- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

កុម្ភៈ . 13, 2025 14:16

Back to list

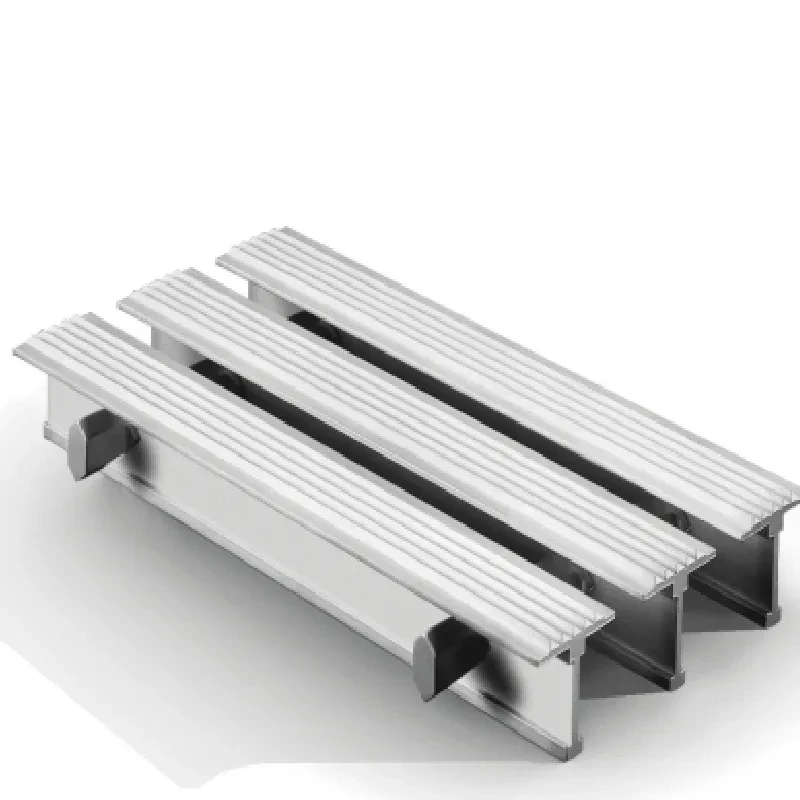

serrated steel grating

Serrated steel flat bars are increasingly gaining traction in various industrial applications due to their excellent grip, durability, and versatility. These flat bars, characterized by their serrated edges, are engineered to provide enhanced traction and increased surface area, making them ideal for environments where safety and durability are paramount.

Installation of serrated steel flat bars is straightforward, yet it should be executed by professionals to guarantee safety and structural integrity. The precision of the serrated edges requires alignment and fixation to be meticulously observed, ensuring the bars function as intended. The expertise of installation teams contributes to the overall trustworthiness of the structure, assuring users of its safety and durability. The credibility of serrated steel flat bars as a dependable material stems from both industry research and field testing. Extensive testing under various conditions—ranging from temperature extremes to load capacities—proves their resilience and versatility. Industry certifications and compliance with global safety standards further reinforce their authoritative standing in the market. Building trust with clients and end-users is crucial. Providing comprehensive technical documentation that outlines material properties, installation procedures, and maintenance tips ensures transparency and facilitates informed decision-making. This strengthens buyer confidence, highlighting the manufacturer's commitment to quality and safety. In conclusion, serrated steel flat bars exemplify a blend of innovative engineering, reliable performance, and adaptability to challenging environments. Their distinct features meet critical safety standards while offering exceptional durability and customization options. As industries continue to demand solutions that integrate reliability with practicality, serrated steel flat bars will indisputably remain a top-tier choice for applications necessitating rugged, durable, and safe materials.

Installation of serrated steel flat bars is straightforward, yet it should be executed by professionals to guarantee safety and structural integrity. The precision of the serrated edges requires alignment and fixation to be meticulously observed, ensuring the bars function as intended. The expertise of installation teams contributes to the overall trustworthiness of the structure, assuring users of its safety and durability. The credibility of serrated steel flat bars as a dependable material stems from both industry research and field testing. Extensive testing under various conditions—ranging from temperature extremes to load capacities—proves their resilience and versatility. Industry certifications and compliance with global safety standards further reinforce their authoritative standing in the market. Building trust with clients and end-users is crucial. Providing comprehensive technical documentation that outlines material properties, installation procedures, and maintenance tips ensures transparency and facilitates informed decision-making. This strengthens buyer confidence, highlighting the manufacturer's commitment to quality and safety. In conclusion, serrated steel flat bars exemplify a blend of innovative engineering, reliable performance, and adaptability to challenging environments. Their distinct features meet critical safety standards while offering exceptional durability and customization options. As industries continue to demand solutions that integrate reliability with practicality, serrated steel flat bars will indisputably remain a top-tier choice for applications necessitating rugged, durable, and safe materials.

Share

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025