- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

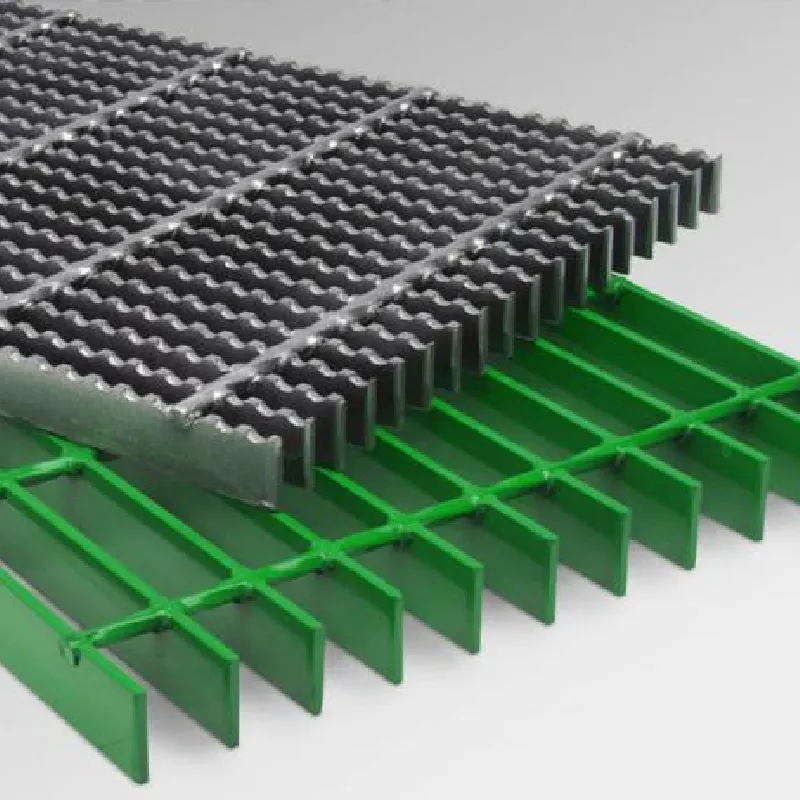

Welded Bar Grating – Heavy-Duty, Anti-Slip, Galvanized

Welded Steel Grating: field notes, specs, and what buyers really ask

If you’re weighing up welded bar grating for walkways, floors, or platforms, you’re not alone. Plants are upgrading for safety and corrosion performance—fast. In fact, many customers say they’re moving away from improvised checker plate to serrated panels for the extra grip. From my trips to Anping (the industrial zone south of Anping Town, Hengshui, Hebei, China—yes, the world’s wire/mesh hub), the trend is clear: better slip resistance, smarter coatings, and tighter QA.

Product snapshot: Welded Steel Grating

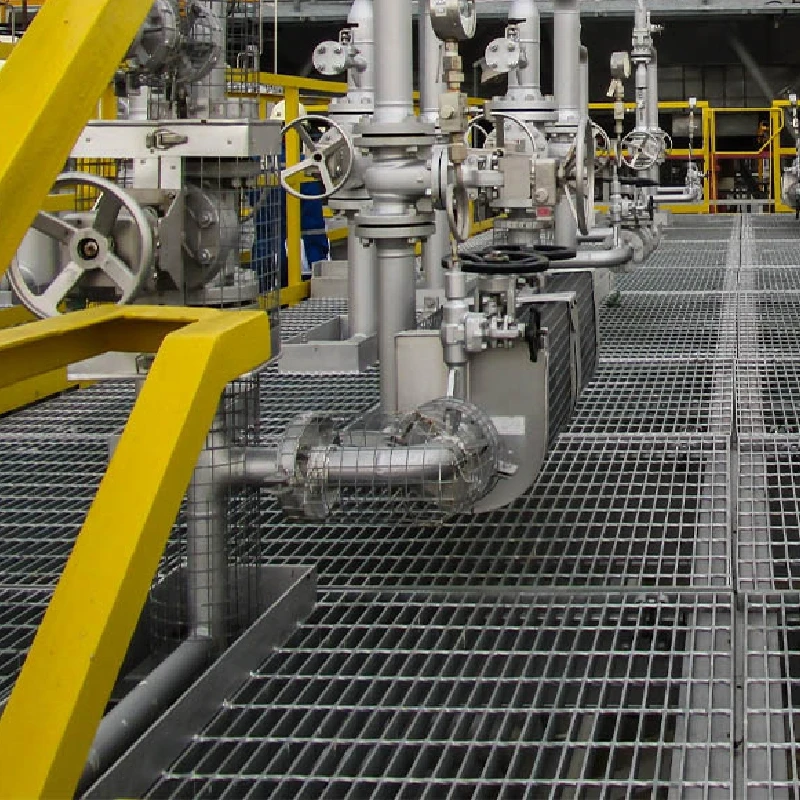

The core of welded bar grating is simple: bearing bars press-welded to cross rods, then finished (often hot-dip galvanized) for long service. It’s the go-to for stair treads, catwalks, wastewater decks, and petrochemical platforms where drainage and airflow matter.

| Spec | Details (≈ values; real-world use may vary) |

|---|---|

| Materials | Carbon steel ASTM A36 / Q235B; optional SS304/316 for corrosive/food areas |

| Bar type & size | Plain or serrated; 25×3 to 50×5 mm bearing bars (others on request) |

| Spacing | Bearing bar c/c ≈ 30 or 40 mm; cross rod c/c ≈ 100 mm |

| Finish | HDG per ASTM A123 / ISO 1461; zinc thickness ≈ 70–100 μm |

| Slip resistance | Serrated COF dry ≥ 0.75; wet ≥ 0.55 (tested with validated tribometer per ASTM F2508) |

| Load/deflection | Typical L/200 limit; panel loads verified to NAAMM MBG 531 guidance |

| Service life | HDG in C3: ≈ 20–40 yrs; C4: ≈ 10–25 yrs (ISO 14713-1) |

How it’s made (quick process flow)

Steel prep → press-welding/forge welding (AWS D1.1 WPS) → trimming and edge banding → nosing/toe plate (if stair treads) → hot-dip galvanizing → QA: coating thickness (ISO 2178), load checks (NAAMM), visual/fit checks → packing. To be honest, the dull part is the best part: consistent weld current and flatness checks make or break quality.

Where it’s used

Petrochemical racks, power plants, mining conveyors, wastewater treatment walkways, shipbuilding docks, food plants (switch to stainless), and brewery cellars. welded bar grating shines where drainage, ventilation, and easy hose-down are essential.

Advantages customers mention

- High strength-to-weight; long spans reduce supports.

- Anti-slip (serrated) without trapping sludge.

- Low maintenance—galvanizing outlasts paint by years.

- Open area ≈ 70% for airflow and firewater drainage; OSHA-friendly walking-working surfaces.

Customization that matters

Clip sets, saddle clamps, kick plates, checker-plate infill zones, custom shapes (curved/miters), and rapid stair tread kits with abrasive nosing. Lead times are actually solid if drawings are clean.

Vendor comparison (what buyers really compare)

| Criteria | HF Petro Mesh (Anping) | Import Broker | Local Fabricator |

|---|---|---|---|

| Origin | Industrial zone, South of Anping Town, Hebei | Varies | Domestic |

| Lead time | ≈ 10–20 days + transit | ≈ 25–45 days | ≈ 7–15 days |

| Standards | ASTM A36, ASTM A123/ISO 1461, AWS D1.1, NAAMM | Depends | Usually ASTM/AWS |

| Customization | High (CNC cutting, odd shapes) | Medium | High but pricier |

| QC traceability | Heat/lot tracking; coating logs | Limited | Good |

Case notes and feedback

• A Gulf Coast refinery swapped FRP for galvanized welded bar grating on a pump deck; downtime from slip incidents dropped to zero over 18 months (their number, not mine).

• A brewery in Melbourne went with 316 serrated treads; hot caustic washdowns didn’t faze it after a year—only light tea staining near welds.

Final tip: specify bar size/spacing, loading criteria (concentrated vs uniform), finish standard (ASTM A123/ISO 1461), and deflection limit. Add clip type and any toe plates in the RFQ to avoid surprise change orders.

Authoritative references

- NAAMM MBG 531 – Metal Bar Grating Manual.

- ASTM A123/A123M – Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel.

- ISO 1461 / ISO 14713-1 – Hot dip galvanizing and service life guidance.

- AWS D1.1 – Structural Welding Code: Steel.

- OSHA 29 CFR 1910.22 – Walking-Working Surfaces.

- ASTM F2508 – Validation of walkway tribometers; ISO 2178 – Coating thickness (magnetic).

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025