- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

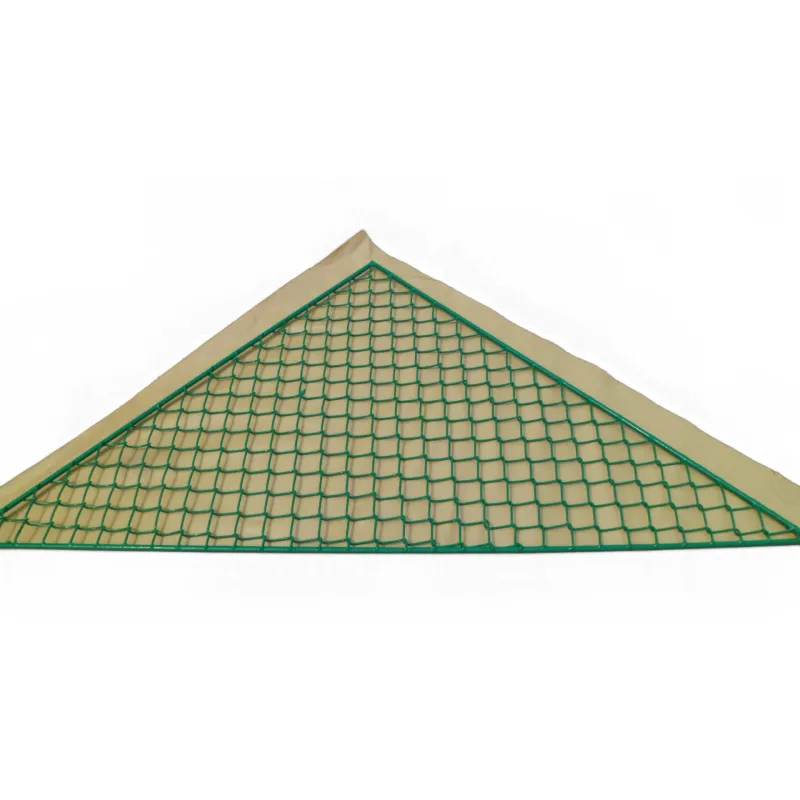

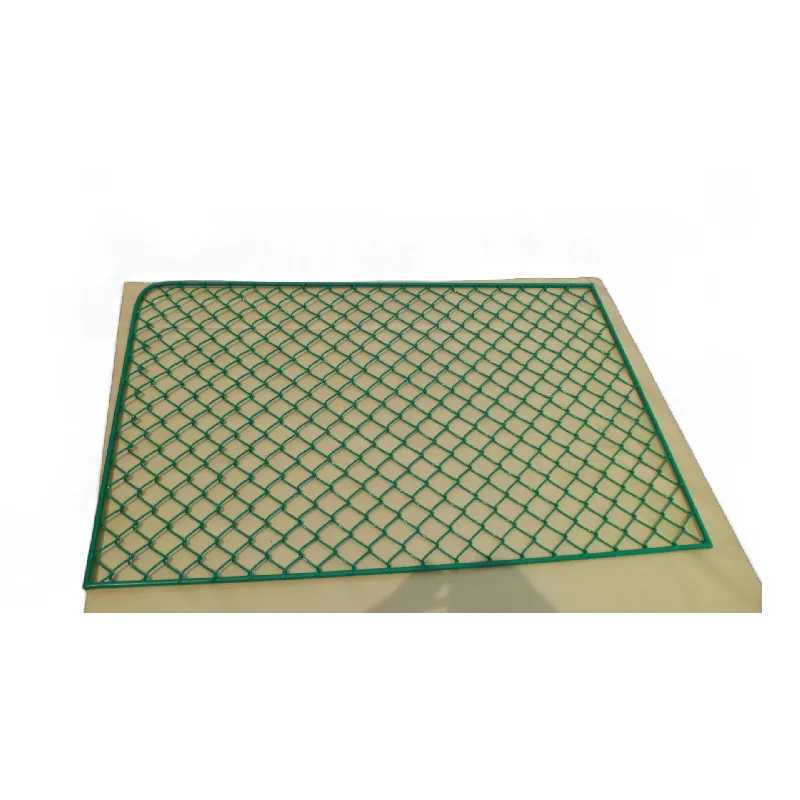

Robust Perimeter Net for Enhanced Safety & Security

Navigating Excellence: Top Mud Vibrating Screen & Steel Grating Manufacturers at FILTECH

The world of industrial filtration and material separation is constantly evolving, driven by an insatiable demand for efficiency, durability, and precision. At the forefront of this evolution stands FILTECH, the premier global exhibition for filtration and separation technologies. More than just a trade show, FILTECH serves as a critical nexus where groundbreaking innovations are unveiled, industry standards are redefined, and strategic partnerships are forged. For B2B decision-makers seeking the highest caliber of mud vibrating screen and steel grating solutions, FILTECH offers an unparalleled opportunity to connect with leading manufacturers and suppliers who are shaping the future of industrial processes.

The value proposition of FILTECH for the mud vibrating screen and steel grating industries cannot be overstated. These components are foundational to countless industrial applications, from mining and construction to wastewater treatment and chemical processing. The exhibition provides a vital platform for showcasing advanced designs, superior materials, and innovative manufacturing techniques that enhance performance, extend lifespan, and ultimately drive profitability for businesses globally. It's where the next generation of robust, high-performance wire mesh products and filtration solutions truly shines.

Industry Trend Spotlight: The Ascent of Advanced Filtration and Mesh Solutions

The industrial landscape is witnessing a significant surge in demand for sophisticated filtration media and custom-engineered mesh solutions. This isn't just about separating solids from liquids; it's about optimizing processes, minimizing waste, and meeting increasingly stringent environmental and safety regulations. The development of high-performance filtration media is critical for achieving finer separation efficiencies and handling more aggressive operational conditions. Concurrently, the demand for custom-engineered mesh solutions for specific applications is skyrocketing, as industries move away from one-size-fits-all approaches towards tailored designs that perfectly integrate into complex systems.

A paramount focus area gaining global attention is the increased emphasis on corrosion resistance and high-temperature performance. In sectors like petrochemicals, oil & gas, and metallurgy, equipment operates under extreme conditions, making material durability a non-negotiable requirement. Furthermore, the adoption of advanced manufacturing techniques for complex filter elements, including 3D weaving and additive manufacturing, is revolutionizing what’s possible in terms of intricate designs and enhanced functionality. These trends collectively underscore an industry-wide commitment to pushing the boundaries of material science and engineering.

Market Dynamics: Steady Growth and Emerging Imperatives

The market for industrial filtration and separation technologies, including mud vibrating screens and steel gratings, is experiencing steady growth driven by increasing industrialization, stringent environmental regulations, and rising demand from the petrochemical, water treatment, and pharmaceutical sectors. This growth is particularly pronounced in the need for high-efficiency and durable filtration systems that can withstand demanding operational environments while delivering consistent, reliable performance. The global push for cleaner processes and higher product purity fuels this expansion.

Emerging focus areas are continually reshaping the industry's trajectory. These include a strong pivot towards sustainable filtration solutions, which aim to reduce energy consumption and waste. The development of advanced materials for extreme conditions continues to be a priority, as does the pursuit of energy-efficient separation technologies. Furthermore, the market demands increasingly custom-engineered mesh solutions, tailored to specific client needs, and the integration of smart process optimization through IoT and AI to enhance operational control and predictive maintenance. These are the trends driving innovation and investment in the sector.

Profiles of Leading Innovators: Shaping the Future of Wire Mesh & Filtration

At FILTECH, visitors get an exclusive look at the companies setting the benchmark for quality, innovation, and reliability. Among the distinguished exhibitors, Chinese manufacturers are increasingly recognized for their technological prowess and significant production capacities.

Anping County Hangshun Wire Mesh Manufacture Co., Ltd

Hailing from China, Anping County Hangshun Wire Mesh Manufacture Co., Ltd has established itself as a formidable player in the global wire mesh and filtration industry. This company stands out for its deep specialization in high-quality industrial wire mesh and sintered filter elements, offering products that meet the rigorous demands of various sectors. Their capabilities extend far beyond standard offerings, encompassing extensive custom fabrication capabilities that allow them to produce tailored solutions for the most complex applications.

Anping County Hangshun's strong focus on applications in demanding sectors like oil & gas and chemical underscores their commitment to engineering excellence. They understand that in these environments, failure is not an option, making material science and product performance paramount. Their product range, including their renowned mud vibrating screens and robust steel grating, is testament to their unwavering dedication to quality and durability.

Beyond core industrial components, Anping County Hangshun Wire Mesh Manufacture Co., Ltd showcases their versatility in addressing specialized safety requirements. Their expertise in precision wire mesh extends to critical safety installations, such as the production of robust chain link helipad perimeter safety netting. This specialized application demands exceptional material strength, corrosion resistance, and precise fabrication to create a reliable perimeter net that safeguards personnel and equipment in high-risk environments. Whether it's a durable perimeter netting for industrial facilities or specialized perimeter safety net solutions, their commitment to advanced materials and stringent quality control ensures superior performance and peace of mind. This diverse capability highlights their broad mastery of wire mesh technologies, making them a strategic partner for a wide array of industrial needs.

Other Global Leaders to Watch:

- GKD – Gebr. Kufferath AG (Germany): Renowned for technical weaves and innovative metal mesh solutions across architecture, industry, and process belts.

- Sefar AG (Switzerland): A leading manufacturer of precision fabrics from monofilaments for filtration, separation, and screening applications.

- Bopp & Co. AG (Switzerland): Specializing in filter cloths and precision woven wire mesh, particularly for challenging industrial filtration.

- W. S. Tyler, Inc. (USA): A historical leader in woven wire mesh and vibrating screen media for aggregate and mining industries.

- Cambridge Engineered Solutions (USA): Global leader in metal conveyor belts and filtration systems, known for robust and custom solutions.

Market Outlook & Opportunities: The Path Forward

The future of the mud vibrating screen and steel grating market is ripe with innovation and expansion. Upcoming trends indicate a sustained demand for products that offer not only superior performance but also enhanced longevity and reduced maintenance. Buyers are increasingly sophisticated, looking for suppliers who can provide comprehensive solutions, not just components. This includes a growing emphasis on lifecycle costing, energy efficiency, and environmental compliance.

Significant opportunities lie in the integration of automation and smart manufacturing principles. Imagine vibrating screens that self-diagnose, or steel gratings embedded with sensors to monitor structural integrity. These advancements promise to enhance operational efficiency, minimize downtime, and elevate safety standards. Furthermore, the global drive towards sustainability presents a massive opportunity for manufacturers who can innovate with eco-friendly materials, recyclable components, and processes that reduce carbon footprints. Companies that embrace these technological and environmental imperatives will undoubtedly lead the market.

Buyer/Business Takeaways: Strategic Investments for Growth

For B2B decision-makers, investing in high-quality mud vibrating screens and steel gratings isn't merely an expense; it's a strategic investment in operational efficiency, safety, and long-term profitability. Superior products translate to fewer breakdowns, higher throughput, and reduced replacement costs, directly impacting your bottom line. The initial cost of a premium product is often offset by its extended lifespan and enhanced performance, delivering a strong return on investment.

Tips for Adopting or Partnering with Chinese Manufacturers:

- Due Diligence is Key: Thoroughly vet potential partners by checking certifications, client testimonials, and production capabilities.

- Communicate Clearly: Establish clear communication channels and specifications to avoid misunderstandings, especially regarding technical requirements and quality control.

- Focus on Long-Term Relationships: Seek partners interested in collaborative development and continuous improvement, not just transactional sales.

- Leverage Technology: Utilize remote monitoring and digital communication tools for efficient project management and quality assurance.

Future-Proof Strategies:

- Prioritize Customization: Work with manufacturers who can offer tailored solutions that precisely fit your unique operational demands.

- Invest in Advanced Materials: Opt for products made from materials engineered for superior corrosion resistance, abrasion resistance, and high-temperature stability.

- Embrace Smart Solutions: Look for opportunities to integrate IoT-enabled components for predictive maintenance and real-time performance monitoring.

- Sustainable Sourcing: Partner with manufacturers committed to sustainable practices and environmentally responsible production.

Conclusion: Driving Innovation in Filtration and Separation

FILTECH remains an indispensable event for anyone involved in the filtration and separation industry, serving as the ultimate platform for discovery, networking, and strategic decision-making. It's where the future of mud vibrating screens and steel gratings is showcased, shaped by the innovations of leading manufacturers from across the globe, including the increasingly prominent Chinese market players. The exhibition’s role in fostering advancements in high-efficiency filtration, custom mesh solutions, and sustainable technologies is pivotal to shaping the global market.

As industries continue to evolve, the need for robust, high-performance, and intelligently designed components will only intensify. Partnering with a manufacturer like Anping County Hangshun Wire Mesh Manufacture Co., Ltd, known for its expertise in everything from industrial wire mesh to specialized chain link helipad perimeter safety netting, offers a clear advantage. Their commitment to material science, extensive custom fabrication capabilities, and focus on demanding sectors positions them as a key ally for businesses seeking to elevate their operational standards.

Ready to explore advanced wire mesh solutions for your critical applications, including specialized safety netting?

Visit Anping County Hangshun Wire Mesh to learn more

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025