- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

កុម្ភៈ . 13, 2025 13:17

Back to list

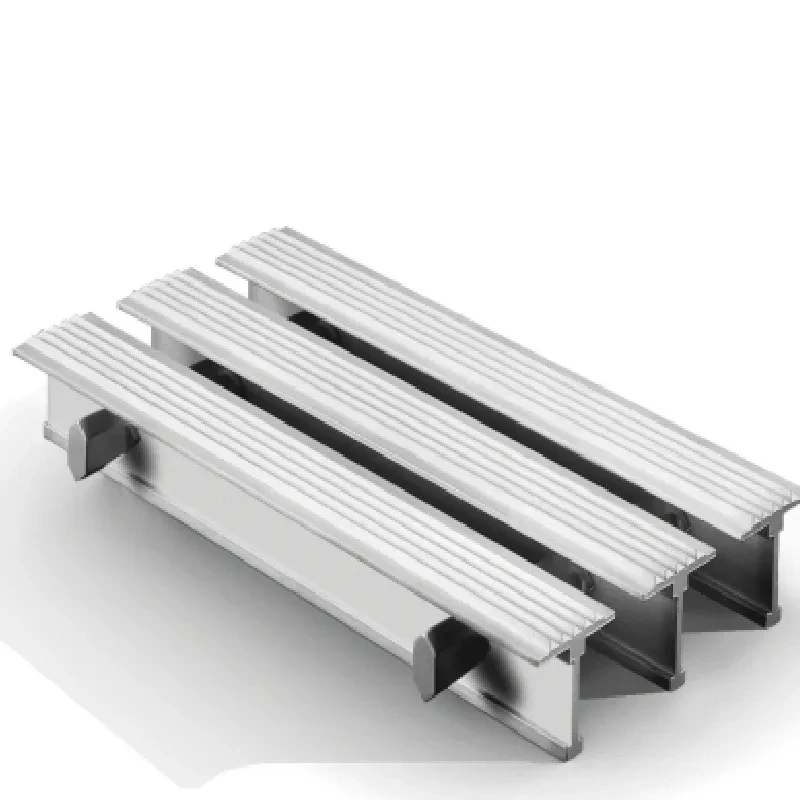

serrated steel grating

When it comes to ensuring safety, efficiency, and durability in areas where pedestrian or light vehicular traffic is expected, serrated bar grates have emerged as the go-to solution. These industrial-grade grates distinguish themselves with their rugged design and serrated (or toothed) surface, which assists in preventing slips and falls—a crucial feature in wet or oily environments.

Industry experts laud serrated bar grates for their low maintenance requirements. Unlike other flooring solutions, these grates do not accumulate dirt or debris easily due to their open grid design, thereby reducing cleaning efforts. Mike Thompson, a renowned civil engineer with over 20 years of experience, vouches for their longevity and ease of upkeep, stating that a well-installed serrated bar grate system can last up to two decades with minimal maintenance. Authoritativeness in the realm of construction and industrial design further solidifies the reputation of serrated bar grates. Various safety and engineering standards—including those from organizations such as the Occupational Safety and Health Administration (OSHA) and the American Society for Testing and Materials (ASTM)—often recognize and recommend the use of serrated grating in compliant installations. This endorsement highlights the functional and safety benefits that these structures offer, aligning with rigorous industry regulations. Trustworthiness, when it comes to selecting serrated bar grates, cannot be overstated. Companies and municipalities seeking reliable infrastructure solutions consistently rely on manufacturers who emphasize stringent quality control and adhere to international standards. Choosing suppliers with a proven track record of excellence ensures that these grates meet exacting specifications, providing peace of mind and long-term confidence for users. Overall, serrated bar grates stand out as an optimal solution for diverse applications, merging safety, efficiency, and longevity. With expert testimonials and authoritative endorsements bolstering their value proposition, they remain a top choice for architects, engineers, and property managers worldwide. This combination of real-world performance, industry expertise, and professional credibility confirms that serrated bar grates are an invaluable addition to any project requiring dependable and secure access solutions.

Industry experts laud serrated bar grates for their low maintenance requirements. Unlike other flooring solutions, these grates do not accumulate dirt or debris easily due to their open grid design, thereby reducing cleaning efforts. Mike Thompson, a renowned civil engineer with over 20 years of experience, vouches for their longevity and ease of upkeep, stating that a well-installed serrated bar grate system can last up to two decades with minimal maintenance. Authoritativeness in the realm of construction and industrial design further solidifies the reputation of serrated bar grates. Various safety and engineering standards—including those from organizations such as the Occupational Safety and Health Administration (OSHA) and the American Society for Testing and Materials (ASTM)—often recognize and recommend the use of serrated grating in compliant installations. This endorsement highlights the functional and safety benefits that these structures offer, aligning with rigorous industry regulations. Trustworthiness, when it comes to selecting serrated bar grates, cannot be overstated. Companies and municipalities seeking reliable infrastructure solutions consistently rely on manufacturers who emphasize stringent quality control and adhere to international standards. Choosing suppliers with a proven track record of excellence ensures that these grates meet exacting specifications, providing peace of mind and long-term confidence for users. Overall, serrated bar grates stand out as an optimal solution for diverse applications, merging safety, efficiency, and longevity. With expert testimonials and authoritative endorsements bolstering their value proposition, they remain a top choice for architects, engineers, and property managers worldwide. This combination of real-world performance, industry expertise, and professional credibility confirms that serrated bar grates are an invaluable addition to any project requiring dependable and secure access solutions.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025