- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

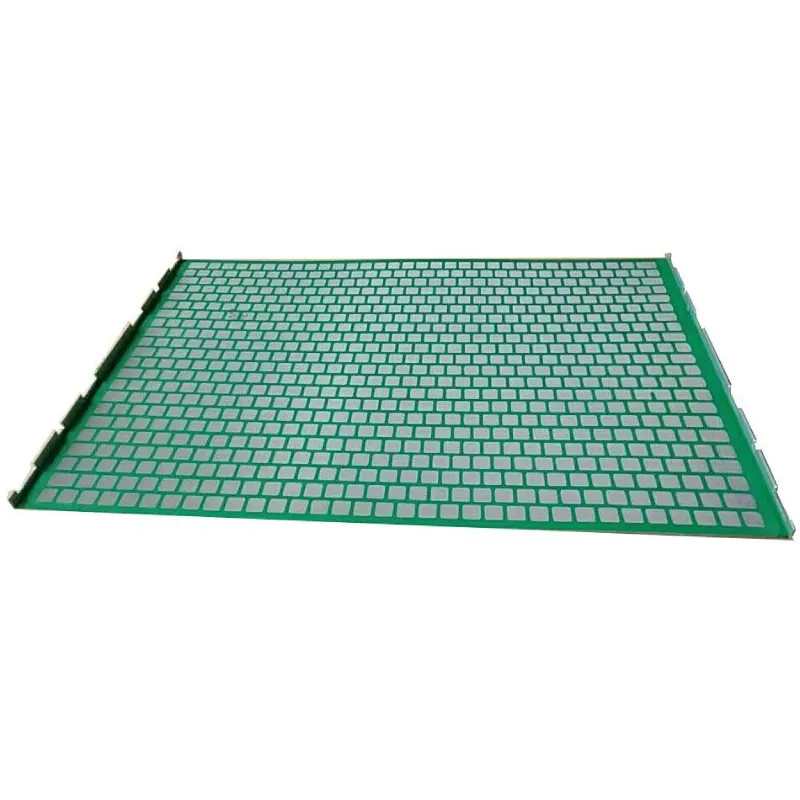

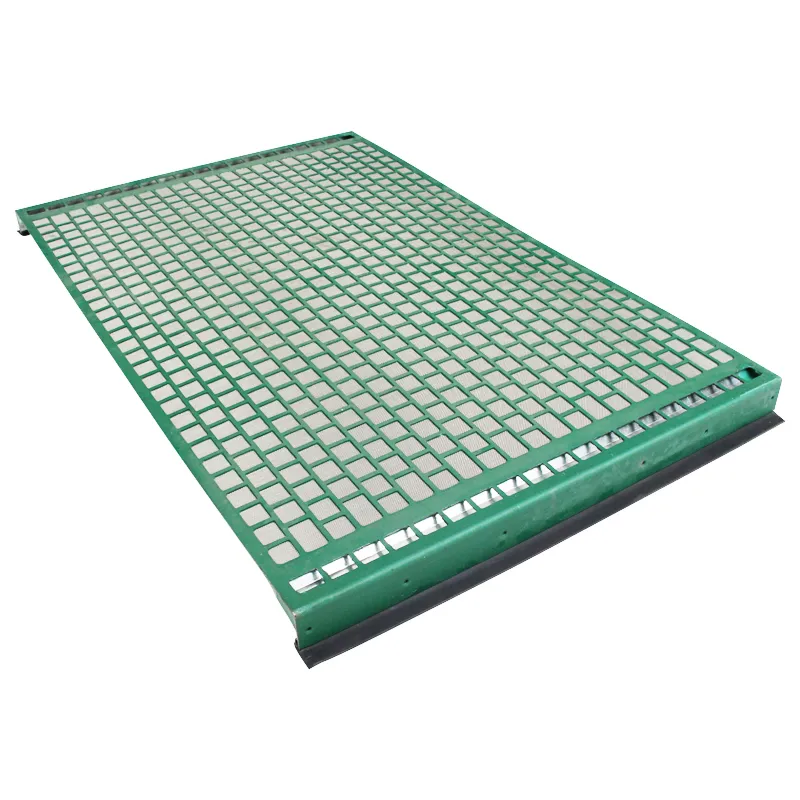

Shale Shaker Screen – Durable, High-Efficiency, Best Price

Hook Strip Flat Screen: A Field Insider’s Take

If you’ve ever stood next to a roaring shaker house at 2 a.m., you already know the hero of solids control is the humble shale shaker screen. The Hook Strip Flat Screen from Anping—yes, that famous wire-mesh industrial zone south of the town in Hengshui, Hebei—has been a reliable workhorse. It’s known for good filter accuracy, and it’s widely used in waste management and drilling fluids control. To be honest, the demand curve is bending toward tighter cuts with longer service life, and this design still holds its own.

Industry trends (and a quick reality check)

Actually, operators want finer API ratings without skyrocketing costs. Composite frames are popular, but many customers say the hook-strip format still wins when you need simple logistics, easy hook-in, and predictable tension. Environmental compliance is pushing better solids removal, and that’s nudging screens toward API 100–140 in many plays. It seems that tighter screens plus smarter mud programs are paying back in fluid recovery.

Technical snapshot

- Product: Hook Strip Flat Screen (strong on filter accuracy)

- Origin: Industrial zone, South of Anping Town, Hengshui, Hebei, China

- Use cases: drilling fluids control, waste management, HDD, mining slurries

- Standards: API RP 13C testing; ISO 9001-based QC; abrasion checks per ASTM guidance

| Spec | Typical Value (≈, real-world use may vary) |

|---|---|

| Mesh/API range | API 20–325 |

| D100 cut point | ≈ 75–850 μm (per API RP 13C) |

| Conductance | ≈ 0.6–2.5 kD/mm (lab tested) |

| Open (non-blanked) area | around 36–45% |

| Material | SS304/SS316 wire cloth; steel hook strips |

| Layers | 2–4 layers, pre-tensioned |

| Gasket/Seal | EPDM/NBR as specified |

| Service life | ≈ 120–300 hours typical (solids load dependent) |

How it’s built (short version)

Materials: SS304/316 mesh, steel hook strips, epoxy bonding, rubber gasket. Methods: pre-tensioning, multi-layer lamination, precise bonding, flatness check. Testing: API RP 13C for D100/Conductance, visual/mesh count checks, vibration fatigue runs, abrasion spot checks (ASTM G65 style). I guess the key is consistent tension—many failures trace back to that.

Where it works best

- Oil & gas rigs: primary and secondary shakers using shale shaker screen panels in API 60–140. - Waste pits/mud plants: reclaim barite, reduce haul-off. - HDD and mining: when fluids costs matter, shale shaker screen efficiency does too.

Customization

Panel sizes, hook types, mesh layering, and gasket options can be tailored. Many customers say custom cut-points (e.g., API 100 with higher conductance) delivered noticeable fluid recovery gains.

Vendor comparison (quick buyer’s table)

| Item | HF Petromesh (Anping) | Vendor A (Importer) | Vendor B (Local Fab) |

|---|---|---|---|

| API RP 13C report | Yes, available | Sometimes (on request) | Rare |

| Lead time | ≈ 7–15 days | Stock-dependent | ≈ 3–10 days |

| Customization | High | Medium | Low–Medium |

| Price level | Mid, value-focused | High | Low |

Case notes from the field

Permian Basin, onshore: swapping to API 100 shale shaker screen (conductance ≈ 1.2 kD/mm, non-blanked area ≈ 41%) delivered roughly +12% fluid recovery and about +30% screen life compared with the previous generic panel—per customer logs. Offshore Southeast Asia: API 140 shale shaker screen reduced ultrafines carryover enough to lower dilution rates by ≈ 8–10%. Not every rig will see that, but you get the idea.

Why teams choose it

- Predictable API cut points and decent conductance. - Straightforward installation; easy to stock and ship. - Solid QC trail (API RP 13C reports, ISO 9001 plant-level processes). In fact, the consistent pre-tension often matters more than fancy buzzwords.

Certifications & references

API RP 13C-compliant testing; ISO 9001 for quality management. Abrasion and vibration routines documented in factory reports; full data sheets on request.

- API RP 13C – Drilling Fluids Processing Systems Evaluation (API). https://www.api.org/

- ISO 9001:2015 – Quality management systems (ISO). https://www.iso.org/standard/62085.html

- ASTM G65 – Standard Test Method for Measuring Abrasion. https://www.astm.org/Standards/G65

- OnePetro Technical Library (SPE/IADC papers on solids control). https://onepetro.org/

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025