the drilling fluid, which contains a mixture of water, clay, and other materials. The performance of these shakers is largely dependent on the design and material of the screens. Common types of shale shaker screens include flat screens, pyramid screens, and serrated screens, each with distinct advantages in terms of separation efficiency and lifespan.

The materials used to manufacture these screens are crucial. High-quality screens are often made from composite materials or stainless steel to improve durability and resistance to wear and tear. The mesh size and layout also play essential roles in determining the effectiveness of the separation process. Manufacturers continuously innovate by developing new screen designs that can handle various drilling conditions, from shallow wells to ultra-deep offshore drilling.

Key Manufacturers of Shale Shaker Screens

The market for shale shaker screens is competitive, with several manufacturers leading the charge in technology and innovation

. Among the renowned brands are Derrick, Brandt, and NOV (National Oilwell Varco), each known for their high-quality products and commitment to ongoing research and development.- Derrick As a pioneer in the solids control industry, Derrick is noted for its innovative screen designs, such as the hyperpool and the dual-motion shale shakers. Their screens are widely regarded for their superior performance in solid-liquid separation. - Brandt Another prominent player, Brandt offers a range of screens that cater to different drilling environments. Their cutting-edge technology focuses on maximizing both efficiency and lifespan, thus providing significant savings in operational costs.

shale shakerscreen manufacturers

- NOV (National Oilwell Varco) NOV is a global leader in providing equipment for oil and gas drilling. Their shale shaker screens are designed using the latest technology, ensuring optimal performance even in the most challenging conditions.

Additionally, there are several other smaller manufacturers who are also making waves in the industry, offering customized solutions tailored to specific drilling needs.

The Impact of Shale Shaker Screens on Drilling Operations

The efficiency of shale shaker screens directly impacts drilling operations. An effective screen can minimize the loss of drilling fluids, reduce downtime, and lower drilling costs. Properly functioning screens also contribute to safer drilling environments, as keeping the drilling fluid clean reduces the risk of equipment failure and potential accidents.

Moreover, with the growing emphasis on environmental sustainability, manufacturers are now focusing on producing screens that facilitate better fluid recycling and minimize waste generation. This is in line with the industry’s overall push towards more sustainable and environmentally responsible practices.

Conclusion

In summation, shale shaker screens are indispensable to the oil and gas drilling process. The ongoing advancements by leading manufacturers not only enhance the efficiency and safety of drilling operations but also contribute to broader sustainability efforts within the industry. As drilling technologies continue to evolve, the role of shale shaker screens will likely expand, paving the way for innovative approaches to enhance their performance and utility. Understanding the importance of these components is crucial for stakeholders in the oil and gas sector, as they play a pivotal role in achieving operational excellence and sustainability in challenging environments.

-

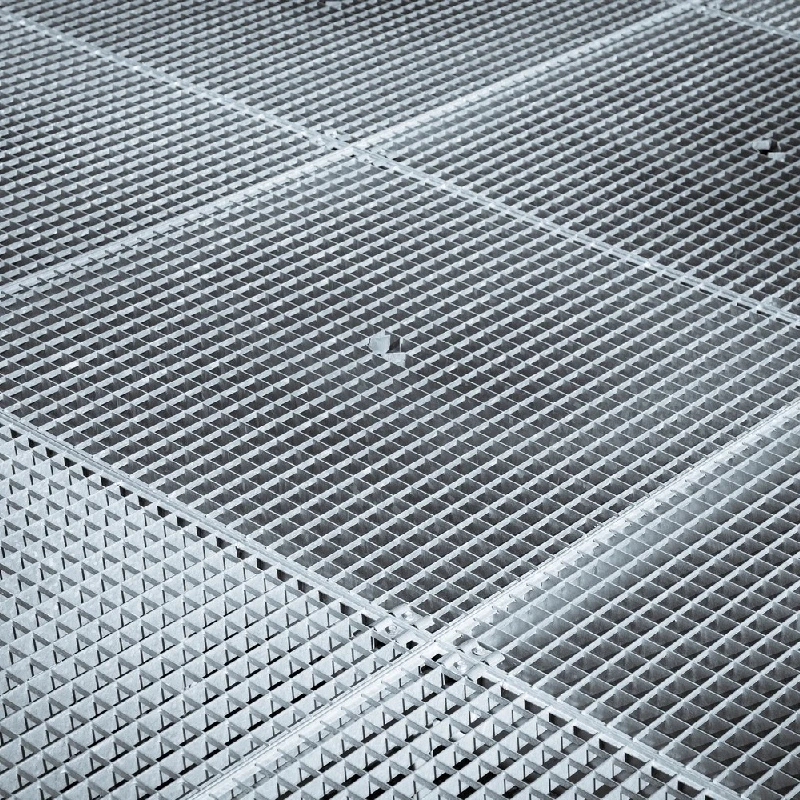

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025