- Iðnaðarsvæði, suður af Anping Town, Hengshui, Hebei, Kína.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Enska

Enska  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Enska

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Unlocking Efficiency In Solids Control: The World Of Shale Shaker Solutions

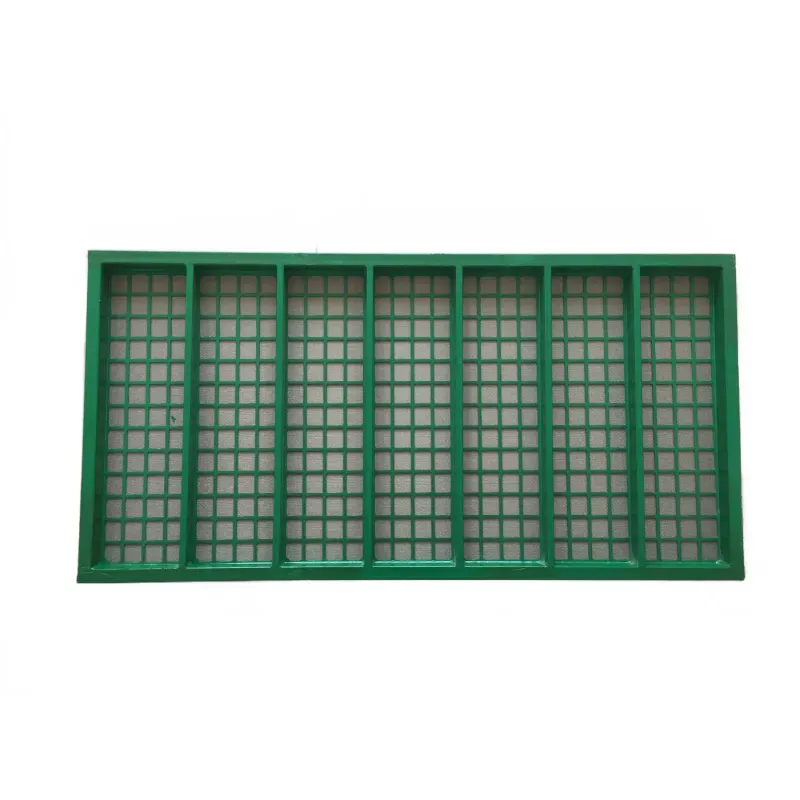

In the demanding landscape of oil and gas drilling, effective solids control is critical for operational success and environmental safety. At the heart of this process lie advanced components like shale screen, swaco shaker screens, shale shaker screen mesh, shale shaker screen material, and considerations around shale shaker screen price. These elements work in tandem to separate cuttings from drilling fluids, optimize fluid recycling, and enhance overall rig efficiency.

The Core Role of Shale Screen in Drilling Operations

A shale screen serves as the first line of defense in solids - control systems, tasked with separating drilled cuttings from drilling mud. These screens are designed to withstand high - impact environments, where constant exposure to abrasive materials is inevitable. For example, in horizontal drilling projects, shale screens with precise mesh sizes are used to capture fine cuttings, ensuring that only clean mud is recirculated. The design of these screens often incorporates tensioned frames and reinforced edges to prevent premature wear, even under heavy loads.

Innovations in Swaco Shaker Screens

Swaco shaker screens represent a benchmark in high - performance solids control. Engineered for compatibility with Swaco shale shakers, these screens feature advanced designs that balance durability and separation efficiency. For instance, some models use a combination of stainless - steel wire and composite materials to create a robust yet flexible mesh. This allows the screen to handle high - volume flow rates while maintaining strict separation standards. The modular design of swaco shaker screens also simplifies installation and replacement, reducing downtime during screen changes.

The Impact of Shale Shaker Screen Mesh

The shale shaker screen mesh is a critical factor in determining separation accuracy. Mesh sizes range from coarse (e.g., 20 mesh) for removing large cuttings to ultra - fine (e.g., 300 mesh) for capturing minute particles. In deep - sea drilling, where drilling fluids are expensive and environmental regulations are strict, fine mesh screens are essential for recovering valuable mud components. Additionally, the weave pattern of the mesh—such as plain weave or twill weave—affects its open area and durability. A higher open area allows for greater fluid throughput, while a tighter weave enhances solids retention.

Exploring Shale Shaker Screen Materials

The choice of shale shaker screen material directly influences performance and longevity. Stainless steel is a common choice due to its corrosion resistance and strength, making it suitable for harsh drilling environments with high salinity or acidic fluids. Composite materials, such as polyurethane - coated screens, offer superior abrasion resistance and flexibility, reducing the risk of mesh deformation under stress. Some advanced screens integrate hybrid materials, combining the rigidity of metal frames with the durability of composite meshes. This hybrid approach maximizes both screening efficiency and service life.

Factors Influencing Shale Shaker Screen Price

The shale shaker screen price is shaped by multiple variables, including material, design complexity, and screen size. Stainless - steel screens with fine meshes typically command higher prices due to their precision manufacturing and corrosion resistance. Composite screens, while often more expensive upfront, may offer long - term cost savings due to their extended lifespan and reduced maintenance needs. Custom - designed screens for specialized rigs or unique drilling conditions also tend to be pricier. Bulk purchasing and long - term supplier partnerships can help mitigate costs for operators.

FAQ: Key Insights for Shale Shaker Screen Users

How often should shale shaker screens be replaced?

Replacement frequency depends on factors like drilling intensity, cuttings abrasiveness, and screen quality. In general, screens may need replacement every 50 to 200 hours of operation. Signs of wear include visible tears in the mesh, reduced separation efficiency (e.g., mud carrying excessive solids), or uneven wear patterns. Regular inspections during rig downtime can help identify when screens near the end of their service life.

Can screen mesh size affect drilling fluid recovery?

Yes, mesh size directly impacts fluid recovery and solids removal. A coarser mesh allows more fluid to pass through quickly but may leave larger cuttings in the mud, while a finer mesh captures more solids but can restrict fluid flow. Operators must balance these factors based on their specific drilling goals, such as maximizing mud recovery in costly offshore operations or prioritizing solids removal in shallow, debris - rich formations.

What maintenance practices extend screen lifespan?

To prolong screen life, ensure proper tensioning during installation—loose screens can vibrate excessively and wear prematurely. Regularly clean screens to remove stuck cuttings, using low - pressure water or non - abrasive tools to avoid damaging the mesh. Avoid overloading screens with excessive mud flow, as this can cause mechanical stress and reduce separation efficiency.

Are composite screen materials suitable for all drilling environments?

Composite materials like polyurethane are highly versatile but may have limitations in extreme conditions. They excel in moderate - to - high - abrasion environments and are ideal for water - based muds. However, in high - temperature applications or with oil - based muds, stainless - steel screens may be more appropriate due to their thermal stability. Always consult manufacturer guidelines for material compatibility.

How can operators optimize costs when purchasing shale shaker screens?

To optimize costs, conduct a total cost of ownership (TCO) analysis that considers both upfront price and longevity. Cheaper screens may require more frequent replacements, increasing overall expenses. Partner with suppliers who offer testing services to identify the best screen type for specific drilling conditions. Additionally, explore remanufacturing options for worn screens, which can provide cost - effective alternatives to buying new.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingFréttirNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedFréttirNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedFréttirNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMFréttirNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipFréttirNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipFréttirNov.10,2025