- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Steel Walkway Grating – Anti-Slip, Heavy-Duty, Galvanized

If you build or maintain industrial platforms for a living, you’ve almost certainly wrestled with the question of what to put underfoot. For many of us, the answer is steel walkway grating—especially in oil and gas, power, and water treatment. The industry mood right now? Pragmatic. Safer, faster-to-install panels; tighter QC; still cost-sensitive. And, to be honest, a lot of sites are upgrading after discovering how quickly painted mild steel corrodes in coastal and chemical atmospheres.

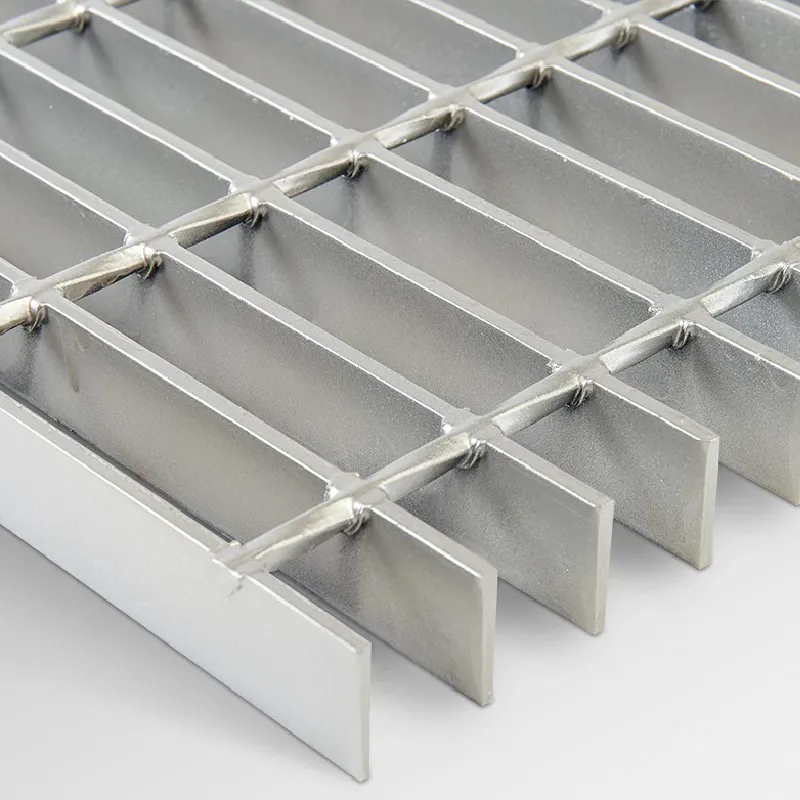

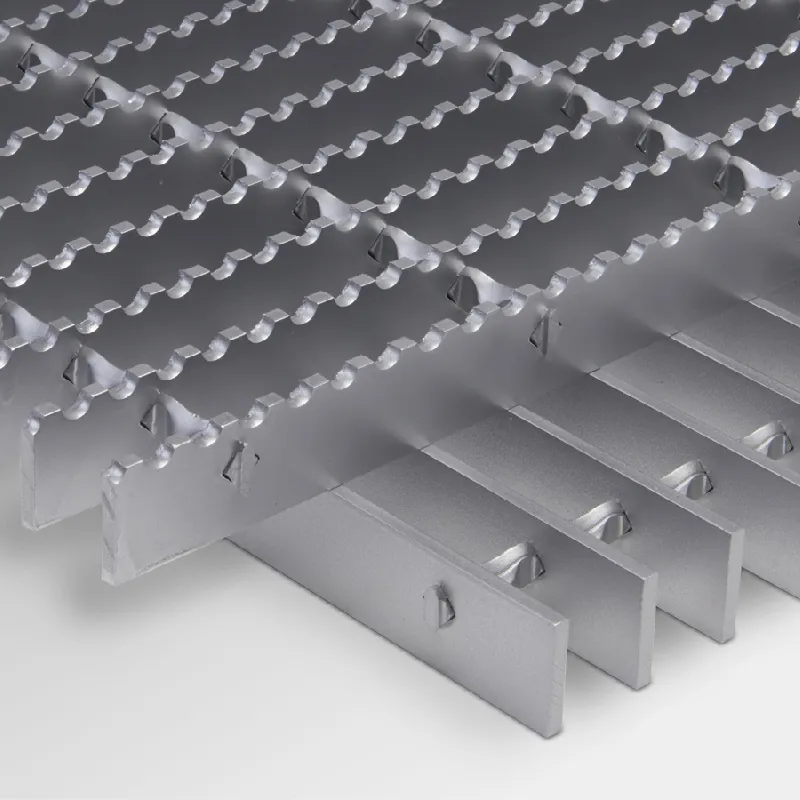

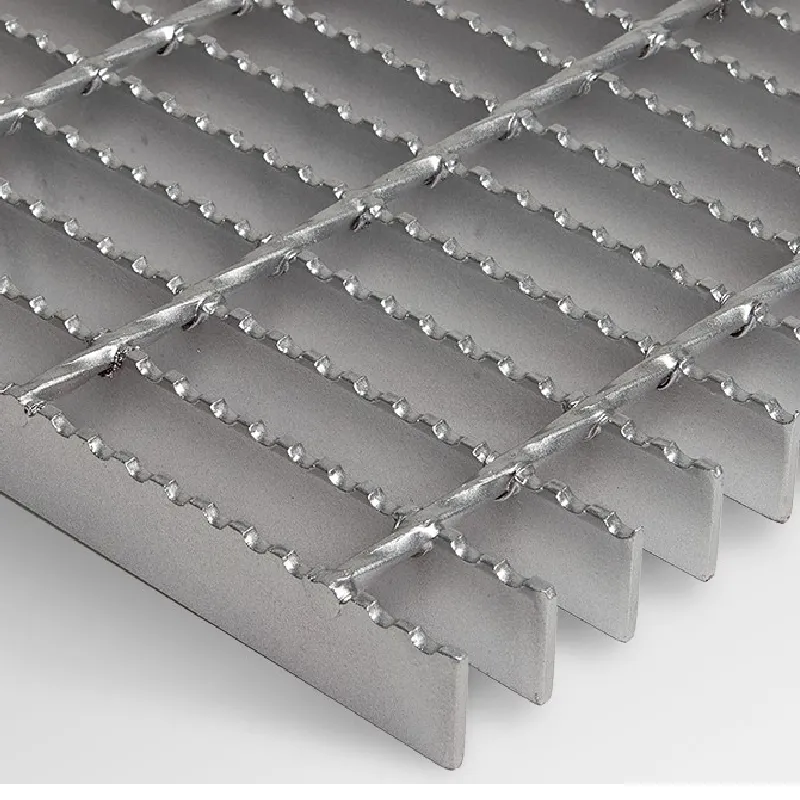

H&F Petro Mesh manufactures in the Industrial zone, South of Anping Town, Hengshui, Hebei, China—basically the nerve center of metal mesh in North China. Their flagship “Steel Grating” line spans welded, press-locked, swage-locked, and riveted patterns. In the field, crews tell me the welded type is the workhorse, while press-locked looks cleaner for architectural catwalks. Either way, steel walkway grating remains the anti-slip platform standard in the petroleum sector.

Quick spec snapshot

| Type | Bearing Bar (typ.) | Pitch | Surface | Coating | Load (≈) |

|---|---|---|---|---|---|

| Welded | 25×3 to 50×5 mm | 30/100 mm, 40/100 mm | Serrated / Plain | HDG per ASTM A123 / ISO 1461 | Span 1 m: ≈4–12 kN/m² |

| Press-locked | 20×3 to 40×5 mm | 30/30 mm, 33/33 mm | Serrated / Plain | HDG or powder (indoor) | Span 1 m: ≈3–8 kN/m² |

| Swage-locked | 25×3 to 32×5 mm | 30/100 mm | Serrated preferred | HDG | Span 1 m: ≈5–10 kN/m² |

Real-world use may vary with steel grade (ASTM A36/A1011 or EN 10025 S235/S275), span, and load direction.

Process flow and quality gates

- Materials: certified coils/flat bars (mill test certificates, heat numbers kept).

- Methods: resistance welding or press/swage interlock; edge banding; toe plates; saddle clips.

- Coating: hot-dip galvanizing to ASTM A123 / EN ISO 1461; typical zinc ≥85 μm for C3–C4 zones.

- Testing: load/deflection checks (BS 4592-0), slip resistance (BS 7976 wet CoF ≈0.6+), visual/galv thickness.

- Service life: around 15–30 years outdoors, longer inland; see ISO 12944 environment class notes.

- Certifications: ISO 9001 QMS; optional third-party inspection (SGS/BV). Compliance with OSHA 1910.22.

Where it’s used (and why)

Oil and gas decks, chemical plants, utility catwalks, mining conveyors, wastewater plants, shipyards—even food processing mezzanines (with tighter pitch). The big wins with steel walkway grating? Strength-to-weight, drainage, debris shedding, and fast bolt-down maintenance. Many customers say serrated bars cut slip incidents, especially when things get… well, greasy.

Vendor comparison (field-notes style)

| Vendor profile | Lead time | Certs/Standards | Customization | Cost level |

|---|---|---|---|---|

| Mill-direct (Anping, China) | ≈10–20 days + transit | ISO 9001, ASTM A123, BS 4592 | High (odd spans, toe plates, clips) | $ (competitive) |

| Regional fabricator (US/EU) | ≈2–4 weeks | Local codes, CE marking where applicable | Medium–High | $$–$$$ |

| Trading/OEM house | Varies | Mixed; check MTCs | Medium | $–$$ |

Customization and real project notes

Cut-to-size panels with banding, kick plates, and galvanized clamps save night-shift hours—no sparks near hydrocarbons, thank you. Recently, an offshore refit in Bohai Bay swapped corroded plank for serrated steel walkway grating; site safety logs showed fewer slips in the first wet season. Another job, a Texas food plant, chose press-locked with 33/33 pitch to keep small tools from dropping—maintenance loved it.

What to check before you buy

- Span and design load per BS 4592 or local code; ask for deflection data.

- Galvanizing thickness report (aim ≥70–85 μm for C3/C4) and drain-hole quality.

- Slip test claim (target wet CoF ≈0.6+); serrations aligned with traffic.

- Marking and traceability: heat numbers on bundles, drawings with panel maps.

Customer feedback is consistent: “deliver panels labeled to the platform grid and you save us a day.” It seems simple, but on shutdowns, that’s gold.

Standards mentioned

OSHA 1910.22 (walking-working surfaces), BS 4592 (industrial flooring), EN ISO 14122 (safety of machinery—walkways), ASTM A123 / EN ISO 1461 (HDG), BS 7976 (pendulum slip), ISO 12944 (corrosion).

- OSHA 1910.22 Walking-Working Surfaces. https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.22

- BS 4592 Industrial type flooring and stair treads. https://shop.bsigroup.com

- ASTM A123/A123M Zinc (Hot-Dip Galvanized) Coatings. https://www.astm.org/a0123_a0123m-17.html

- EN ISO 1461 Hot dip galvanized coatings. https://www.iso.org/standard/59049.html

- BS 7976 Pendulum test for slip resistance. https://www.bsigroup.com

- ISO 12944 Corrosion protection of steel structures. https://www.iso.org/standard/79010.html

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025