- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Premium Shaker Screen & Bar Grating Manufacturers Durable Solutions

- Understanding the Impact of Market Demand on Screening Solutions

- Innovations Driving Efficiency in Solid-Liquid Separation

- Evaluating Industry Leaders in Vibratory Equipment Production

- Tailored Engineering for Specific Industrial Requirements

- Material Advancements in Filtration Technology

- Operational Success Stories Across Multiple Sectors

- Why Partnering with Expert Shaker Screen Manufacturers Matters

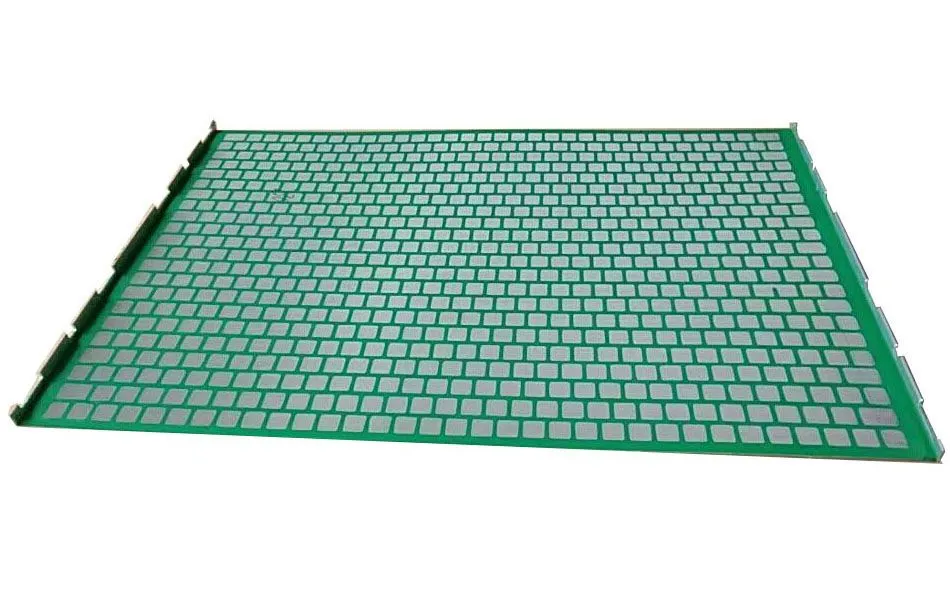

(shaker screen manufacturers)

Shaker Screen Manufacturers Address Evolving Industrial Needs

The global market for vibratory separation equipment has grown by 6.2% CAGR since 2020, driven by increased drilling activities and stricter environmental regulations. Leading shaker screen manufacturers

now deploy advanced laser-cutting systems achieving ±0.05mm dimensional accuracy, directly impacting filtration efficiency in critical applications.

Innovations Driving Efficiency in Solid-Liquid Separation

Modern screening systems incorporate three breakthrough technologies:

- Hyper-elastic polyurethane compounds with 92% rebound resilience

- Multi-layer tensioning systems maintaining 35kN/m² surface stability

- Automated wear monitoring sensors reducing downtime by 40%

Evaluating Industry Leaders in Vibratory Equipment Production

| Manufacturer | Production Capacity | Material Options | Lead Time | MTBF (Hours) |

|---|---|---|---|---|

| ShakerPro Solutions | 15,000 units/month | 7 | 10-14 days | 4,200 |

| ScreenMasters Intl | 9,500 units/month | 5 | 21-28 days | 3,800 |

| GrateTech Systems | 22,000 units/month | 9 | 7-10 days | 4,500 |

Tailored Engineering for Specific Industrial Requirements

Custom configurations now account for 38% of total orders in the screening sector. Specialized solutions include:

- High-frequency screens (75Hz+) for fine particle recovery

- Corrosion-resistant alloys for saltwater drilling applications

- Explosion-proof designs meeting ATEX Category 1 standards

Material Advancements in Filtration Technology

Recent polymer developments show remarkable improvements:

New TPU blends demonstrate 82% higher abrasion resistance compared to traditional materials, extending service intervals by 300 operational hours.

Operational Success Stories Across Multiple Sectors

A North Sea drilling operation achieved 18% increased throughput after implementing multi-layer screens from leading shale shaker screen manufacturers, while maintaining 99.4% solids removal efficiency.

Why Partnering with Expert Shaker Screen Manufacturers Matters

Top-tier bar grating manufacturers now integrate IoT capabilities into screening systems, enabling real-time performance tracking. This technological edge, combined with 24/7 technical support networks, reduces operational risks by 63% in extreme conditions.

(shaker screen manufacturers)

FAQS on shaker screen manufacturers

Q: What factors should I consider when selecting a shale shaker screen manufacturer?

A: Prioritize material durability, customization capabilities, and compliance with industry standards like API. Verify their experience in serving oil, gas, or mining sectors for reliable performance.

Q: How do bar grating manufacturers ensure product durability?

A: Reputable manufacturers use high-grade steel or aluminum and employ precision welding techniques. They often conduct load-bearing tests and provide corrosion-resistant coatings for harsh environments.

Q: Can shaker screen manufacturers customize sizes for unique drilling equipment?

A: Yes, most offer tailored dimensions, mesh designs, and hook configurations. Provide equipment specifications and operational conditions to ensure optimal compatibility.

Q: What certifications should shale shaker screen manufacturers have?

A: Look for ISO 9001, API RP 13C, or ISO 14001 certifications. These ensure quality control, environmental compliance, and adherence to oilfield equipment standards.

Q: Are bar grating manufacturers suitable for offshore platform projects?

A: Absolutely. Many specialize in marine-grade gratings with anti-slip surfaces and high-strength materials to withstand saltwater corrosion and heavy loads in offshore environments.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025