- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Steel Walkway Grating | Anti-Slip, Durable, Easy Install

Field Notes from the Catwalk: Why steel walkway grating still sets the standard in harsh industrial zones

I’ve walked more catwalks than runways (industrial ones, to be clear), and I keep coming back to one simple truth: when crews trust the platform, productivity follows. In the petroleum sector especially, steel walkway grating is still the default. It’s grippy, drains well, shrugs off sparks, and—if you spec it right—lasts ages. The model I’ve been tracking comes out of the industrial zone south of Anping, Hengshui, Hebei, China. I’ve visited that cluster; it’s a hive of welding arcs and zinc kettles, in a good way.

What’s moving the market in 2025

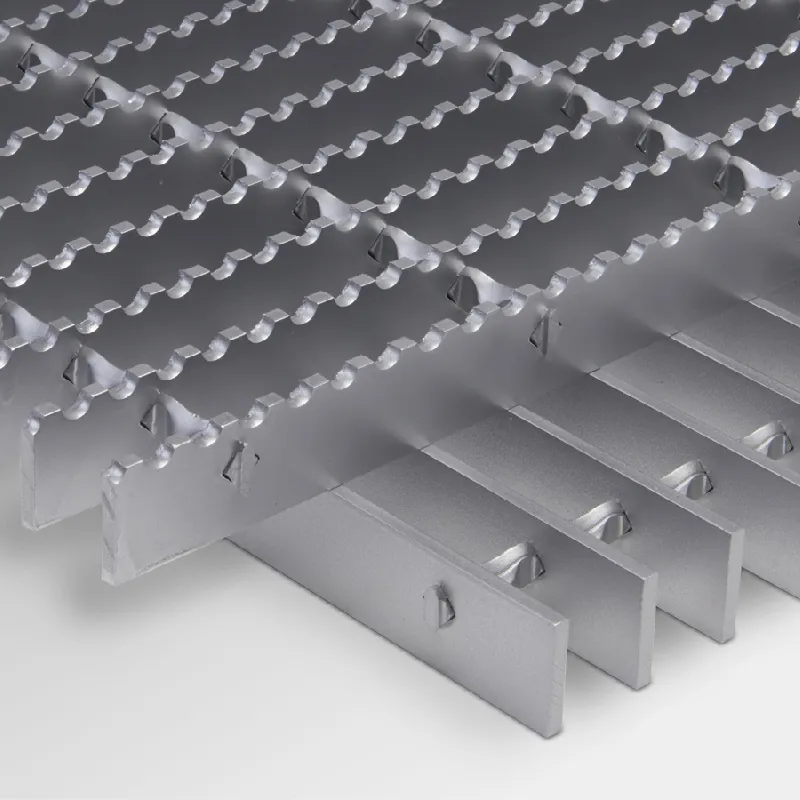

- Safety-first retrofits driven by OSHA/EN rules; serrated bars are now the default in wet zones.

- Hot-dip galvanizing demand up; real-world buyers want 70–100 μm zinc for coastal plants.

- Faster installs via press-locked and swage-locked panels—less spark-work at site.

- Traceability and paperwork (ISO 9001, mill certs) are no longer “nice-to-haves.”

Quick technical overview

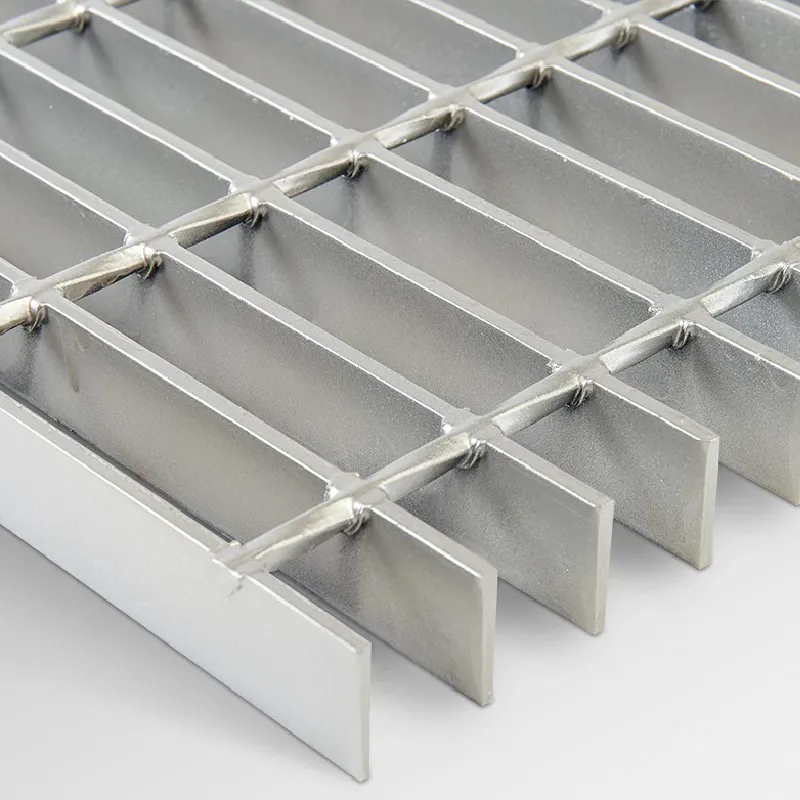

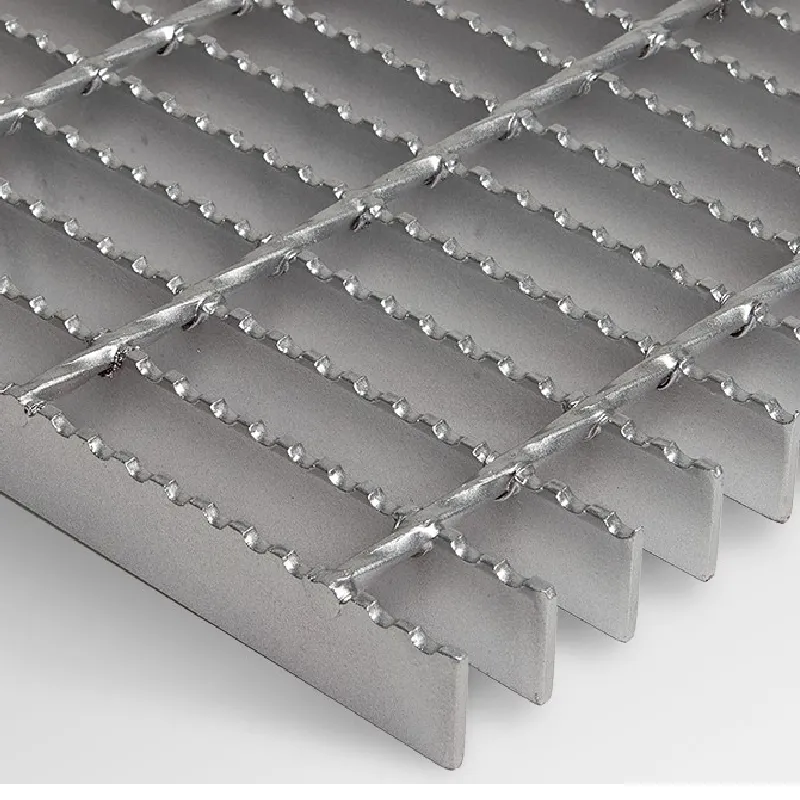

“Steel Grating” here spans welded, press-locked, swage-locked, and riveted designs. Materials usually mean carbon steel (ASTM A36/A1011) or stainless (304/316) if chemicals are gnarly. Finishes: hot-dip galvanized to ASTM A123 / EN ISO 1461, or self-color for indoor dry runs (rare). Serrated load bars for slip resistance. Spans? It depends—always check deflection vs. load tables; no shame in being conservative.

Typical product specs (indicative)

| Load bar size | 25×3 to 50×5 mm (≈1×1/8 to 2×3/16 in) |

| Load bar pitch | 30–40 mm typical |

| Cross bar pitch | 50–100 mm |

| Finish | HDG per ASTM A123 / EN ISO 1461; stainless bare |

| Slip resistance | Serrated bars; CoF wet ≈ 0.55–0.70 (real-world may vary) |

| Deflection criteria | L/200–L/240 common practice |

Process flow and QA (how the good stuff is made)

Material prep with mill-certified flats; welding or mechanical locking; edge banding; cutting to fit; hot-dip galvanizing; final deburr and stamping. Testing? Zinc thickness (mag gauge), load/deflection sampling to BS 4592 methods, visual for weld continuity, and slip checks on serrated sets. Service life: around 20–30 years HDG inland, ≈10–20 years coastal unless you upgrade to stainless or duplex coatings.

Where it gets used (and why)

- Oil & gas platforms, refineries—spark-friendly, drains fast, meets OSHA walking–working surface rules.

- Power and wastewater—corrosion resistance matters; choose heavier zinc or 316.

- Food & beverage catwalks—press-locked for smoother top, easier sanitation.

- Data center rooftops—lightweight spans with toe plates; fewer trip hazards.

Vendor snapshot (what I’ve seen on bids)

| Vendor | Lead time | Galv. standard | Certs | Customization |

|---|---|---|---|---|

| HF PetroMesh (Anping) | 2–4 wks ≈ | ASTM A123 / EN ISO 1461 | ISO 9001, mill certs | High—radiused cuts, toe plates, clips |

| Local fab (generic) | 1–3 wks | Varies; check DFT | Varies | Medium; site fitting |

| Import broker | 4–8 wks | Often compliant | Paperwork sometimes light | Low–medium |

Customization that actually helps installers

Pre-notched panels around pipe racks, clip sets for non-weld installs, serration patterns, checker-plate kick plates, and bund grating with tighter cross-bar pitch. Many customers say pre-fitted toe plates shave hours off shutdown schedules.

Mini case notes

- Offshore platform, South China Sea: switched to serrated HDG 40×5 with 30/100 pitch; slip incidents dropped noticeably within a quarter.

- Craft brewery: press-locked 304 with smooth top; CIP runoff cleared fast, zero rust blooms after 18 months.

- Wastewater headworks: A36 HDG with extra zinc (≈100 μm). Inspector happy; deflection within L/240 on 900 mm span.

Compliance, testing, paperwork

Look for ISO 9001 QA, coating certs to ASTM A123 or EN ISO 1461, load checks against BS 4592, and site conformity to OSHA 1910 (handrails, toe boards, clear widths). To be honest, the documentation trail is often what separates smooth handover from punch-list purgatory.

References

- OSHA 29 CFR 1910 Walking-Working Surfaces: https://www.osha.gov/laws-regs/regulations/standardnumber/1910

- ASTM A123/A123M – Hot-Dip Zinc Coatings: https://www.astm.org/a0123_a0123m.html

- EN ISO 1461 – Hot dip galvanized coatings: https://www.iso.org/standard/69886.html

- BS 4592 Metal open bar gratings: https://shop.bsigroup.com/ (search BS 4592)

- ISO 9001 Quality management systems: https://www.iso.org/iso-9001-quality-management.html

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025