- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Metal Grating for Sale – Anti-Slip, Heavy-Duty, Custom Sizes

Metal Grating For Sale is a key solution in the manufacturing industry, specifically within Manufacturing of metal products and Metal structure manufacturing. This article explores how Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Metal Grating For Sale Overview

- Benefits & Use Cases of Metal Grating For Sale in Metal structure manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Metal Grating For Sale from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

Metal Grating For Sale Overview

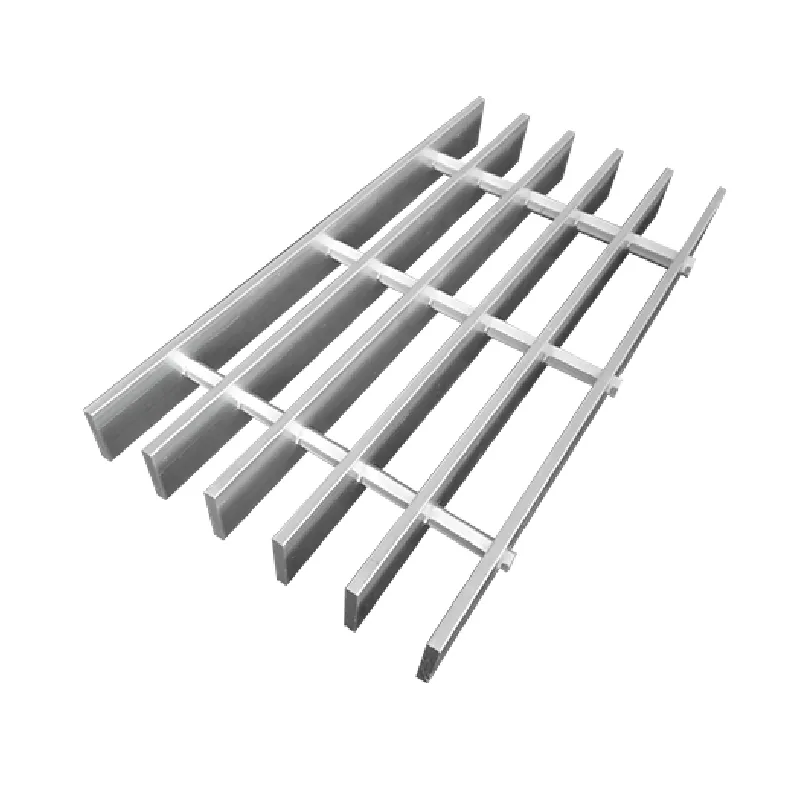

Engineered for strength, drainage, and safety, metal grating is a load-bearing panel composed of parallel bearing bars locked to transverse cross bars. Anping County Hangshun Wire Mesh Manufacture Co., Ltd specializes in swage-locked (press-locked) steel grating—precision-formed by mechanically swaging cross bars into pre-punched bearing bars to deliver tight tolerances, clean lines, and consistent load performance. Typical options include carbon steel grating in ASTM A36/A1011 material, with serrated or plain bearing bars, and hot-dip galvanized finishes to enhance corrosion resistance (commonly galvanized per ASTM A123/ISO 1461). Standard bar spacings (e.g., 30 mm, 34.3 mm, 40 mm) and cross bar spacings (50–100 mm) cover most industrial loads, while custom panel sizes and edges fit OEM fabrication workflows.

- Highly relevant to Manufacturing of metal products and Metal structure manufacturing for platforms, catwalks, mezzanines, trench covers, and stair treads.

- Technical specs include serrated anti-slip surfaces, high strength-to-weight ratios, and uniform load distribution per recognized grating guidelines (e.g., NAAMM MBG).

- As a reliable manufacturer, Hangshun supplies consistent quality, short lead times, and engineered guidance for teams seeking to buy steel grating at scale.

Benefits & Use Cases of Metal Grating For Sale in Metal structure manufacturing

In metal structure manufacturing, grating integrates seamlessly with welded frames and bolted assemblies, enabling fast installation and safe access. Common applications include industrial platforms, pipe rack walkways, access bridges, machinery maintenance decks, sump and trench covers, and stair treads where anti-slip performance and debris/liquid drainage are critical. Carbon steel grating provides an economical, robust option for high-traffic areas; stainless variants are chosen for aggressive environments. Among the types of steel grating, swage-locked stands out for clean aesthetics and dimensional accuracy, while heavy-duty and serrated profiles ensure capacity and traction.

- Competitive advantages: high strength-to-weight ratio, excellent airflow and drainage, quick field cutting, and compatibility with OSHA/ISO-driven safety designs for walkways and guardrail systems.

- Customization: bearing bar depth/thickness, serration, panel size, banding, kick plates, and hot-dip galvanizing for long-term corrosion protection.

- Hangshun’s sector expertise covers design assistance, take-offs from drawings, and bulk supply planning—streamlining procurement for B2B teams that need to buy steel grating reliably and on schedule.

Cost, Maintenance & User Experience

Total cost of ownership depends on material (carbon steel grating vs. stainless), bar size, spacing, finish, and volume. For most facilities, hot-dip galvanized carbon steel balances up-front cost with a long service life, minimizing repainting and unplanned shutdowns. The open-grid design reduces accumulation of liquids and debris, lowering cleaning frequency. With proper specification and installation, grating can deliver multi-year ROI through reduced slip incidents, fewer replacements, and fast access for maintenance teams.

- Durability: galvanizing provides sacrificial protection; serrated surfaces maintain traction under oil, moisture, and particulates.

- Maintenance: periodic visual inspections for coating condition, fastener integrity, and impact damage; straightforward panel replacement keeps downtime low.

- User feedback from Manufacturing of metal products operations often highlights improved safety on elevated platforms and the ease of integrating grating with structural steel and OEM skids.

Sustainability & Market Trends in manufacturing

Sustainability priorities are shaping how B2B buyers evaluate access systems and flooring. Steel grating aligns naturally with circular-economy goals: it is durable, repairable, and highly recyclable at end-of-life. Hot-dip galvanized finishes extend service life, reducing replacement frequency and embodied carbon over time. Market trends show growing demand for anti-slip surfaces, higher load ratings, and compliance with safety standards for walkways and platforms, along with a push for transparent sourcing and optimized nesting to reduce scrap in fabrication.

- Regulatory drivers: evolving safety norms for elevated access, guardrails, and fall protection increase the need for reliable grating solutions with documented performance.

- Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports eco-conscious procurement with durable designs, careful material utilization, and finish options that extend lifecycle—helping customers meet both safety and sustainability targets.

Conclusion on Metal Grating For Sale from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

Metal grating is a proven, high-ROI choice for manufacturing, Manufacturing of metal products, and Metal structure manufacturing—delivering safety, durability, and easy integration into structural steel systems. With options across types of steel grating, including cost-effective carbon steel grating and corrosion-resistant finishes, Hangshun provides dependable quality and support from design to delivery.

- Partner with a manufacturer known for precision, consistency, and responsive lead times.

- Contact us: email: sales@hfpetromesh.com

- Visit our website: https://www.hfpetromesh.com

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025