- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Looking for API 13C Shale Shaker Screen at Factory Price?

[shale shaker screen,shale shaker screen mesh,shale shaker screen suppliers,shale shaker screen material,shale shaker screen for sale,shale shaker screen supplier,shale shaker screen factory,shale shaker screen china,shale shaker screen price,shale shakerscreen manufacturers,shale shaker screens for sale] is a key solution in the Oil and gas industry industry, specifically within Oil and gas equipment and services and Drilling solid control equipment and accessories. This article explores how Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- [shale shaker screen,shale shaker screen mesh,shale shaker screen suppliers,shale shaker screen material,shale shaker screen for sale,shale shaker screen supplier,shale shaker screen factory,shale shaker screen china,shale shaker screen price,shale shakerscreen manufacturers,shale shaker screens for sale] Overview

- Benefits & Use Cases of [shale shaker screen,shale shaker screen mesh,shale shaker screen suppliers,shale shaker screen material,shale shaker screen for sale,shale shaker screen supplier,shale shaker screen factory,shale shaker screen china,shale shaker screen price,shale shakerscreen manufacturers,shale shaker screens for sale] in Drilling solid control equipment and accessories

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Oil and gas industry

- Conclusion on [shale shaker screen,shale shaker screen mesh,shale shaker screen suppliers,shale shaker screen material,shale shaker screen for sale,shale shaker screen supplier,shale shaker screen factory,shale shaker screen china,shale shaker screen price,shale shakerscreen manufacturers,shale shaker screens for sale] from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

[shale shaker screen,shale shaker screen mesh,shale shaker screen suppliers,shale shaker screen material,shale shaker screen for sale,shale shaker screen supplier,shale shaker screen factory,shale shaker screen china,shale shaker screen price,shale shakerscreen manufacturers,shale shaker screens for sale] Overview

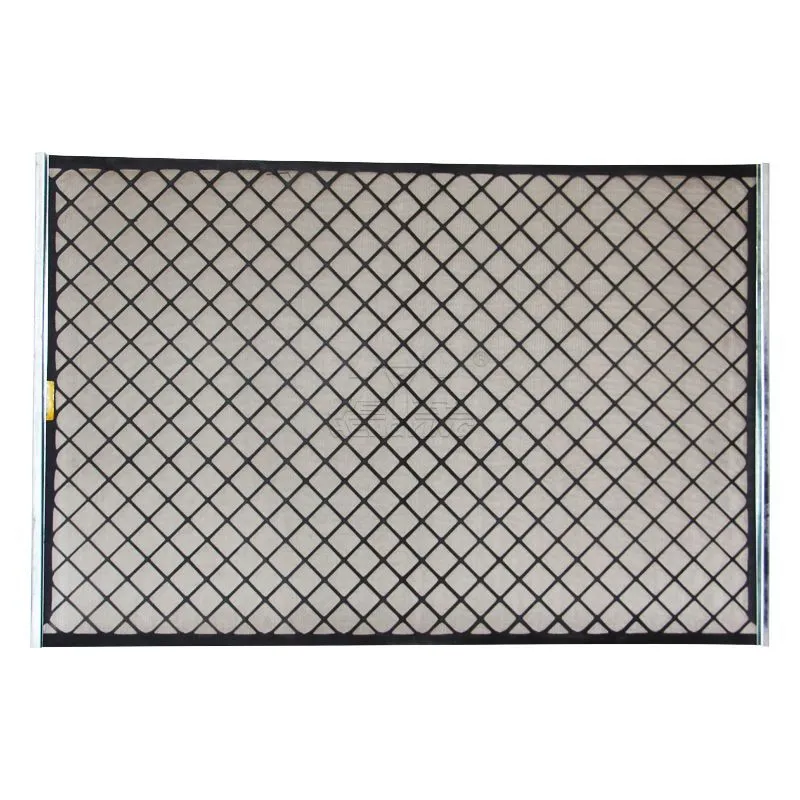

In drilling solids control, a shale shaker screen is the first line of defense for protecting drilling fluids and downstream equipment. The screen separates cuttings from mud on the shaker bed, balancing throughput, cut point, and screen life. Typical shale shaker screen mesh ranges from API 20 to API 325, with multi-layer configurations (2–3 layers) and options for hook strip soft screens or pre-tensioned panel designs. Common shale shaker screen material includes SS304/SS316 stainless steel for corrosion resistance and consistent aperture integrity.

Anping County Hangshun Wire Mesh Manufacture Co., Ltd designs and manufactures high-quality screens engineered to API RP 13C. As a specialized shale shaker screen supplier and OEM partner, the company offers standardized and custom sizes compatible with leading shaker brands. From wire diameter selection and bonding processes to enhanced open-area backing plates, Hangshun’s engineering aims to maximize solids conveyance while minimizing blinding and wear—critical for drilling contractors and service companies seeking reliable shale shaker screens for sale that support higher ROP and lower mud losses.

Benefits & Use Cases of [shale shaker screen,shale shaker screen mesh,shale shaker screen suppliers,shale shaker screen material,shale shaker screen for sale,shale shaker screen supplier,shale shaker screen factory,shale shaker screen china,shale shaker screen price,shale shakerscreen manufacturers,shale shaker screens for sale] in Drilling solid control equipment and accessories

Shale shaker screens operate at the heart of solids control trains—before desanders, desilters, and centrifuges—making their performance decisive for fluid quality and system uptime. In practical terms, optimized shale shaker screen mesh and layer combinations help operators:

- Recover more drilling fluid with consistent cut points across API 60–230 for typical oil and gas formations.

- Reduce mud dilution and chemical costs by minimizing ultrafines carryover.

- Extend equipment life by preventing oversized solids from reaching downstream assets.

Hangshun’s competitive advantages include robust hook strip soft screen construction, high open-area designs, precision-bonded multi-layer stainless steel mesh, and tight quality controls from a dedicated shale shaker screen factory. Buyers seeking a trusted shale shaker screen supplier in shale shaker screen china markets value short lead times, dimensional accuracy, and dependable gasket sealing. Compared with generic shale shakerscreen manufacturers, Hangshun emphasizes repeatable performance, rigorous QC, and tailored support—key differentiators for drilling contractors managing complex fluids and variable solids loading.

Cost, Maintenance & User Experience

Total cost of ownership depends on shale shaker screen price, service life, and fluid savings. While screen price matters, B2B decision makers typically evaluate cost per operating hour and the value of higher fluid recovery. Durable shale shaker screen material (SS304/SS316), quality adhesives, and reinforced backing reduce premature failures from vibration, abrasion, and corrosion—translating to fewer changeouts, less NPT, and improved safety exposure on the shaker deck.

Customers report that Hangshun’s screens deliver stable API cut points and long wear life across water-based and oil-based mud systems, especially when paired with proper tensioning and routine deck inspections. Best practices include cleaning screens between runs, replacing damaged gaskets promptly, and rotating panels to balance wear. For procurement teams comparing shale shaker screens for sale, Hangshun offers transparent specs, consistent supply, and technical guidance to match mesh selections with formation characteristics—helping reduce overall mud costs and enhancing ROI beyond the initial shale shaker screen price.

Sustainability & Market Trends in Oil and gas industry

Solids control directly supports ESG goals by reducing waste volumes and maximizing drilling fluid reuse. High-efficiency shale shaker screens lower disposal costs and emissions associated with transporting and treating waste cuttings. As regulations tighten and operators pursue decarbonization, screens that maintain integrity and open area under high G-force help stabilize the process, cutting dilution rates and chemical consumption.

Market trends show growing demand for API RP 13C-compliant products, traceable supply chains, and rapid customization. Anping County Hangshun Wire Mesh Manufacture Co., Ltd aligns with these trends by investing in precise mesh weaving, quality bonding, and inspection protocols at its shale shaker screen china facility. The company provides data-backed recommendations, material certifications, and flexible logistics—positioning itself as a forward-looking partner to operators, service companies, and shale shaker screen suppliers that need reliable, eco-conscious sourcing at scale.

Conclusion on [shale shaker screen,shale shaker screen mesh,shale shaker screen suppliers,shale shaker screen material,shale shaker screen for sale,shale shaker screen supplier,shale shaker screen factory,shale shaker screen china,shale shaker screen price,shale shakerscreen manufacturers,shale shaker screens for sale] from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

Optimized shale shaker screens are essential to protect fluids, equipment, and budgets across drilling programs. From precise shale shaker screen mesh selection to robust shale shaker screen material and dependable supply, Anping County Hangshun Wire Mesh Manufacture Co., Ltd delivers consistent quality and value. For buyers comparing shale shaker screen price and performance among shale shaker screen suppliers, Hangshun offers engineering support, fast delivery, and API-compliant quality.

Contact us: email: sales@hfpetromesh.com

Visit our website: https://www.hfpetromesh.com

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025