- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

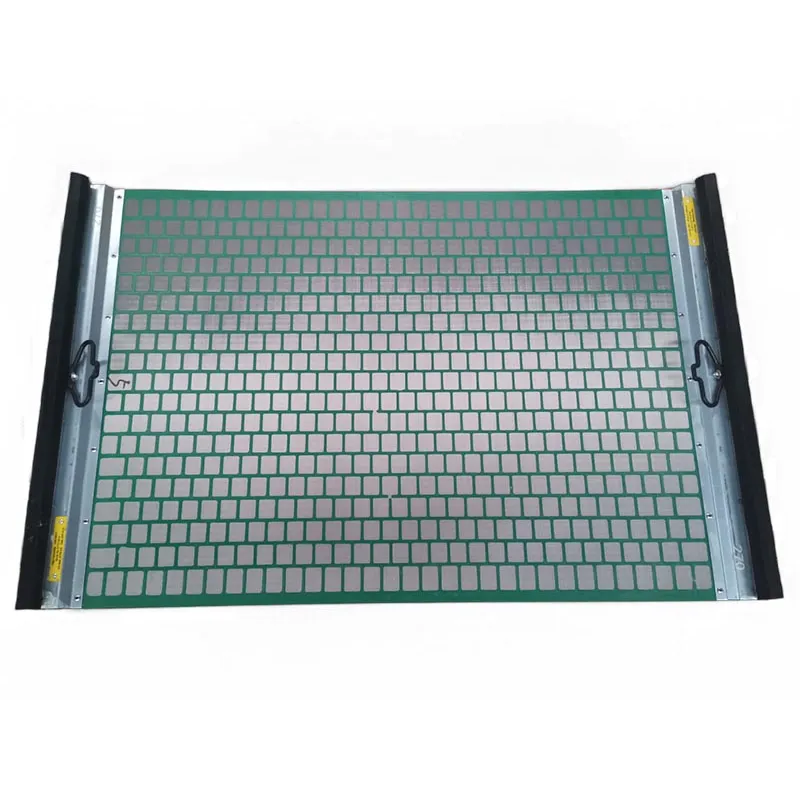

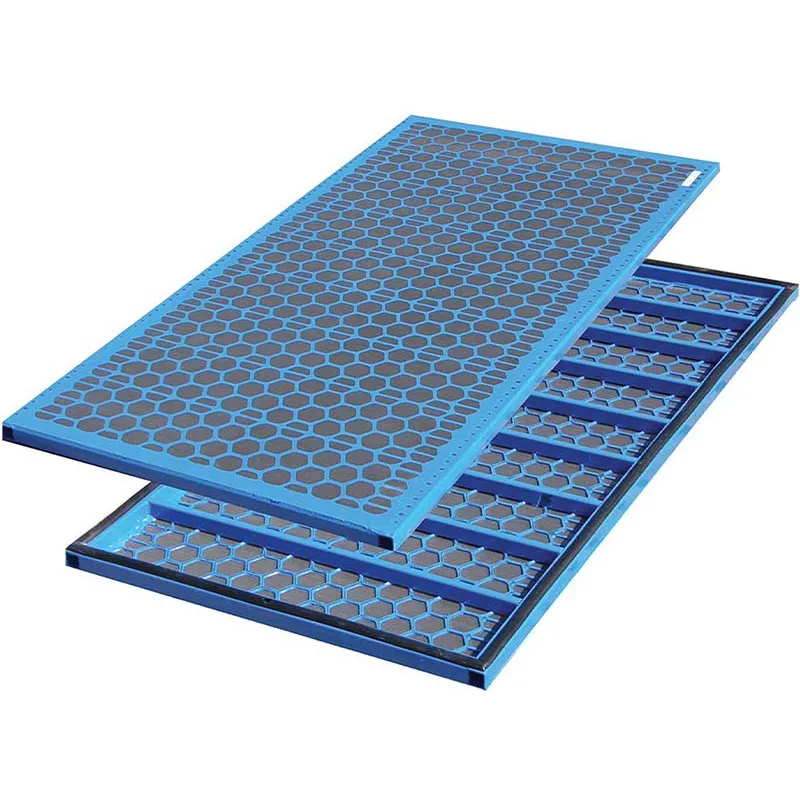

Shale Shaker Screen | High-Efficiency, Durable, OEM Supply

Field Notes on the Modern shale shaker screen

I’ve been in enough mud rooms to know: when solids control drifts, costs spike. The humble shale shaker screen is where efficiency begins, and sometimes dies. Lately, operators tell me they’re pushing higher flow with slimmer margins—so screen selection, testing, and vendor reliability matter more than ever.

What’s new on the rig deck

Trends? To be honest, it’s a split: big fleets are standardizing on API RP 13C-compliant screens with tighter D100 control, while independents chase cost-per-hour. Multi-layer stainless meshes (304/316) and composite frames are now the practical default. Plus, faster swaps and fewer leaks—small wins that add up in a 24/7 operation.

Quick spec snapshot (real-world use may vary)

| Mesh/Grade | API 20–API 325 (≈ 840 μm to 44 μm D100) |

| Wire Material | SS304 / SS316 (tri-layer options) |

| Frame Type | Composite or steel; hook-strip & pretensioned panel |

| Typical Sizes | 585×1165 mm, 630×1250 mm, 700×1050 mm (custom on request) |

| Bonding | Epoxy/polymer; corrosion-resistant |

| Conductance | ≈ 0.5–6.0 kD/mm (API 13C test cell) |

| Service Life | around 120–600 drilling hours, depending on flow/solids |

How it’s made (short version)

- Materials: SS304/SS316 wire cloth; composite or steel frames.

- Methods: multi-layer weaving, tensioning, and epoxy bonding; gasket sealing; laser-etched API labels.

- Testing: API RP 13C (D100 cut point, conductance, non-blanked area); salt-spray on coated frames.

- Service life checks: cyclic vibration + flow abrasion tests; random lot inspection per ISO 2859.

- Origin: Industrial zone, South of Anping Town, Hengshui, Hebei, China.

Where it works best

Oil & gas drilling (OBM/WBM), HDD and trenchless, geothermal, mining tailings, and even some wastewater polishing. Many customers say swapping to a finer yet higher-conductance shale shaker screen cut dilution water by 8–12%—not bad.

Vendor comparison (informal, yet practical)

| Vendor | Strengths | Watch-outs |

|---|---|---|

| HF PetroMesh (composite/steel) | API 13C-labeled; steady conductance; custom sizing; MOQ-friendly | Lead time spikes during peak seasons |

| Major OEM | Rig-proven, easy compatibility, global stock | Premium price; limited custom meshes |

| Budget Import | Low upfront cost | Variable D100; gasket leakage; shorter life |

Customization options

- Frames: steel vs. composite; hook-strip vs. pretensioned panels.

- Mesh: 2–3 layers; 304 vs. 316; API 20–325.

- Edge sealing: nitrile, HNBR, or EPDM for hot OBM.

- Color-coded corners; serialized traceability; private label.

Field data and feedback

On a West Texas pad, swapping to API 140 composite shale shaker screen raised conductance ≈18% versus prior steel frames; average life nudged from 210 to 290 hours (similar flow, OBM, high LGS). Crew liked the corner locks—faster changes, fewer pinches.

Compliance and credentials

API RP 13C-labeled, ISO 9001:2015 quality system; batch test summaries available on request. If you’re auditing: look for D100/cell reports, salt-spray hours, and gasket compression set numbers. Small details, big difference.

Authoritative citations

- API RP 13C – Recommended Practice on Shaker Screen Testing and Labeling: https://www.api.org

- ISO 9001:2015 Quality Management Systems (ISO): https://www.iso.org/standard/62085.html

- IADC Drilling Manual – Solids Control Fundamentals (IADC): https://www.iadc.org

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025