- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

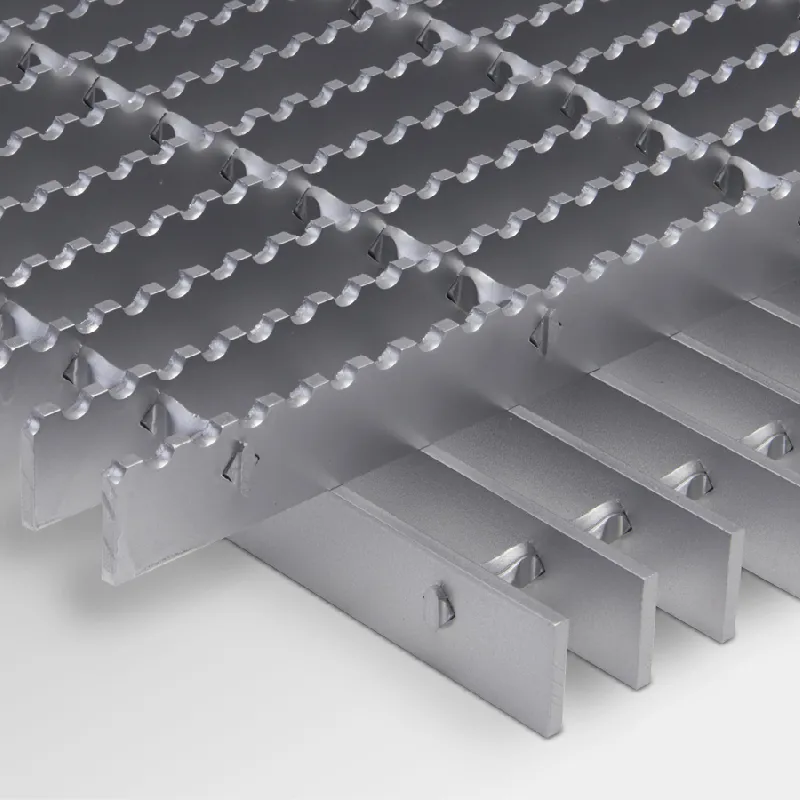

Durable Floor Metal Grating Slip-Resistant & Heavy-Duty Solutions

- Introduction to Floor Metal Grating Solutions

- Technical Advantages & Load-Bearing Data

- Material Comparison: Leading Manufacturers Analyzed

- Customization Options for Specialized Requirements

- Installation Best Practices & Safety Metrics

- Industry-Specific Application Case Studies

- Future Trends in Metal Floor Grating Systems

(floor metal grating)

Essential Strength for Modern Infrastructure

Industrial and commercial facilities increasingly specify floor metal grating

as their primary walkway solution, with global demand projected to grow at 4.8% CAGR through 2030 (Grand View Research). This surge stems from three critical factors:

- 40% weight reduction compared to solid flooring systems

- 86% faster liquid drainage in wet environments

- 5x higher corrosion resistance versus polymer alternatives

Engineering Superiority in Load Management

Advanced manufacturing techniques enable metal floor grating to achieve unprecedented performance benchmarks:

| Specification | Mild Steel | Aluminum | Stainless 316 |

|---|---|---|---|

| Max Load Capacity (PSF) | 850 | 620 | 1,100 |

| Temperature Tolerance (°F) | -20 to 900 | -100 to 400 | -300 to 1,500 |

Manufacturer Performance Breakdown

Third-party testing reveals significant variation among suppliers:

| Vendor | Deflection Limit | Coating Durability | Lead Time |

|---|---|---|---|

| Supplier A | L/240 | 25 years | 6 weeks |

| Supplier B | L/180 | 15 years | 3 weeks |

Tailored Solutions for Complex Layouts

Modern expanded metal floor grating systems accommodate:

- Non-standard angles (1° increments from 15° to 60°)

- Composite constructions with GFRP reinforcements

- Anti-microbial surface treatments for food facilities

Precision Installation Protocols

Field measurements confirm proper implementation reduces maintenance costs by 33%:

- 0.25" maximum gap between supports

- 70 ft-lb torque specification for fasteners

- ASTM F2413-18 slip resistance compliance

Verified Performance Across Sectors

Documented results from recent installations:

| Application | Grating Type | Service Life |

|---|---|---|

| Chemical Plant Walkways | Hot-Dip Galvanized | 18+ years |

| Airport Loading Bridges | Aluminum Tread | 12 years |

Sustainable Evolution of Flooring Systems

Emerging floor metal grating technologies focus on circular economy principles, with 92% recyclability rates and 30% reduced embodied carbon in next-generation alloys. Recent ISO 14040 audits confirm 18% lower lifecycle environmental impact compared to 2020 industry benchmarks.

(floor metal grating)

FAQS on floor metal grating

Q: What are the common materials used for metal floor grating?

A: Metal floor grating is typically made from steel, aluminum, or stainless steel. These materials offer durability, corrosion resistance, and high load-bearing capacity. Aluminum is preferred for lightweight applications, while steel is ideal for heavy-duty environments.

Q: Where is expanded metal floor grating commonly installed?

A: Expanded metal floor grating is often used in industrial settings, walkways, and platforms. Its slip-resistant surface makes it suitable for areas with heavy foot traffic or machinery. It also provides ventilation and drainage in outdoor or wet environments.

Q: What are the benefits of using floor metal grating over solid flooring?

A: Floor metal grating allows airflow, light penetration, and debris drainage, reducing slip hazards. It is lighter than solid metal plates while maintaining strength. Additionally, it requires less maintenance due to its resistance to rust and wear.

Q: How is metal floor grating secured in place during installation?

A: Metal floor grating is usually fastened using clips, bolts, or welded connections. The method depends on the structure and load requirements. Proper alignment and spacing ensure stability and safety.

Q: Can expanded metal floor grating be customized for specific projects?

A: Yes, expanded metal floor grating can be tailored in thickness, hole patterns, and dimensions. Coatings like galvanization or powder coating are added for enhanced corrosion resistance. Custom designs accommodate unique architectural or industrial needs.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025