- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Why Derrick Pyramid Screens? More Capacity, Longer Life

derrick pyramid screens,derrick shaker screens,shale shaker screen,shale shaker screen china,shale shaker screen factory,shale shaker screen supplier is a key solution in the energy industry industry, specifically within Oil and gas exploration and production and Drilling solid control equipment and accessories. This article explores how Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- derrick pyramid screens,derrick shaker screens,shale shaker screen,shale shaker screen china,shale shaker screen factory,shale shaker screen supplier Overview

- Benefits & Use Cases of derrick pyramid screens,derrick shaker screens,shale shaker screen,shale shaker screen china,shale shaker screen factory,shale shaker screen supplier in Drilling solid control equipment and accessories

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in energy industry

- Conclusion on derrick pyramid screens,derrick shaker screens,shale shaker screen,shale shaker screen china,shale shaker screen factory,shale shaker screen supplier from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

derrick pyramid screens,derrick shaker screens,shale shaker screen,shale shaker screen china,shale shaker screen factory,shale shaker screen supplier Overview

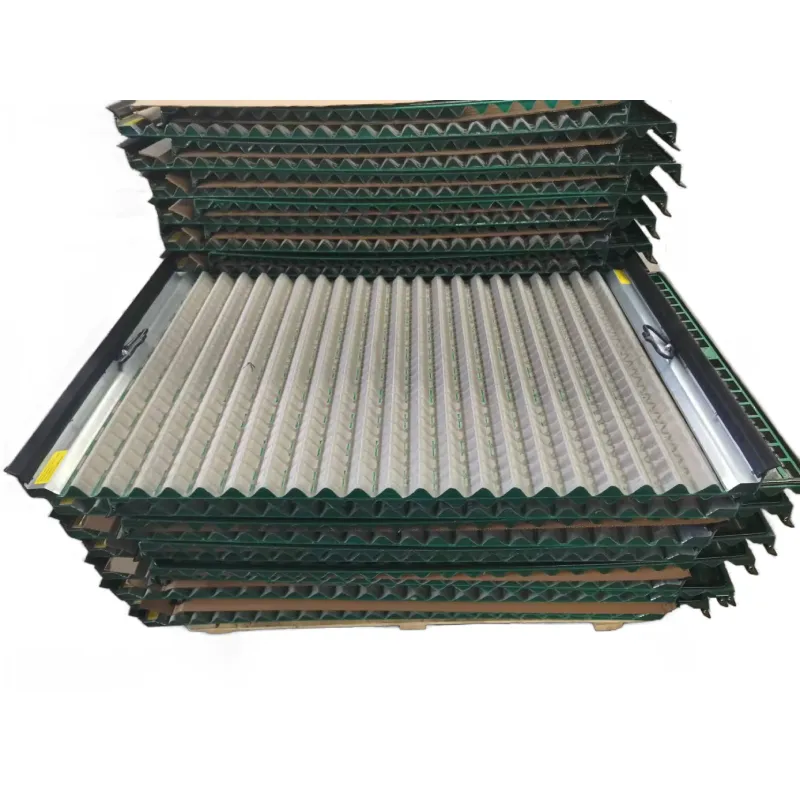

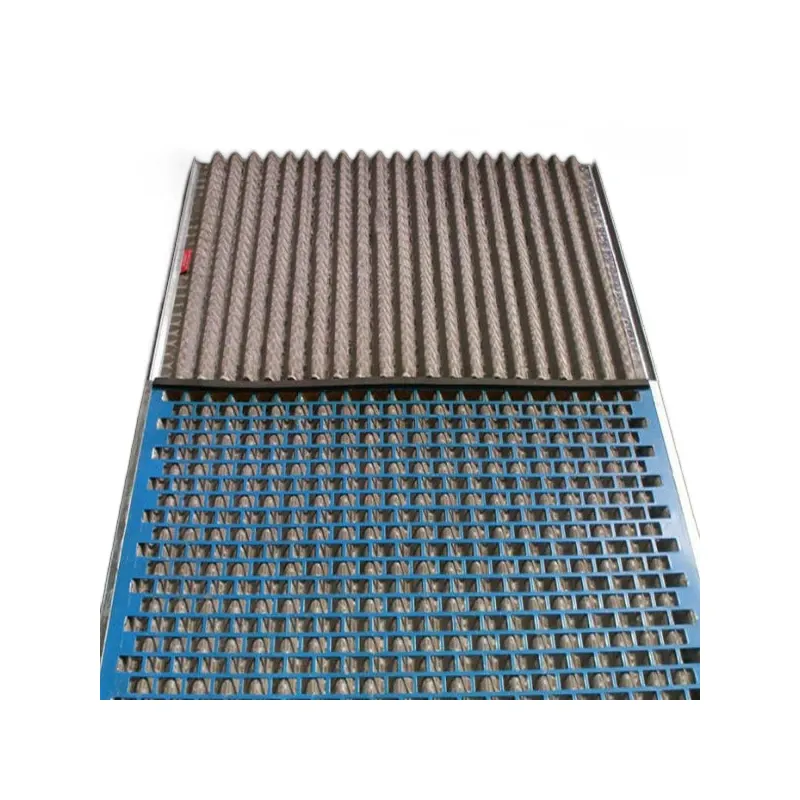

Shale shaker screens are the first—and most critical—line of defense in a drilling solids-control system. Among them, derrick pyramid screens (3D corrugated profiles) maximize non-blanked area and increase throughput compared with traditional flat panels. As replacement solutions compatible with leading shakers, derrick shaker screens convert vibration energy into efficient separation, maintaining fluid integrity and protecting downstream equipment.

At the core, a high-quality shale shaker screen uses multi-layer stainless steel mesh (commonly SS304/316L), bonded to composite or steel frames with precision apertures tested to API RP 13C (d100 and conductance). Typical API ranges span 20–325, covering coarse scalping to fine cut points. The 3D geometry of pyramid screens can boost flow capacity by 20–40% while preserving cut point, especially vital on high-G shakers and weighted mud systems.

Anping County Hangshun Wire Mesh Manufacture Co., Ltd is a proven shale shaker screen supplier and shale shaker screen factory in China, engineering consistent, high-strength bonding and tight API conformance for demanding rigs. From dimensions tailored to popular models to robust edging and gasket options, the company delivers dependable, field-ready screens that help operators manage solids loading, reduce mud losses, and stabilize drilling performance.

Benefits & Use Cases of derrick pyramid screens,derrick shaker screens,shale shaker screen,shale shaker screen china,shale shaker screen factory,shale shaker screen supplier in Drilling solid control equipment and accessories

On land and offshore rigs, derrick pyramid screens and other compatible derrick shaker screens are deployed on the primary shakers to remove drilled solids before they degrade into ultra-fines. Use cases span water-based, synthetic-based, and oil-based muds in vertical, deviated, and horizontal wells. The 3D corrugations increase turbulence across the mesh, reducing blinding and enhancing solids conveyance—an essential advantage during high ROP phases and while circulating LCM.

Key benefits include: higher processing rates at the same deck area, improved fluid recovery that reduces dilution cost, longer service life due to composite frames and advanced adhesives, and fast change-outs via precision hook-strip or pre-tensioned fit. As a specialized shale shaker screen supplier, Anping County Hangshun Wire Mesh Manufacture Co., Ltd optimizes mesh layering and wire diameters for balanced conductance and durability across API 60–200 ranges. Their engineering support helps operators select the right aperture and screen profile per well phase, formation abrasiveness, and shaker settings.

Whether you are standardizing on 3D shaker screens for multi-rig fleets or qualifying a shale shaker screen china manufacturing partner for contingency supply, Hangshun’s controlled QC process and stable lead times strengthen supply chain resilience while safeguarding mud quality at the rig site.

Cost, Maintenance & User Experience

Total cost of ownership for a shale shaker screen goes beyond purchase price. It includes service life, fluid recovery, change-out frequency, and impact on downstream equipment. By choosing high-conductance derrick pyramid screens, many operators report less dilution and lower mud losses, translating into measurable savings on base oil, chemicals, and waste handling. Composite frames typically deliver better fatigue resistance and corrosion immunity, helping extend screen life by double-digit percentages versus conventional steel frames in demanding environments.

Maintenance best practices—correct deck angle, proper tensioning, routine wash-downs, and timely replacement—further enhance ROI. Field feedback from E&P contractors indicates fewer unplanned screen swaps and steadier fluid properties when upgrading to Hangshun’s 3D shaker screens, particularly in long lateral sections with high solids loading. The company’s application engineers can recommend API grades per hole section to balance conductance and cut point, reducing the risk of prematurely plugging finer meshes.

Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports users with consistent quality batches, clear API labeling, and packaged spares for rapid rig-up. This lowers nonproductive time and stabilizes operating costs, giving B2B decision makers predictable performance and reliable inventory planning across multi-rig campaigns.

Sustainability & Market Trends in energy industry

Solids control directly influences an operator’s environmental footprint. Better separation at the shaker means less dilution, fewer consumables, and lower waste volumes. By maximizing fluid recovery, derrick shaker screens and advanced pyramid designs help reduce cuttings disposal and associated logistics. As ESG expectations grow and waste regulations tighten, optimizing primary separation is a practical lever for emissions and cost reduction.

Market trends point to higher G-force shakers, finer API grades, and a shift toward composite frames for strength-to-weight benefits and corrosion resistance. Partnering with a reputable shale shaker screen china manufacturer ensures capacity, agility, and cost efficiency without compromising quality. Anping County Hangshun Wire Mesh Manufacture Co., Ltd invests in precise mesh calibration, stable adhesives, and recyclable packaging to support responsible operations. Their continuous improvement mindset helps clients align with API RP 13C testing practices and internal HSE objectives while maintaining throughput on complex wells.

As drilling programs scale and encounter more abrasive intervals, B2B buyers prioritize proven screening performance, consistent QA documentation, and dependable lead times. Hangshun’s role as a specialized shale shaker screen factory and supplier positions them to meet these evolving requirements with technical depth and responsive service.

Conclusion on derrick pyramid screens,derrick shaker screens,shale shaker screen,shale shaker screen china,shale shaker screen factory,shale shaker screen supplier from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

Derrick pyramid screens and compatible derrick shaker screens are critical to efficient solids control, safeguarding mud properties and reducing operating costs. As a trusted shale shaker screen supplier and shale shaker screen factory in China, Anping County Hangshun Wire Mesh Manufacture Co., Ltd delivers 3D shaker screens engineered for throughput, durability, and API RP 13C performance consistency. For B2B decision makers seeking reliability and value, Hangshun provides technical guidance, stable quality, and on-time supply.

Contact us: email: sales@hfpetromesh.com

Visit our website: https://www.hfpetromesh.com

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025