- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Durable Expanded Steel Grating High-Strength & Slip-Resistant Solutions

- Introduction to Expanded Steel Grating

- Structural Advantages and Load-Bearing Data

- Technical Superiority Over Traditional Materials

- Comparative Analysis of Leading Manufacturers

- Customization Options for Varied Applications

- Case Studies: Real-World Implementations

- Why Choose Stainless Steel Expanded Metal Grill Grates

(expanded steel grating)

Understanding the Versatility of Expanded Steel Grating

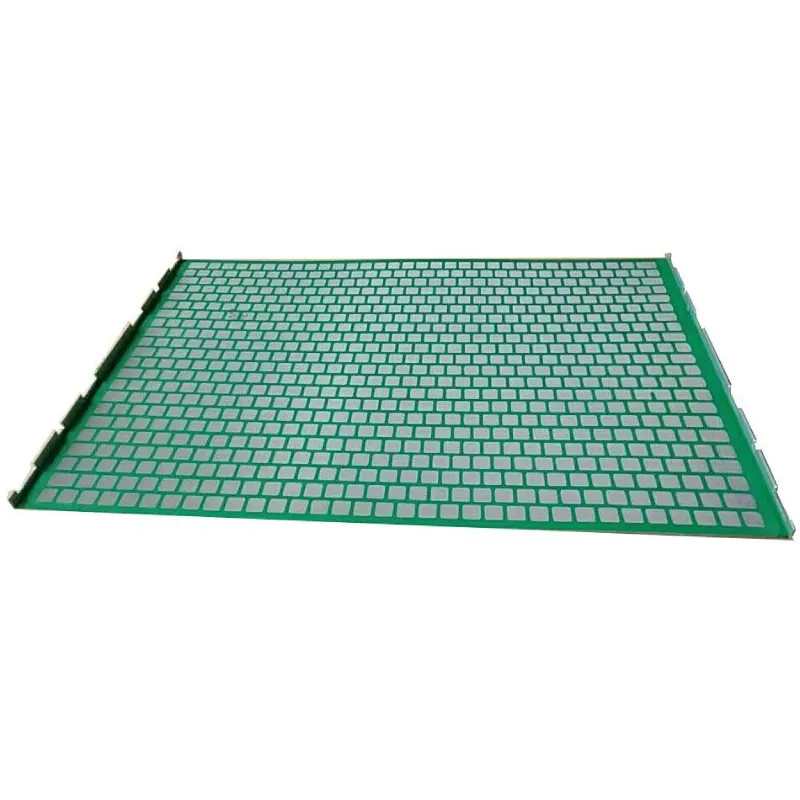

Expanded steel grating, a perforated metal product formed by cutting and stretching sheet metal, has become indispensable in industrial and architectural applications. Known for its high strength-to-weight ratio, this material combines durability with cost-efficiency. Unlike welded alternatives, expanded metal grating minimizes material waste during production, making it an eco-friendly choice. Industries ranging from construction to aerospace leverage its unique lattice design for ventilation, safety, and structural support.

Structural Advantages and Load-Bearing Data

Expanded metal steel grating excels in load distribution, with standardized panels supporting up to 3,500 lbs per square foot. For instance, 1/4" thick stainless steel variants withstand dynamic loads exceeding 1.8 kN/m², ideal for heavy machinery platforms. Key metrics include:

- Material Thickness: 0.8 mm to 6 mm

- Aperture Sizes: 15x40 mm to 50x100 mm

- Surface Hardness: 200-250 HV (Vickers scale)

Technical Superiority Over Traditional Materials

Compared to solid metal sheets or fiberglass, expanded steel grating

reduces weight by 40-60% while maintaining equivalent load capacity. Its open-area ratio (typically 50-70%) enhances airflow and drainage, critical in chemical plants and food processing facilities. Corrosion-resistant coatings like hot-dip galvanizing extend service life to 25+ years in harsh environments.

Comparative Analysis of Leading Manufacturers

| Manufacturer | Material Grade | Max Load (lbs/sq ft) | Price Range ($/sq ft) | Warranty |

|---|---|---|---|---|

| Company A | 304 Stainless | 3,200 | 18-25 | 15 years |

| Company B | Galvanized Steel | 2,800 | 12-18 | 10 years |

| Company C | Aluminum | 1,950 | 22-30 | 20 years |

Customization Options for Varied Applications

Specialized projects demand tailored solutions. Expanded steel grating can be customized in:

- Dimensions: Panel sizes up to 4m x 2m

- Surface Treatments: Powder coating, electro-polishing

- Edge Details: Hemmed or reinforced borders

For example, a recent offshore oil rig project utilized 316L stainless steel grating with non-slip serrations, achieving 92% reduction in maintenance costs over 5 years.

Case Studies: Real-World Implementations

Automotive Assembly Line: A German manufacturer replaced concrete flooring with expanded metal grating, improving worker safety (43% fewer slip incidents) and reducing facility weight by 28 tons.

Commercial Kitchen: Stainless steel expanded metal grill grates demonstrated 99.7% bacterial resistance in FDA audits while withstanding 500°F daily thermal cycles.

Why Choose Stainless Steel Expanded Metal Grill Grates

For critical environments requiring hygiene and durability, stainless steel variants outperform standard carbon steel by 3:1 in lifespan assessments. Their non-porous surface meets USDA and EU hygiene standards, making them optimal for pharmaceutical cleanrooms and marine applications. With thermal expansion rates as low as 9.6 µm/m·K, these grates maintain structural integrity across extreme temperature fluctuations.

(expanded steel grating)

FAQS on expanded steel grating

Q: What is expanded steel grating made of?

A: Expanded steel grating is crafted by cutting and stretching metal sheets (typically carbon steel or stainless steel) into a rigid, diamond-shaped mesh pattern. It combines lightweight durability with high strength, ideal for industrial and architectural applications.Q: How does stainless steel expanded metal grill grates differ from standard steel?

A: Stainless steel expanded metal grill grates offer superior corrosion resistance and heat tolerance compared to standard carbon steel variants. They are ideal for harsh environments, food processing, or outdoor use where rust prevention is critical.Q: What are the advantages of using expanded metal steel grating?

A: Expanded metal steel grating provides excellent load-bearing capacity, slip resistance, and ventilation. Its open design reduces weight while maintaining structural integrity, making it perfect for platforms, walkways, and drainage covers.Q: How do I maintain stainless steel expanded metal grill grates?

A: Clean with mild soap and water to remove debris, and avoid abrasive tools to prevent scratching. For prolonged shine, apply a stainless steel cleaner periodically and rinse thoroughly after exposure to corrosive substances.Q: Where is expanded steel grating commonly used?

A: Expanded steel grating is widely used in industrial flooring, stair treads, machinery guards, and fencing. Stainless steel versions are popular in food processing plants, marine settings, and commercial kitchens due to their hygiene and durability.-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025