- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Shale Shaker Screen with API Quality at Factory Price?

[shale shaker screen,shale shaker screen mesh,shale shaker screen suppliers,shale shaker screen material,shale shaker screen for sale,shale shaker screen supplier,shale shaker screen factory,shale shaker screen china,shale shaker screen price,shale shakerscreen manufacturers,shale shaker screens for sale] is a key solution in the Oil and gas industry industry, specifically within Oil and gas equipment and services and Drilling solid control equipment and accessories. This article explores how Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- [shale shaker screen,shale shaker screen mesh,shale shaker screen suppliers,shale shaker screen material,shale shaker screen for sale,shale shaker screen supplier,shale shaker screen factory,shale shaker screen china,shale shaker screen price,shale shakerscreen manufacturers,shale shaker screens for sale] Overview

- Benefits & Use Cases of [shale shaker screen,shale shaker screen mesh,shale shaker screen suppliers,shale shaker screen material,shale shaker screen for sale,shale shaker screen supplier,shale shaker screen factory,shale shaker screen china,shale shaker screen price,shale shakerscreen manufacturers,shale shaker screens for sale] in Drilling solid control equipment and accessories

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Oil and gas industry

- Conclusion on [shale shaker screen,shale shaker screen mesh,shale shaker screen suppliers,shale shaker screen material,shale shaker screen for sale,shale shaker screen supplier,shale shaker screen factory,shale shaker screen china,shale shaker screen price,shale shakerscreen manufacturers,shale shaker screens for sale] from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

[shale shaker screen,shale shaker screen mesh,shale shaker screen suppliers,shale shaker screen material,shale shaker screen for sale,shale shaker screen supplier,shale shaker screen factory,shale shaker screen china,shale shaker screen price,shale shakerscreen manufacturers,shale shaker screens for sale] Overview

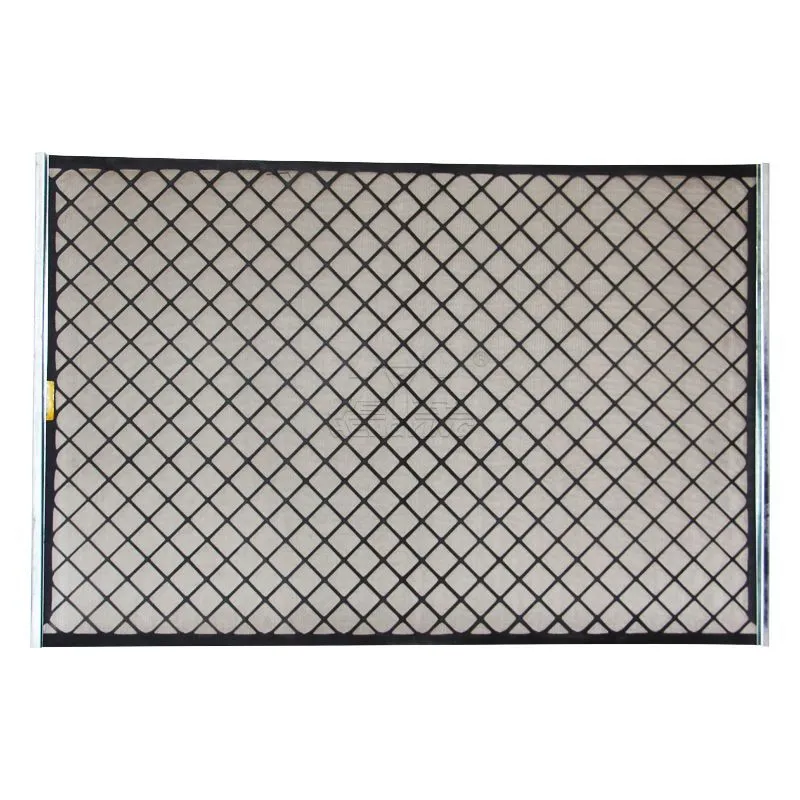

In modern solids control systems, the shale shaker screen is the first—and most critical—barrier for removing cuttings and preserving drilling fluid properties. A hook strip soft screen, such as those offered by Anping County Hangshun Wire Mesh Manufacture Co., Ltd, combines multiple layers of stainless steel wire cloth (commonly SS304, SS316, or SS316L) bonded to a support mesh and finished with hooked edges for secure tensioning. Typical shale shaker screen mesh selections range from API 20 to API 325+, enabling tailored cut points across top-hole, intermediate, and production intervals. The right shale shaker screen material and layering strategy (2–4 layers) deliver high conductance, fine separation, and extended life, while anti-blinding patterns help maintain flow in sticky formations. As an experienced shale shaker screen supplier and shale shaker screen factory in China, Hangshun builds screens compatible with major shaker models and manufactures to stringent quality standards. Whether you’re evaluating a shale shaker screen for sale for a new rig or optimizing your inventory across a fleet, precise mesh calibration, consistent bonding, and robust hooks are the difference between steady mud properties and costly dilution.

Benefits & Use Cases of [shale shaker screen,shale shaker screen mesh,shale shaker screen suppliers,shale shaker screen material,shale shaker screen for sale,shale shaker screen supplier,shale shaker screen factory,shale shaker screen china,shale shaker screen price,shale shakerscreen manufacturers,shale shaker screens for sale] in Drilling solid control equipment and accessories

Across onshore and offshore rigs, shale shaker screens for sale from reliable shale shakerscreen manufacturers protect downstream equipment—desanders, desilters, centrifuges—by maximizing solids removal on the first pass. In water-based, synthetic-based, and oil-based mud systems, high-efficiency shale shaker screen mesh helps minimize mud losses, stabilize rheology, and lower dilution rates. Hook strip soft screens are prized for their quick changeouts, tight sealing, and uniform tension, which maintains separation efficiency during vibration. Key advantages include consistent cut point performance, strong resistance to blinding in gumbo or reactive shales, and rugged edges that stay locked during long runs. Anping County Hangshun Wire Mesh Manufacture Co., Ltd leverages deep application experience to recommend the right shale shaker screen material and mesh configuration for each formation and mud weight, supporting faster ROP recovery after connections and reducing non-productive time. For procurement teams comparing a shale shaker screen price, Hangshun’s balanced design—combining conductance, service life, and compatibility—translates into fewer screen swaps, smoother fluid returns, and measurable savings per barrel of drilled fluid.

Cost, Maintenance & User Experience

Total cost of ownership goes beyond the initial shale shaker screen price. The optimal selection lowers mud dilution, reduces disposal volumes, and decreases wear on downstream equipment. Operators report that specifying high-quality screens from a proven shale shaker screen supplier can cut screen consumption rates and reduce unplanned trips for changeouts—translating to lower per-well costs. Best practices include rotating screens by position, inspecting with a backlight for early cloth damage, promptly plugging torn cells, and avoiding excessive pressure washing that can harm the wire cloth. Proper storage in dry, flat conditions preserves adhesive integrity and hook alignment, extending usable life. Anping County Hangshun Wire Mesh Manufacture Co., Ltd provides responsive support on mesh selection and usage guidelines, helping customers realize higher ROI from each panel. From a buyer’s perspective, working directly with a shale shaker screen factory in China streamlines lead times and ensures consistent quality across batches—key for multi-rig programs. When you evaluate shale shaker screens for sale, consider not only unit price, but the impact on mud cost, disposal, rig time, and HSE risk exposure.

Sustainability & Market Trends in Oil and gas industry

Stricter environmental regulations and higher ESG expectations are reshaping solids control strategies. Efficient shale shaker screen performance reduces dilution water, lowers cuttings volumes, and minimizes drilling waste haul-off—directly improving carbon and cost profiles. Market demand is rising for durable screens built from corrosion-resistant shale shaker screen material that maintains conductance longer, cutting consumption and waste. As a forward-looking shale shaker screen china manufacturer, Anping County Hangshun Wire Mesh Manufacture Co., Ltd emphasizes material traceability, careful bonding processes, and rigorous QC to deliver consistent results across mesh ranges. In parallel, digitalization and performance benchmarking are helping B2B decision makers compare lifecycle costs across shale shaker screen suppliers and optimize fleets by well profile. Regional growth in the Middle East, North America, and Asia-Pacific underscores the need for dependable logistics and scalable production. By aligning robust engineering with responsible manufacturing practices, Hangshun supports operators and service companies in meeting both operational KPIs and sustainability goals.

Conclusion on [shale shaker screen,shale shaker screen mesh,shale shaker screen suppliers,shale shaker screen material,shale shaker screen for sale,shale shaker screen supplier,shale shaker screen factory,shale shaker screen china,shale shaker screen price,shale shakerscreen manufacturers,shale shaker screens for sale] from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

For drilling programs that demand reliable solids control, choosing the right shale shaker screen—mesh, material, and construction—drives fluid stability, lower costs, and safer operations. As an experienced shale shaker screen supplier and manufacturer, Anping County Hangshun Wire Mesh Manufacture Co., Ltd delivers consistent quality, application-driven recommendations, and competitive value. Ready to benchmark options and review shale shaker screen for sale selections for your rigs?

Contact us: email: sales@hfpetromesh.com

Visit our website: https://www.hfpetromesh.com

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025