- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

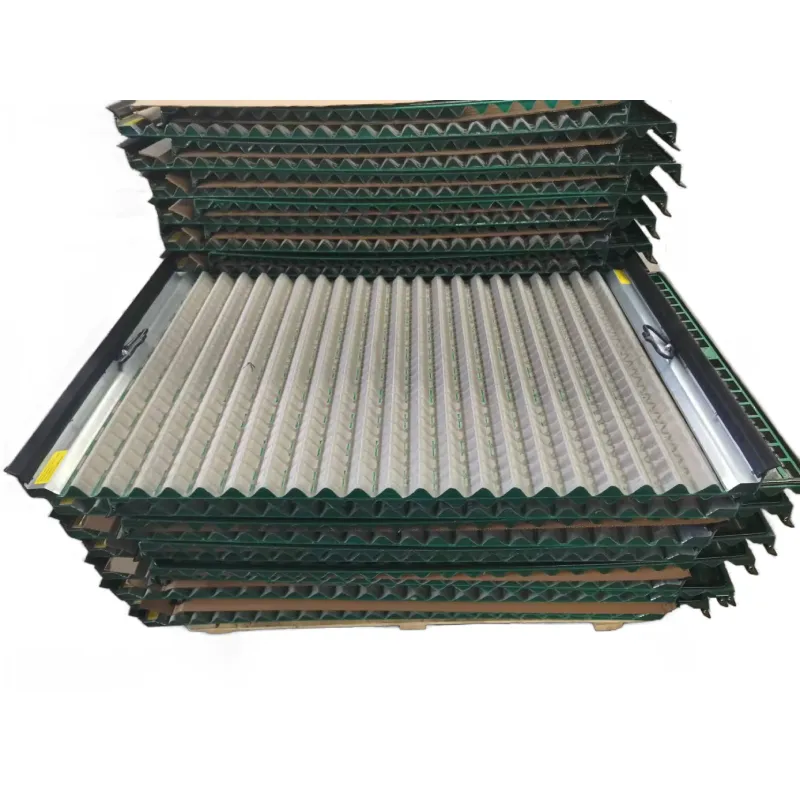

Derrick Pyramid Screens - High Conductance, Long Life

If you spend time around solids control crews (I do, too often, coffee in hand), the talk always turns to screens—what lasts, what plugs, what actually saves mud. It’s why many buyers searching for derrick pyramid screens end up asking about 3D wave-style alternatives. The 3D Shaker Screen from HF PetroMesh—built in the industrial zone, south of Anping Town, Hengshui, Hebei, China—has been making the rounds lately, and for good reasons I’ll get into.

Industry trends (short version)

Rigs are drilling faster; mud costs are under a microscope. The swing has been toward higher API designations, composite frames, and—yes—3D corrugated profiles that increase non-blanked area. In practice, derrick pyramid screens-style geometry helps keep conductance up as the mesh gets finer, without torpedoing service life. Operators tell me they want fewer screen swaps and more consistent cut points. Same here.

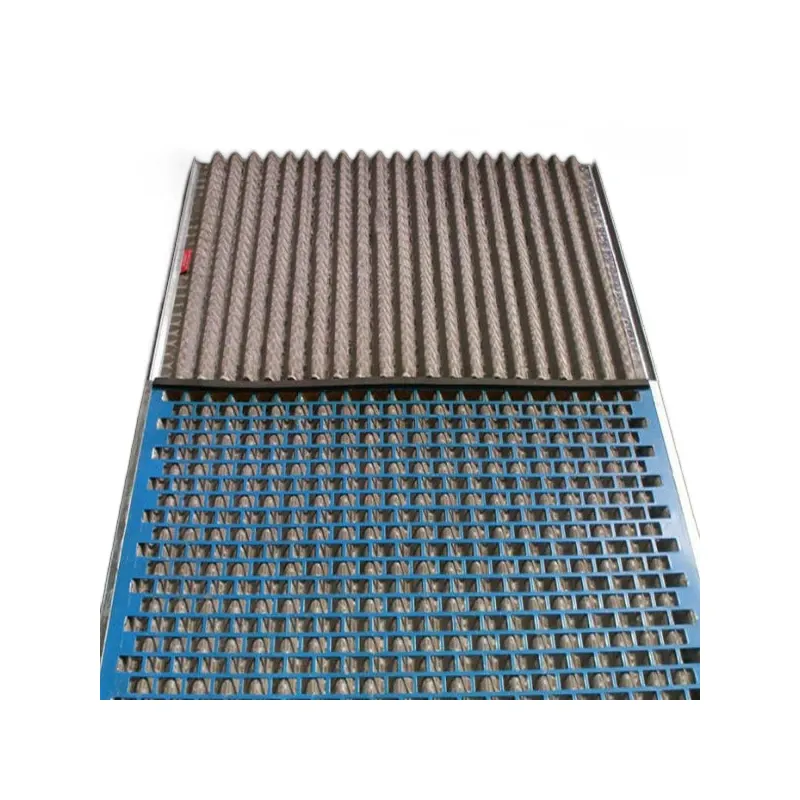

3D Shaker Screen: quick technicals

HF PetroMesh calls it a wave shale shaker screen—a multilayer SS304/316 cloth on steel or composite frames, formed with a 3D profile to open usable area and lift processing rates. It’s designed to be compatible with Derrick shakers (FLC 500/2000, Hyperpool) while clearly not an OEM part—important distinction.

| Parameter | Spec (≈, real-world may vary) |

|---|---|

| API Designation (RP 13C) | API 40–230 |

| D100 Cut Point | ≈ 38–410 μm (per API 13C tests) |

| Conductance | ≈ 0.7–2.3 kD/mm |

| Usable Area Gain vs Flat | ≈ 10–18% (mesh-dependent) |

| Frame | Composite or steel, epoxy bonded |

| Common Sizes | ≈ 1050×695 mm (FLC 500), 1200×635 mm (Hyperpool) |

| Fastening | Hookstrip / pin |

| Service Life | ≈ 300–800 hours (mud, G-force, and deck flatness dependent) |

How it’s made (process flow)

Materials: SS304/316L woven wire cloth; galvanized/SS support mesh; composite or steel frames. Methods: multi-layer lamination, corrugation forming, precision trimming, epoxy cure, and tension uniformity control. Testing: API RP 13C labeling (D100 and conductance), visual pore uniformity, adhesion shear, and frame flatness. Typical QC adds wet-sieve checks on finer API grades. Service life is validated on pilot shakers with weighted OBM/WBM; field correlation always trumps lab data, to be honest.

Where it’s used

Oil and gas shakers (Derrick FLC/Hyperpool), HDD river crossings, geothermal, and the odd mining cleanup circuit. The 3D form helps when you need finer cuts without drowning the decks. Many customers say the biggest surprise is steadier pool depth at comparable G-force—small thing, big impact.

Advantages vs flat screens

- Higher capacity at like-for-like API, thanks to the 3D profile similar to derrick pyramid screens.

- Better fines capture with API 100–170 without starving the pump.

- Composite frames resist warping; fewer mid-run leaks and hot spots.

Vendor snapshot (not all screens are equal)

| Vendor | Compliance | Lead Time | Price | Service Life | Notes |

|---|---|---|---|---|---|

| HF PetroMesh | API RP 13C labeled; ISO 9001 factory | ≈ 7–15 days | Mid | ≈ 400–800 hr | Custom mesh blends; repair plugs |

| Derrick OEM | API RP 13C | ≈ 3–7 days | High | ≈ 500–900 hr | Exact fit; premium composite |

| Generic Import | Mixed | ≈ 15–30 days | Low | ≈ 150–400 hr | Variable QC; watch tension |

Customization and real-world results

Options include SS304/316L cloth, anti-corrosion coatings for salt-laden air, hot-melt repair plugs, branded tags, and mesh stacks tuned for OBM vs WBM. One Middle East land rig swapped to 3D API 120/140: mud recovery improved ≈12% and screen changes dropped 25% over two wells—nothing flashy, just fewer stoppages. An HDD contractor on a 1.2 km river crossing reported saving ~18 drums of bentonite using API 100 3D panels versus flat API 100; pump draw stabilized, which was the real win.

Certs, standards, and a quick caveat

Factory quality systems run under ISO 9001:2015, while screen labeling follows API RP 13C for D100 and conductance. Materials conform to ASTM A240 for SS304/316. As always, derrick pyramid screens-style products from third parties are “compatible with,” not OEM. Ask for recent API 13C test sheets and a flatness check report; it seems basic, but it weeds out the pretenders.

References

- API RP 13C: Recommended Practice on Drilling Fluids Processing Measurement and Reporting.

- ASTM A240/A240M: Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip.

- ISO 9001:2015 Quality Management Systems — Requirements.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025