- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

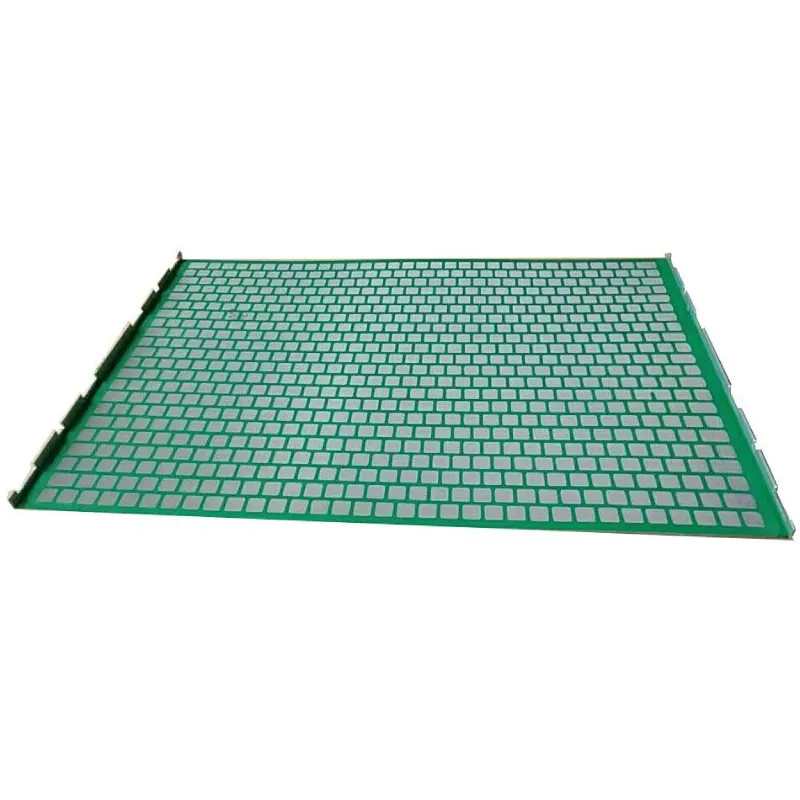

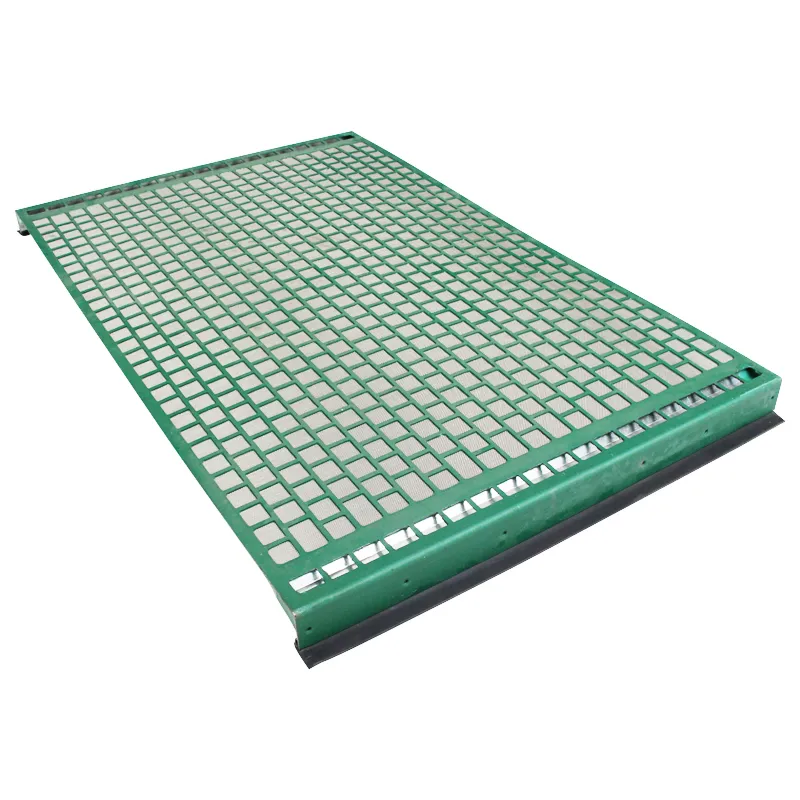

Shale Shaker Screen - Durable Mesh, Factory Price, Fast Ship

Shale Shaker Screen is a key solution in the Machinery and equipment industry, specifically within Special equipment for oil and gas and Drilling solid control equipment and accessories. This article explores how Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Shale Shaker Screen Overview

- Benefits & Use Cases of Shale Shaker Screen in Drilling solid control equipment and accessories

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Machinery and equipment

- Conclusion on Shale Shaker Screen from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

Shale Shaker Screen Overview

In drilling solids control, the Shale Shaker Screen is the first and most critical filtration stage, separating cuttings from drilling fluid to protect downstream equipment and maintain mud properties. Typically built with multi-layer stainless steel cloth (SS304/SS316) and configured as hook strip flat, pre-tensioned, or composite frame designs, these screens deliver precise cut points defined by API RP 13C. Available in a wide range of shale shaker screen mesh counts—from coarse to ultra-fine—operators can tune separation efficiency and flow capacity to match formation conditions and fluid systems.

From a technical standpoint, modern screens balance open area, conductance, and mechanical strength. Layered cloth with square or rectangular weaves, robust bonding, and anti-blinding patterns stabilizes performance under high G-force vibration. For example, consistent D100 cut points and stable conductance across a run reduce dilution rates and mud losses. As a specialized shale shaker screen factory in Anping—the wire mesh capital—Anping County Hangshun Wire Mesh Manufacture Co., Ltd leverages precision weaving, strict QC, and traceable batches to supply dependable products worldwide. As a leading source of shale shaker screen China manufacturing, the company provides reliable quality, fast lead times, and engineered screens that integrate seamlessly with common shaker models.

Benefits & Use Cases of Shale Shaker Screen in Drilling solid control equipment and accessories

Shale shaker screens are integral across land rigs, offshore platforms, workover operations, HDD/trenchless, and geothermal projects. In water-based or oil-based mud systems, the right shale shaker screen mesh improves solids removal efficiency, reduces recirculation of fines, and protects centrifuges, desanders, and desilters. For drilling contractors, accurately sized screens mean fewer unplanned trips to address gumbo, less abrasion on pumps, and improved ROP stability by maintaining mud rheology.

- High open-area cloth and consistent tensioning enhance flow while maintaining the API cut point.

- SS316 corrosion resistance and robust bonding extend life in aggressive OBM and high-temperature wells.

- Anti-blinding patterns and flatness control reduce plugging and maintain conductance over longer runs.

- Fit-for-purpose designs (hook strip flat and others) simplify change-outs and keep uptime high.

Anping County Hangshun Wire Mesh Manufacture Co., Ltd applies application-driven engineering—matching mesh counts, cloth types, and bonding systems to your formation and mud program. The result is a high-performance screen portfolio that balances separation efficiency, durability, and total cost, backed by responsive support and rapid delivery schedules.

Cost, Maintenance & User Experience

When evaluating shale shaker screen price, B2B buyers should consider total cost of ownership (TCO): screen life, separation efficiency, and the resulting mud savings. Premium cloth with stable tensioning reduces premature failures, while accurate API ratings minimize dilution and waste volumes—direct contributors to reduced mud costs. Bulk purchasing and standardized screen fleets further lower inventory overheads and freight. Hangshun offers pricing options aligned to mesh count, material (SS304 vs SS316), and order quantity, helping procurement teams optimize lifecycle value rather than unit price alone.

- Maintenance tips: store screens flat and dry, avoid UV exposure, inspect bond lines, and verify tension before installation.

- Operational best practices: select the correct shale shaker screen mesh progression, avoid over-tightening, and adjust deck angle to limit flooding or blinding.

- User feedback consistently highlights fewer change-outs, stable cut points, and predictable performance across long intervals—key for planning and cost control.

Buyers working with Anping County Hangshun Wire Mesh Manufacture Co., Ltd gain direct support from a specialized shale shaker screen factory, including technical selection guidance and fast replacement supply—minimizing non-productive time and strengthening ROI at the rig site.

Sustainability & Market Trends in Machinery and equipment

Stricter environmental regulations and ESG commitments are reshaping solids control strategies. Finer, more consistent separation reduces dilution, mud losses, and waste hauling—lowering Scope 3 impacts and disposal liabilities. The market is trending toward higher open-area meshes, improved bonding systems with reduced VOCs, and durable materials that extend service life. Digital traceability and API RP 13C compliance are increasingly required for quality assurance across global supply chains.

Positioned as a quality-driven shale shaker screen China manufacturer, Anping County Hangshun Wire Mesh Manufacture Co., Ltd invests in energy-efficient weaving, precise slitting, and optimized curing processes to reduce waste and energy consumption. Recyclable packaging and process controls further minimize environmental footprint. By pairing sustainability with performance, Hangshun enables operators to achieve both regulatory compliance and cost-effective solids control—without compromising screen longevity or API performance.

Conclusion on Shale Shaker Screen from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

For B2B decision makers in Machinery and equipment—especially Special equipment for oil and gas—high-quality Shale Shaker Screen solutions are essential to protect assets, cut mud costs, and enhance drilling performance. Anping County Hangshun Wire Mesh Manufacture Co., Ltd combines precision manufacturing, application-driven engineering, and responsive service to deliver screens with dependable API performance and long service life. As a trusted shale shaker screen factory, Hangshun offers competitive value, consistent quality, and fast delivery. Contact us: email: sales@hfpetromesh.com — Visit our website: https://www.hfpetromesh.com

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025