- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

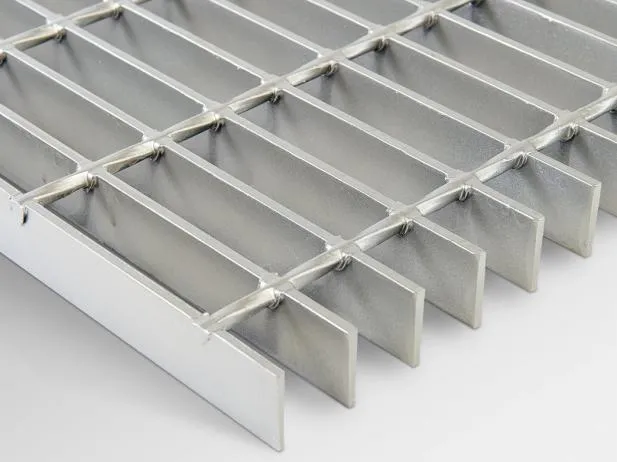

Galvanized Steel Grating for Durable Industrial Flooring Solutions and Applications

Understanding Grating Galvanized Steel A Practical Solution for Industrial Needs

Grating galvanized steel has become a popular choice in various industrial applications, thanks to its robust nature, durability, and corrosion resistance. This material is a perfect blend of functionality and strength, making it ideal for a wide range of environments, from manufacturing plants to outdoor spaces.

Galvanization is the process of applying a protective zinc coating to steel or iron, which helps prevent rust and corrosion. This process significantly enhances the lifespan of steel products, particularly in environments prone to moisture, chemicals, and harsh weather conditions. By utilizing galvanized steel in the grating form, industries can ensure that their structures endure the test of time while maintaining safety standards.

One of the primary advantages of grating galvanized steel is its slip resistance. The open design of grating allows for effective drainage while providing a secure walking surface. This feature is particularly essential in environments where spills or debris can create slippery conditions, such as in factories or outdoor walkways. The non-slip surface of galvanized steel grating minimizes the risk of accidents, contributing to a safer work environment.

Moreover, grating galvanized steel is lightweight yet extremely strong. This combination makes it easier to install and handle compared to other materials. Its high load-bearing capacity ensures that it can support significant weight without bending or breaking, making it suitable for applications such as flooring, walkways, and platforms. Industries often choose this material for its ability to withstand heavy traffic and the rigors of daily use.

grating galvanized steel

Another significant benefit of galvanized steel grating is its low maintenance requirement. The zinc coating not only protects the steel from corrosion but also reduces the need for frequent inspections or repairs. Once installed, galvanized steel grating can be left to perform its function without the constant worry of degradation. This aspect is particularly appealing for companies looking to reduce operational costs and downtime.

Furthermore, grating galvanized steel can be customized to meet specific project requirements. It is available in various sizes, shapes, and load ratings, allowing businesses to select the appropriate type for their unique needs. Whether it is for a pedestrian walkway, a heavy-duty industrial platform, or drainage systems, there is a galvanized steel grating solution available.

In terms of environmental impact, galvanized steel is also a sustainable choice. The material is recyclable, and the galvanization process itself has evolved to be more eco-friendly. Steel’s longevity means fewer resources are consumed for replacements, contributing positively to sustainability efforts.

In conclusion, grating galvanized steel stands out as an indispensable material in industrial applications. Its remarkable durability, safety features, low maintenance requirements, and adaptability make it a wise investment for businesses seeking reliable, long-term solutions. As industries continue to seek materials that offer both performance and sustainability, grating galvanized steel will remain a preferred choice for many years to come.

-

Upgrade Your Industrial Operations with Durable Steel GratingNewsJul.21,2025

-

Transform Your Flooring Solutions with Quality Floor GratingNewsJul.21,2025

-

Top-Quality Shale Shaker Screens for Your Drilling NeedsNewsJul.21,2025

-

High-Quality Steel Grating for All Your Industrial NeedsNewsJul.21,2025

-

Explore the Durability and Versatility of Galvanized Steel GratingNewsJul.21,2025

-

Ensure Maximum Safety with Premium Safety NetsNewsJul.21,2025