- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Steel walkway grating: anti-slip, durable—why choose ours?

steel walkway grating, metal walkways gratings, steel walkway mesh, walkway grates are key solutions in the manufacturing industry, specifically within Fabricated metal products and the Manufacturing of structural metal products. This article explores how Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports professionals with durable, high-performance products, and explains why these products are an ideal choice for businesses in these sectors.

Table of Contents

- steel walkway grating, metal walkways gratings, steel walkway mesh, walkway grates Overview

- Benefits & Use Cases of steel walkway grating, metal walkways gratings, steel walkway mesh, walkway grates in Manufacturing of structural metal products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on steel walkway grating, metal walkways gratings, steel walkway mesh, walkway grates from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

steel walkway grating, metal walkways gratings, steel walkway mesh, walkway grates Overview

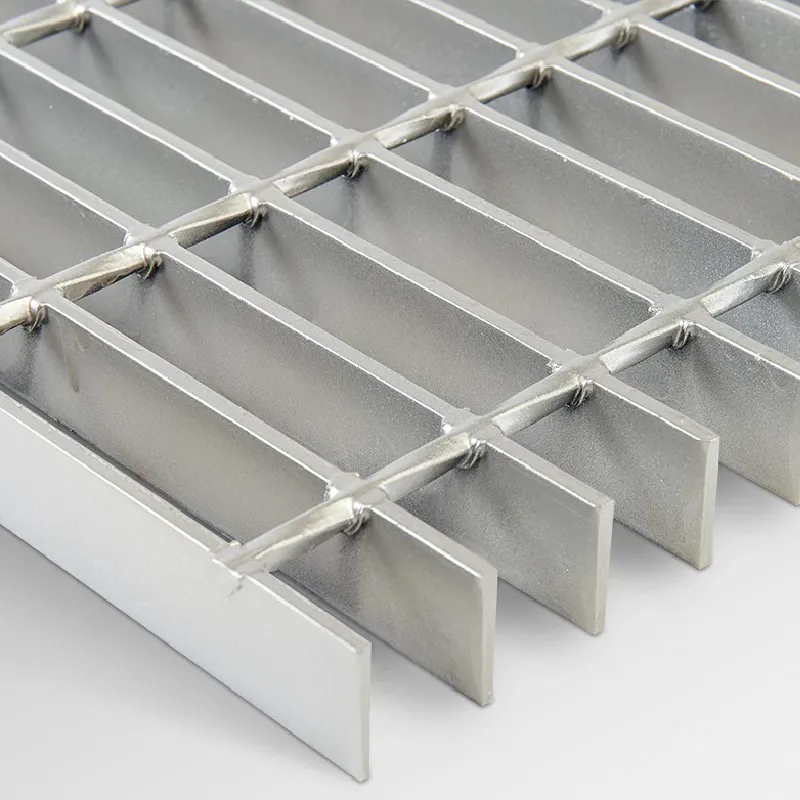

Steel walkway grating—also called metal walkways gratings, steel walkway mesh, or walkway grates—is a load-bearing, open-grid flooring manufactured from carbon steel or stainless steel and assembled by welding or press-locking. In the Manufacturing of structural metal products, these systems create safe, slip-resistant walkways, platforms, catwalks, and mezzanines that combine high load capacity with efficient drainage, airflow, and debris shedding. Typical specifications include bearing bar depth 25–65 mm, thickness 3–6 mm, and common pitches such as 30/100 or 34/100, with plain or serrated surfaces. Finishes include mill black, primer-painted, and hot-dip galvanized to extend service life in corrosive environments.

Anping County Hangshun Wire Mesh Manufacture Co., Ltd engineers and produces welded bar grating and press-locked grating with tight tolerances, consistent flatness, and quality-controlled galvanizing. Custom panel sizes, cutouts for penetrations, kick plates, toe boards, checker plates, and clip fasteners are available to streamline installation on site. In recent projects for fabrication yards and process plants, Hangshun’s hot-dip galvanized serrated steel walkway grating improved slip resistance and reduced maintenance interventions by providing robust, easy-to-clean walk surfaces integrated with handrail and stair systems.

Benefits & Use Cases of steel walkway grating, metal walkways gratings, steel walkway mesh, walkway grates in Manufacturing of structural metal products

Across structural metal manufacturing, steel walkway mesh is specified for factory platforms, conveyor walkways, pipe racks, mezzanines, rooftop service areas, trench covers, and bridge maintenance paths. Compared with solid plate, walkway grates offer a superior strength-to-weight ratio, excellent drainage, and natural ventilation—key advantages in welding bays, paint lines, and process areas. Serrated bearing bars deliver reliable traction under wet or oily conditions, while open areas simplify housekeeping and inspection routines.

From a competitive standpoint, Anping County Hangshun Wire Mesh Manufacture Co., Ltd designs metal walkways gratings that balance load capacity with installation efficiency. Benefits include standardized panel modules, banded edges for rigidity, matching stair treads, and quick-fit clips that avoid hot works during retrofit. Materials range from Q235/Q345 carbon steel to stainless steel 304/316, with hot-dip galvanizing for long-term corrosion protection. Hangshun’s engineering support—covering span/load selection, detailing, and edge treatment—helps fabricators and EPCs meet safety codes and project schedules while minimizing field rework.

Cost, Maintenance & User Experience

Total cost of ownership for steel walkway grating is attractive due to long service life, low maintenance, and rapid installation. Hot-dip galvanized grating commonly delivers many years of protection in industrial atmospheres, reducing repainting cycles and shutdowns. The open-grid design cuts cleaning time because dust and liquids pass through, and serrated profiles maintain slip resistance without coatings. Standardized panels, edge banding, and universal clips accelerate installation, lowering labor costs and crane time compared with heavier plate floors.

Customers in the Fabricated metal products sector value the ROI achieved by lighter support steel, simplified retrofits around equipment, and fewer site adjustments. Feedback frequently highlights consistent galvanizing quality, accurate panel squareness, and reliable delivery deadlines—key factors that keep projects on track. Routine care includes periodic visual inspections, removal of debris, and touch-up of any localized damage from impacts. With proper selection of material and finish for the environment, users report stable performance and minimal lifecycle expense.

Sustainability & Market Trends in manufacturing

Steel walkway grating aligns with sustainability priorities in manufacturing. Steel is highly recyclable, and the longevity provided by hot-dip galvanizing reduces material turnover and waste. The open-grid structure supports natural drainage and airflow, which can lower washdown water needs and help maintain cleaner, drier work areas. Market trends favor modular, prefabricated components, stronger slip resistance, and designs that integrate seamlessly with BIM-driven detailing and offsite fabrication—areas where precision-made walkway grates deliver clear value.

Anping County Hangshun Wire Mesh Manufacture Co., Ltd approaches these trends with a focus on durability, efficient material usage, and packaging that protects products while minimizing waste. The company’s ability to supply tailor-made steel walkway mesh and walkway grates—matched to environmental exposure and load criteria—helps clients meet evolving safety expectations and sustainability goals. With continuous process improvement and quality assurance at the core, Hangshun supports greener, safer, and more productive facilities worldwide.

Conclusion on steel walkway grating, metal walkways gratings, steel walkway mesh, walkway grates from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

For fabricators, EPCs, and plant owners, steel walkway grating provides dependable strength, traction, and drainage with a low total cost of ownership. As a specialized manufacturer, Anping County Hangshun Wire Mesh Manufacture Co., Ltd delivers engineered metal walkways gratings and steel walkway mesh that fit demanding industrial environments and tight schedules. Discuss your specifications with our team and streamline your next platform or catwalk project.

Contact us: email: sales@hfpetromesh.com

Visit our website: https://www.hfpetromesh.com

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025