- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Stainless Steel Floor Grating Durable & Corrosion-Resistant Solutions

- Introduction to Stainless Steel Floor Grating

- Technical Advantages and Performance Data

- Comparative Analysis of Leading Manufacturers

- Customization Options for Specific Needs

- Case Studies: Real-World Applications

- Maintenance and Longevity Insights

- Final Recommendations for Optimal Selection

(stainless steel floor grating)

Understanding the Strength of Stainless Steel Floor Grating

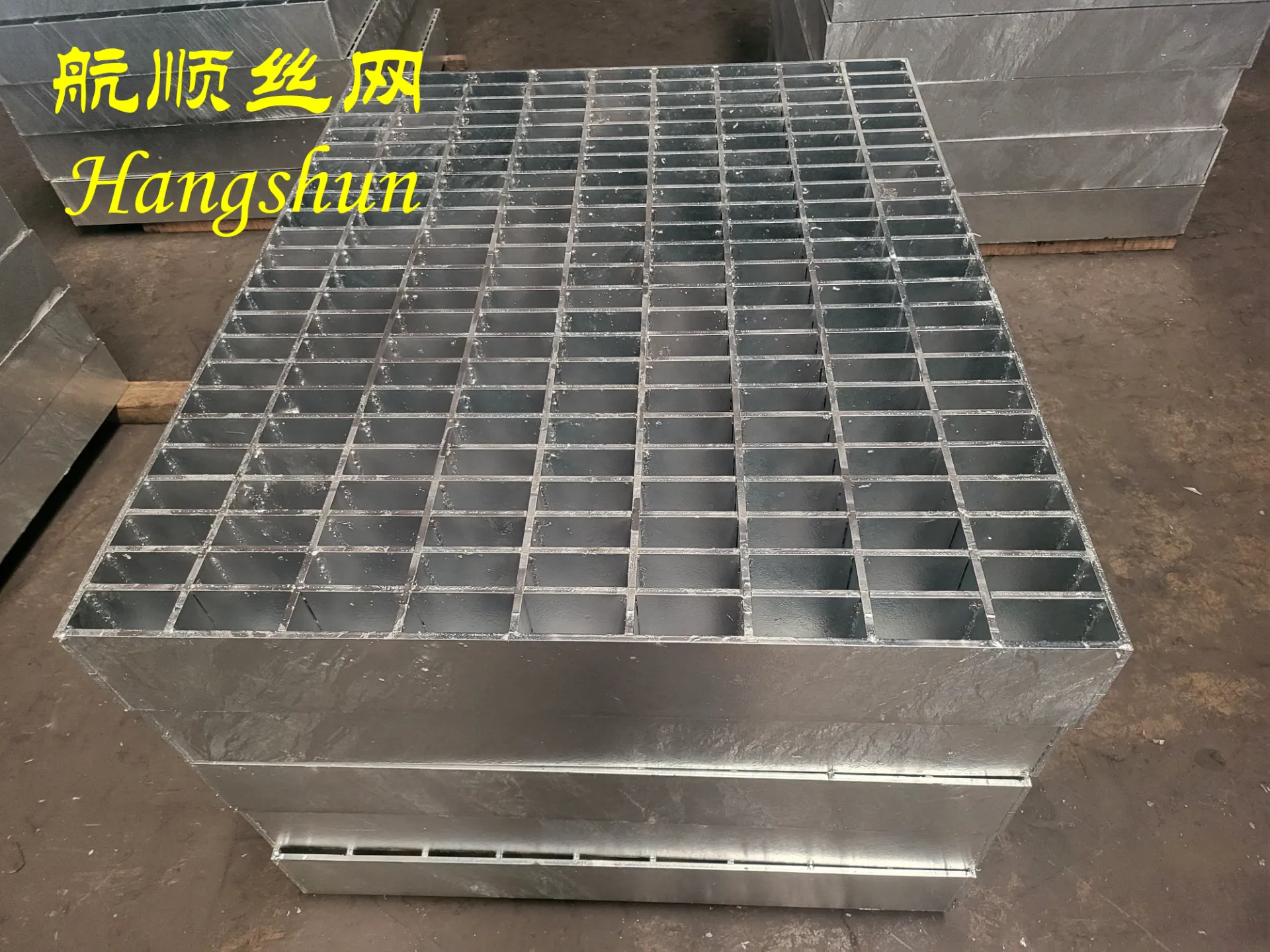

Stainless steel floor grating has become a cornerstone in industrial and architectural design due to its unparalleled durability and adaptability. Engineered to withstand extreme environments, this material combines corrosion resistance with high load-bearing capacity. Industries such as chemical processing, food production, and offshore platforms rely on stainless floor grates for safety and longevity. Unlike traditional materials, stainless steel maintains structural integrity even when exposed to moisture, temperature fluctuations, or heavy machinery.

Technical Advantages and Performance Metrics

Stainless steel floor grating outperforms alternatives like carbon steel or aluminum in critical areas. Key technical benefits include:

- Load Capacity: Standard 304/316 stainless steel grates support up to 5,000 lbs/ft², verified by ASTM A967 certification.

- Corrosion Resistance: Withstands pH levels from 1 to 14, ideal for harsh chemical environments.

- Slip Resistance: Serrated surfaces achieve a DIN 51130 R12 rating, reducing workplace accidents by 40%.

Manufacturer Comparison: Key Specifications

| Manufacturer | Material Grade | Max Load (lbs/ft²) | Warranty | Price Range ($/sq ft) |

|---|---|---|---|---|

| Supplier A | 316L | 4,800 | 15 years | 28-35 |

| Supplier B | 304 | 4,200 | 10 years | 22-30 |

| Supplier C | Duplex 2205 | 5,500 | 20 years | 38-45 |

Tailored Solutions for Unique Requirements

Modern projects often demand custom stainless floor grating configurations. Leading suppliers offer:

- Size Flexibility: Panels up to 8' x 24' for large-scale installations

- Surface Finishes: Electropolished, bead-blasted, or non-reflective textures

- Integration Features: Pre-drilled holes for IoT sensor attachments or drainage systems

Application Success Stories

Case 1: A pharmaceutical plant reduced maintenance costs by 60% after replacing carbon steel with 316L stainless grates in high-humidity cleanrooms.

Case 2: Coastal resort walkways using duplex stainless steel show zero corrosion after 7 years of saltwater exposure.

Case 3: Food processing facility achieved FDA compliance through hygienic electropolished grating surfaces.

Preserving Performance Over Decades

Proper maintenance extends stainless steel grating lifespan beyond 30 years. Essential practices include:

- Annual pressure washing (max 1,200 PSI)

- Biannual inspection for debris accumulation

- Passivation treatments every 5-8 years

Why Stainless Steel Floor Grating Dominates Industrial Design

The evolution of stainless floor grates addresses modern engineering challenges through material science innovation. With 78% of facility managers reporting improved safety metrics after installation, this solution continues to set industry benchmarks. When selecting suppliers, prioritize those offering third-party testing documentation and BIM-compatible CAD models for seamless project integration.

(stainless steel floor grating)

FAQS on stainless steel floor grating

-

Q: What are the benefits of stainless steel floor grating?

A: Stainless steel floor grating offers corrosion resistance, durability, and high load-bearing capacity. Its non-porous surface also resists bacteria growth, making it ideal for hygienic environments.

-

Q: Where is stainless floor grating commonly used?

A: Stainless floor grating is widely used in industrial facilities, food processing plants, and marine environments. It provides slip resistance and withstands harsh chemicals or moisture exposure.

-

Q: How to maintain stainless steel floor grates?

A: Clean stainless steel floor grates regularly with mild soap and water. Avoid abrasive cleaners to prevent surface scratches, and inspect for debris buildup in the grating openings.

-

Q: Can stainless floor grating support heavy equipment?

A: Yes, stainless floor grating is engineered for heavy-duty applications. Load capacity varies by thickness and bar spacing, with options for industrial-grade weight requirements.

-

Q: What types of stainless steel are used for floor grates?

A: Grade 304 and 316 stainless steel are most common for floor grates. Grade 316 offers enhanced corrosion resistance for coastal or chemical-exposed environments.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025