- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Shale Shaker Screen Factory | API 13C, OEM, Fast Delivery

Inside a shale shaker screen factory: composite frames, real testing, and what buyers actually ask

If you’ve ever stood on a rig floor during a sticky OBM run, you know the shaker screens take the heat. In Anping—Hebei’s wire-mesh heartland—I spent a day walking the lines where composite frame screens roll out. Not a museum tour; a working line. Smell of resin, hum of pre-tensioners, and operators who can hear when a mesh bond is right. That’s the difference between marketing copy and parts that last.

What’s trending (and why composite frames won)

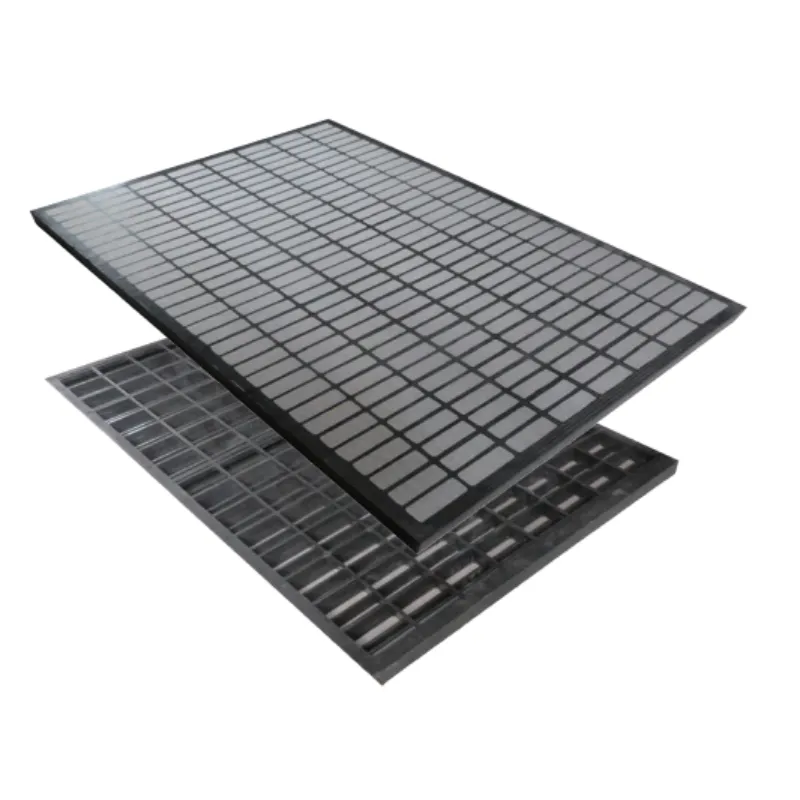

Steel frames are tough, sure, but composites are eating their lunch. They’re lighter, corrosion-proof, and—surprisingly—stiffer where it counts. Many customers say the extra open area and stable mesh tension help them hold cut-points longer between trips. In fact, crews tell me they swap screens faster and carry more spares without breaking backs. The product here is the Composite Frame Shaker Screen, built in the industrial zone south of Anping Town, Hengshui, Hebei, China. A proper shale shaker screen factory vibe—busy, methodical, a bit gritty.

Typical specifications (field-proven, not lab fantasy)

| Parameter | Composite Frame Shaker Screen (≈ values; real-world use may vary) |

| API rating (RP 13C) | API 20–230 typical |

| D100 cut point | ≈ 44–840 μm (per API 13C) |

| Conductance | ≈ 0.7–9.0 kD/mm |

| Open area | up to ≈ 60% |

| Mesh layers | 2–4 (SS304/SS316) |

| Frame material | Glass-fiber reinforced composite, powder-coated inserts |

| Common sizes | ≈ 585×1165 mm, 630×1250 mm; customs on request |

| Temp/chem resistance | up to ≈ 120°C; oil/water-based muds |

| Service life | ≈ 300–700 hours (solids loading dependent) |

How it’s made (short version)

- Materials: SS304/316 multi-layer mesh, glass-fiber composite frame, epoxy bonding, nitrile seals.

- Methods: mesh pre-tensioning → composite molding → epoxy lamination → hot-cure → gasket fitment.

- QC & testing: API RP 13C D100 and conductance; flatness/warp check ≤ 1.5 mm; salt-spray ≈ 72 h; drop tests.

Test data snapshot: an API 170 screen here showed D100 ≈ 82 μm and conductance ≈ 2.2 kD/mm under 5-cm head—solid numbers. To be honest, mud chemistry matters more than brochures admit.

Applications and feedback

Oil & gas drilling, HDD river crossings, mining tailings, geothermal—anywhere solid–liquid separation keeps costs sane. Crews report fewer mid-shift swaps and steadier flow. One driller joked the composite frame “doesn’t rust even when the shaker house leaks,” which, well, happens.

Vendor comparison (quick reality check)

| Criteria | HF Petro Mesh (Anping) | Vendor A (steel-only) | Vendor B (imported) |

| API RP 13C labels | Yes (per batch) | Partial | Yes |

| Weight/handling | Light composite | Heavier steel | Light composite |

| Customization lead time | ≈ 7–15 days | ≈ 20–30 days | ≈ 25–40 days |

| Price trend | Stable | Low upfront | High |

Case notes from the field

- West Texas OBM pad: switching to composite screens trimmed low-gravity solids by ≈ 12–18% and saved about two changeouts per 24 h. NPT due to blinding fell noticeably.

- HDD river crossing (silts): API 140/170 combo held cut-point through a 10-hour continuous pull; dilution dropped ≈ 10 m³/day. Small win, big smiles.

Ordering tips: ask your shale shaker screen factory for API 13C test sheets, open-area maps, and frame resin certificates. Also confirm shaker model fit (Brandt, Derrick, M-I SWACO, FLC styles, etc.) and gasket type. Small specs, big consequences.

Certifications and standards

Factory quality systems audited to ISO 9001:2015, product labeling and testing per API RP 13C. It seems basic, but those two stamps filter out a lot of guesswork.

Customization menu

Private label, color coding, bespoke dimensions, 2–4 layer mesh packs, side or hook-strip styles, anti-blind panels, and crate kits for offshore. Ask the shale shaker screen factory to match your mud program: OBM vs WBM behaves differently on fine meshes.

References

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025