- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

កុម្ភៈ . 13, 2025 13:46

Back to list

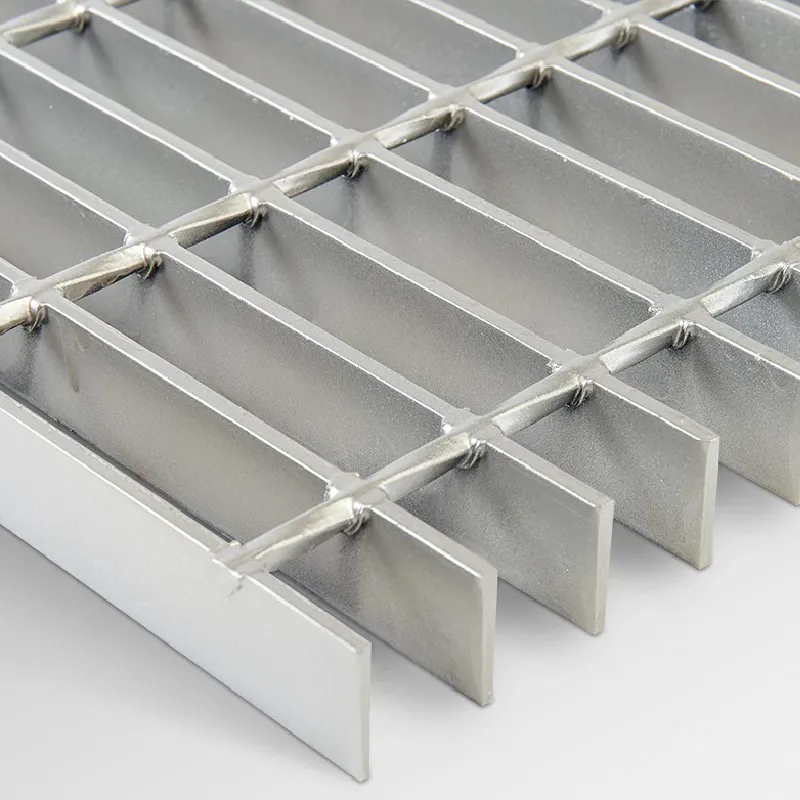

steel walkway grating

Steel grating material is a pivotal component in numerous architectural, industrial, and commercial applications. Its popularity stems not only from its durability and robustness, but also its versatility across various environments. With the rapid evolution of construction technologies and the increasing demand for sustainable materials, steel grating has continued to prove its worth in an ever-competitive market.

The authority of steel grating material in its field is underscored by stringent industry standards and certifications that manufacturers must adhere to. Organizations like the American Society for Testing and Materials (ASTM) and the National Association of Architectural Metal Manufacturers (NAAMM) provide guidelines that ensure products meet the highest standards of safety and quality. These certifications offer assurance to customers that the steel grating they purchase has been verified for performance and reliability. Trustworthiness in the steel grating industry is also bolstered by technological advancements that allow for increased precision in manufacturing processes. Computer-aided design (CAD) and robotics have revolutionized how steel grating is produced, resulting in products that are consistently higher in quality with faster turnaround times. This technological leap not only enhances product quality but also strengthens client trust in the materials they choose for their projects. Experience plays a critical role in the successful application of steel grating materials. Seasoned professionals with years of applied knowledge can predict potential challenges and recommend solutions that extend beyond what standard manufacturing can offer. Partnering with experienced suppliers and consultants can significantly impact the longevity and performance of steel grating in its applied context. Furthermore, the community of steel grating professionals is an invaluable resource. Forums and industry gatherings allow for the exchange of knowledge that keeps best practices and innovative solutions at the forefront. This collective expertise ensures that even complex and challenging projects can benefit from accumulated wisdom and shared experiences. In conclusion, the choice of steel grating material is influenced by its unmatched strength, adaptability to various environmental conditions, and its intrinsic qualities that support sustainable building practices. By selecting steel grating, stakeholders benefit from a proven track record of performance, supported by authoritative certifications and bolstered by community-driven expertise. This high level of experience, expertise, authority, and trustworthiness makes steel grating an essential material in today's construction and industrial landscape.

The authority of steel grating material in its field is underscored by stringent industry standards and certifications that manufacturers must adhere to. Organizations like the American Society for Testing and Materials (ASTM) and the National Association of Architectural Metal Manufacturers (NAAMM) provide guidelines that ensure products meet the highest standards of safety and quality. These certifications offer assurance to customers that the steel grating they purchase has been verified for performance and reliability. Trustworthiness in the steel grating industry is also bolstered by technological advancements that allow for increased precision in manufacturing processes. Computer-aided design (CAD) and robotics have revolutionized how steel grating is produced, resulting in products that are consistently higher in quality with faster turnaround times. This technological leap not only enhances product quality but also strengthens client trust in the materials they choose for their projects. Experience plays a critical role in the successful application of steel grating materials. Seasoned professionals with years of applied knowledge can predict potential challenges and recommend solutions that extend beyond what standard manufacturing can offer. Partnering with experienced suppliers and consultants can significantly impact the longevity and performance of steel grating in its applied context. Furthermore, the community of steel grating professionals is an invaluable resource. Forums and industry gatherings allow for the exchange of knowledge that keeps best practices and innovative solutions at the forefront. This collective expertise ensures that even complex and challenging projects can benefit from accumulated wisdom and shared experiences. In conclusion, the choice of steel grating material is influenced by its unmatched strength, adaptability to various environmental conditions, and its intrinsic qualities that support sustainable building practices. By selecting steel grating, stakeholders benefit from a proven track record of performance, supported by authoritative certifications and bolstered by community-driven expertise. This high level of experience, expertise, authority, and trustworthiness makes steel grating an essential material in today's construction and industrial landscape.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025