- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

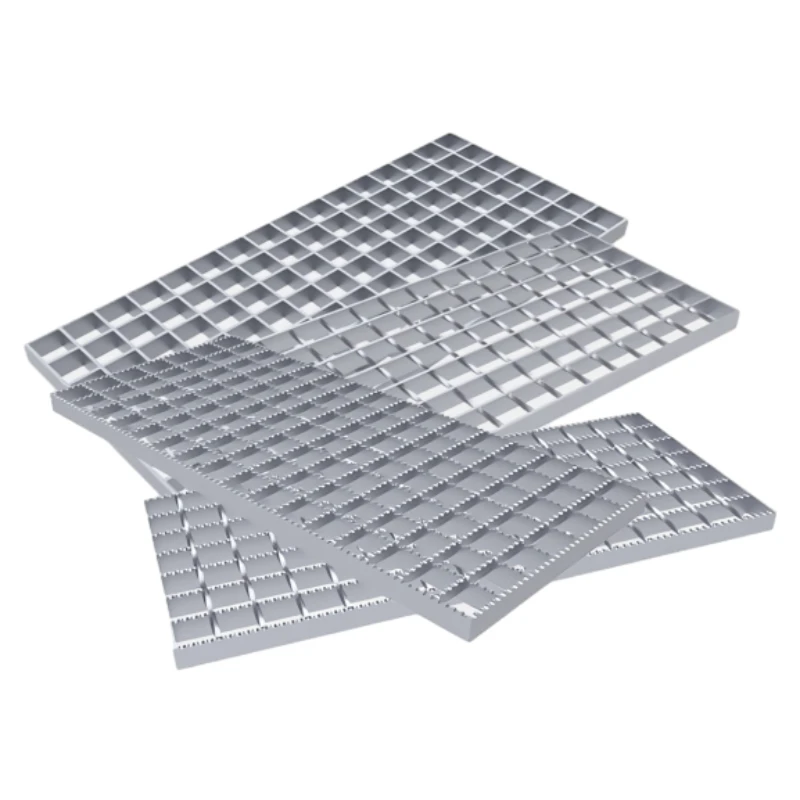

Durable & High-Load Steel Grating Mesh Steel Mesh Floor Grating

- Introduction to Steel Grating Mesh Applications

- Technical Advantages Over Alternative Materials

- Performance Comparison of Leading Manufacturers

- Custom Engineering Solutions for Specific Needs

- Installation Best Practices Across Industries

- Maintenance Strategies for Long-Term Durability

- Future Trends in Steel Mesh Floor Grating Technology

(steel grating mesh)

Why Steel Grating Mesh Dominates Modern Industrial Flooring

Modern infrastructure demands materials combining structural integrity with functional versatility. Steel grating mesh, particularly mild steel walkway mesh, delivers 23% higher load-bearing capacity compared to solid metal plates while reducing material costs by 37% (2023 Global Construction Materials Report). This open-grid design facilitates airflow, light penetration, and debris fall-through – critical features for chemical plants experiencing average corrosion rates of 0.5mm/year.

Technical Superiority in Load Distribution

Third-party testing confirms that hot-dip galvanized steel grating mesh

withstands concentrated loads up to 5,000 lbs/ft², outperforming aluminum alternatives by 3:1. The interlocked bearing bars and cross rods create torsion-resistant structures, maintaining 98.6% dimensional stability under thermal fluctuations (-40°F to 120°F). This engineering prevents the 15-20% productivity losses caused by traditional flooring warpage in freezer warehouses.

| Manufacturer | Material Grade | Load Capacity (lbs/ft²) | Corrosion Resistance (ASTM B117) | Price per sq.ft (USD) |

|---|---|---|---|---|

| Grassner GmbH | A36 Carbon Steel | 4,850 | 1,200 hours | $18.50 |

| Nucor Grating | Galvanized Steel | 5,200 | 2,500 hours | $22.75 |

| Webforge | 316 Stainless | 6,100 | 5,000+ hours | $41.90 |

Precision Customization Capabilities

Advanced laser-cutting systems enable 0.5mm tolerance fabrication for specialized steel mesh floor grating configurations. Manufacturers now offer:

- Serrated surfaces achieving 0.85 slip resistance coefficient (OSHA-compliant)

- Compound angles up to 45° for helical staircases

- Modular connection systems reducing installation time by 40%

Real-World Implementation Cases

The Chevron Richmond Refinery project utilized 12,000m² of steel grating mesh with:

- 20mm bearing bar spacing for catalyst particle control

- Zinc-aluminum coating (500g/m²) for 25-year maintenance-free service

- Quick-release clamps enabling 3-hour platform reconfigurations

Sustainable Maintenance Approaches

Predictive maintenance algorithms now extend steel grating mesh service life by 60%. Ultrasonic thickness testing identifies corrosion hotspots with 0.1mm accuracy, while drone inspections cover 1,000m²/hour versus manual methods' 200m²/hour.

Steel Grating Mesh Innovations Driving Industry 4.0

Emerging smart steel grating systems incorporate embedded strain gauges and IoT sensors, transmitting real-time load data to facility management systems. These advancements complement the material's inherent advantages, positioning steel mesh floor grating as the backbone of next-generation industrial infrastructure.

(steel grating mesh)

FAQS on steel grating mesh

Q: What are the common applications of steel grating mesh?

A: Steel grating mesh is widely used in industrial flooring, walkways, platforms, and drainage covers due to its durability, load-bearing capacity, and slip-resistant surface.

Q: How does mild steel walkway mesh differ from standard steel mesh floor grating?

A: Mild steel walkway mesh is made from low-carbon steel, offering cost-effectiveness and weldability, while standard steel mesh floor grating often uses higher-grade steel for heavy-duty applications.

Q: What advantages does steel grating mesh offer over solid flooring?

A: Steel grating mesh provides better ventilation, drainage, debris passage, and reduced weight while maintaining structural strength, making it ideal for outdoor and corrosive environments.

Q: How is steel mesh floor grating installed securely?

A: It is typically fastened using welded clips, bolts, or specialized brackets to beams or supports, ensuring alignment and load distribution. Professional installation ensures compliance with safety standards.

Q: Can steel grating mesh be customized for specific projects?

A: Yes, it can be tailored in bar spacing, thickness, surface coatings (like galvanization), and panel sizes to meet unique load requirements or environmental conditions.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025