- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

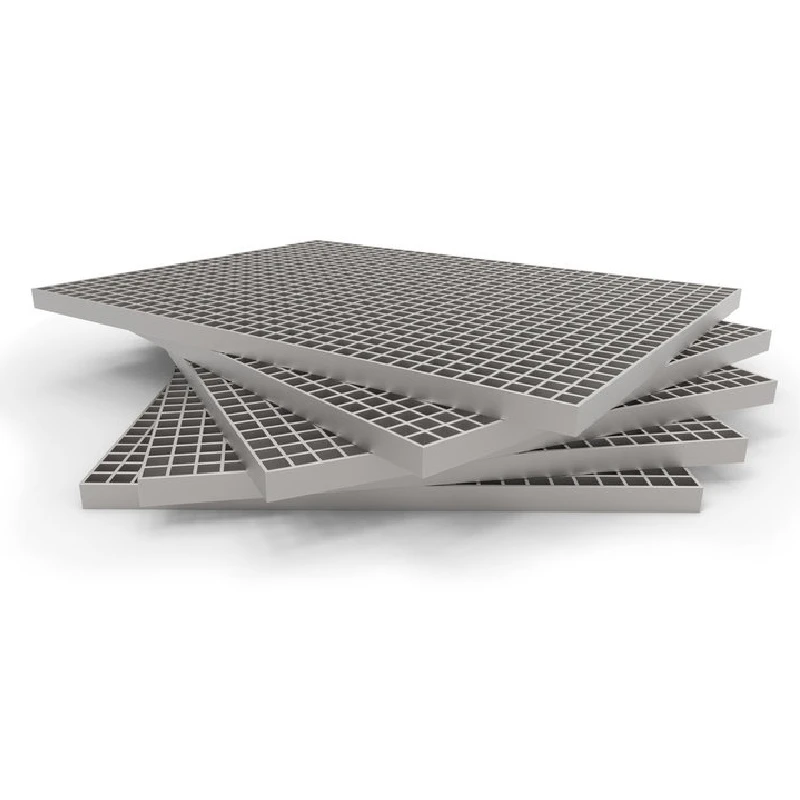

Heavy Duty Serrated Steel Grating - Anti-Slip & Durable Solutions

Understanding Serrated Steel Grating: A Critical Component for Industrial Safety and Performance

In demanding industrial environments, the selection of robust and safe flooring solutions is paramount. Serrated steel grating stands out as a superior choice, engineered specifically to address the challenges of slip hazards while providing exceptional load-bearing capabilities. This pressed-locked grating type, characterized by its notched bearing bars, delivers unparalleled traction, making it indispensable for walkways, platforms, and mezzanines in sectors where moisture, grease, oil, or other slippery substances are prevalent. Its design not only enhances worker safety but also contributes to the longevity and structural integrity of industrial infrastructure, ensuring operational continuity and compliance with stringent safety regulations.

Current Industry Trends and Market Demands

The industrial grating market is experiencing a significant shift, driven by an increased focus on worker safety, stricter environmental regulations, and the need for more durable and sustainable materials. Key trends include:

- Enhanced Safety Standards: There's a growing demand for grating solutions that actively mitigate slip and fall risks, propelling the adoption of products like serrated steel grating. Standards such as OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute) are constantly evolving, requiring manufacturers to innovate.

- Sustainability and Lifecycle Cost: Industries are increasingly evaluating products based on their total lifecycle cost, including durability, maintenance, and recyclability. Grating with extended service life and corrosion resistance, often achieved through hot-dip galvanization or the use of stainless steel, is highly favored.

- Customization and Modular Solutions: Modern industrial projects often require bespoke grating designs to fit unique structural layouts, load requirements, and access points. Manufacturers offering advanced customization, including precise cuts, banding, and special finishes, are gaining a competitive edge.

- Automation and Efficiency in Manufacturing: Advances in CNC machining and automated welding processes are leading to more precise, consistent, and cost-effective grating production, impacting overall `heavy duty steel grating price` structures.

- Demand for Heavy-Duty Applications: Sectors like mining, heavy manufacturing, and energy require grating capable of withstanding extreme loads and harsh conditions. This drives the market for `heavy duty steel grating` and `heavy duty mild steel grating` engineered for superior strength and resilience.

These trends underscore the importance of selecting a grating solution that not only meets immediate functional requirements but also aligns with long-term operational efficiency and safety goals.

Manufacturing Process of Press-Locked Serrated Steel Grating

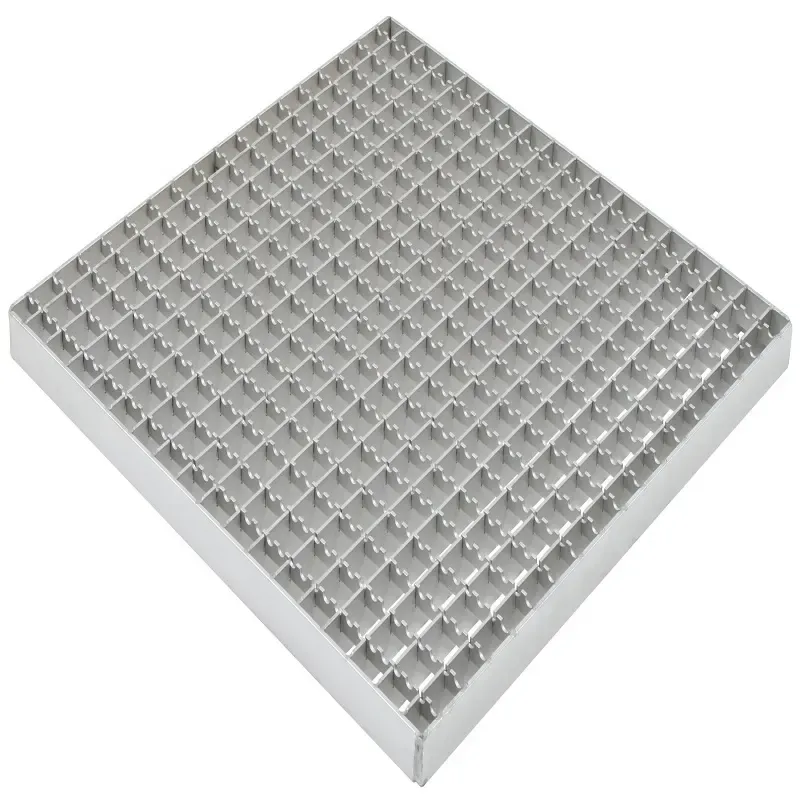

The production of high-quality serrated steel grating, particularly the press-locked variant, is a precision-driven process that ensures structural integrity, uniform serration, and consistent performance. This method relies on hydraulic pressure to permanently join bearing bars and cross bars without welding, creating a robust and aesthetically pleasing grid.

Process Flow:

- Material Selection and Preparation:

- Materials: Typically high-strength mild steel (e.g., ASTM A36, Q235, S275JR), stainless steel (e.g., SS304, SS316, SS316L), or sometimes aluminum alloys. The choice depends on the required load capacity, corrosion resistance, and specific environmental conditions.

- Slitting: Large steel sheets or coils are precisely cut into strips of specific widths and thicknesses, which will become the bearing bars and cross bars.

- Serration: The top edge of the bearing bars is precisely notched or serrated using specialized machinery to create the anti-slip surface. This is a critical step for serrated steel grating.

- Notching (Slotting) of Bearing Bars:

- Bearing bars are slotted at regular intervals to allow for the insertion of cross bars. The slots are precisely sized to create an interference fit.

- Press-Locking (Interlocking):

- The notched cross bars are pressed into the slotted bearing bars under extreme hydraulic pressure. This forms a tight, permanent mechanical interlock. This method ensures high structural rigidity and a clean aesthetic.

- Trimming and Edging:

- The assembled grating panels are trimmed to the specified dimensions. Edging, or banding, is applied along the perimeter for enhanced load distribution and improved aesthetics, particularly for `heavy duty steel grating`.

- Surface Treatment:

- Hot-dip Galvanizing: This is the most common and effective treatment for `mild steel grating` and `heavy duty mild steel grating`, providing excellent corrosion resistance. The grating is immersed in molten zinc, creating a metallurgical bond that protects the steel for decades, ensuring a long service life.

- Painting/Powder Coating: Applied for specific color requirements or additional protection in less corrosive environments.

- Mill Finish: For stainless steel grating where inherent corrosion resistance is sufficient.

- Quality Control and Testing:

- Every batch undergoes rigorous inspection for dimensional accuracy, panel flatness, serration consistency, and coating thickness. Testing standards typically adhere to international specifications such as ISO 9001 (Quality Management Systems), ANSI/NAAMM MBG 531 (Metal Bar Grating Manual), and ASTM A123/A123M (Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products). Load-bearing tests are conducted to ensure compliance with specified design loads and deflection limits, confirming the product's suitability for target industries like petrochemical, metallurgy, and water supply & drainage. The service life often exceeds 20-30 years with proper galvanization in typical industrial settings.

This meticulous process ensures that the final serrated steel grating product offers not only superior slip resistance but also exceptional strength and durability, contributing to energy saving through reduced maintenance and replacement costs, and outstanding corrosion resistance.

Technical Specifications and Parameters

The performance of serrated steel grating is defined by several key technical parameters, which are crucial for engineers and decision-makers during the specification process. Understanding these elements ensures the selection of the correct grating for specific load requirements, environmental conditions, and safety needs.

Key Technical Terminology:

- Bearing Bar: The primary load-carrying bar, running in the direction of the span. Its dimensions (height x thickness) and material determine the grating's load capacity and deflection.

- Cross Bar: The secondary bar, running perpendicular to the bearing bars, typically press-locked into position. It provides lateral stability and helps distribute loads.

- Bar Spacing (Pitch): Refers to the center-to-center distance between bearing bars and cross bars. Common pitches are 30mm, 40mm for bearing bars, and 50mm, 100mm for cross bars.

- Open Area: The percentage of the grating surface that is open, allowing for light, air, and liquid passage. Higher open area reduces weight but can affect strength.

- Load Deflection: The amount of bending under a specified load. This is a critical factor for safety and comfort, often governed by local building codes and design standards.

- Shear Strength: The grating's ability to resist forces parallel to its surface, particularly relevant in applications with high lateral loads.

- Slip Resistance Coefficient: A quantifiable measure of the friction provided by the serrated surface, ensuring enhanced safety in wet or oily conditions.

Typical Product Specifications for Press-Locked Serrated Steel Grating:

| Parameter | Specification Range / Standard | Notes |

|---|---|---|

| Material Grade | Mild Steel (Q235, ASTM A36, S275JR), Stainless Steel (SS304, SS316, SS316L) | Corrosion resistance & strength |

| Bearing Bar Size (Height x Thickness) | 25x3mm to 100x10mm (1"x1/8" to 4"x3/8") | Load capacity & span capability. Defines `heavy duty steel grating` options. |

| Bearing Bar Pitch | 30mm, 32.5mm, 35mm, 40mm, 50mm (1-3/16", 1-1/4", 1-1/2", 2") | Impacts open area & load distribution |

| Cross Bar Pitch | 50mm, 100mm (2", 4") | Lateral stability & support |

| Surface Treatment | Hot-dip Galvanized (ASTM A123/A123M), Electro-Galvanized, Painted, Mill Finish | Corrosion protection & aesthetics. Especially crucial for `mild steel grating`. |

| Load Capacity (e.g., for 1000mm span) | Varies significantly by bar size and pitch. E.g., 40x5mm bearing bar can support ~15 kN/m² | Engineered to meet specific project demands. |

| Service Life | 20-30+ years (hot-dip galvanized mild steel) | Dependent on environmental conditions & maintenance. |

These specifications are crucial for ensuring that the chosen serrated steel grating meets the structural and safety requirements of any industrial application, providing a reliable and long-lasting solution.

Application Scenarios for Serrated Steel Grating

The robust construction and superior anti-slip properties of serrated steel grating make it an ideal choice for a wide array of demanding industrial applications where safety, durability, and reliable performance are paramount. Its versatility allows it to be deployed across various critical sectors.

Target Industries:

- Petrochemical and Oil & Gas: For offshore platforms, refineries, and chemical processing plants where oil, grease, and hazardous liquids can create slippery surfaces.

- Power Plants: Especially in areas around boilers, turbines, and cooling towers, providing safe access in potentially wet or steamy environments.

- Metallurgy and Mining: In smelting plants, mining operations, and mineral processing facilities where dust, ore, and lubricants are common. This often requires `heavy duty steel grating`.

- Water Supply & Drainage / Wastewater Treatment: For access ways over sumps, tanks, and filtration units where constant moisture and corrosive elements are present.

- Marine and Shipbuilding: For decks, gangways, and engine rooms where slip resistance is critical due to constant exposure to water and oils.

- Food & Beverage Processing: In wash-down areas, ensuring hygienic and safe working conditions.

- Heavy Manufacturing: For elevated walkways, production line platforms, and maintenance access in facilities dealing with heavy machinery and industrial lubricants.

Typical Application Scenarios:

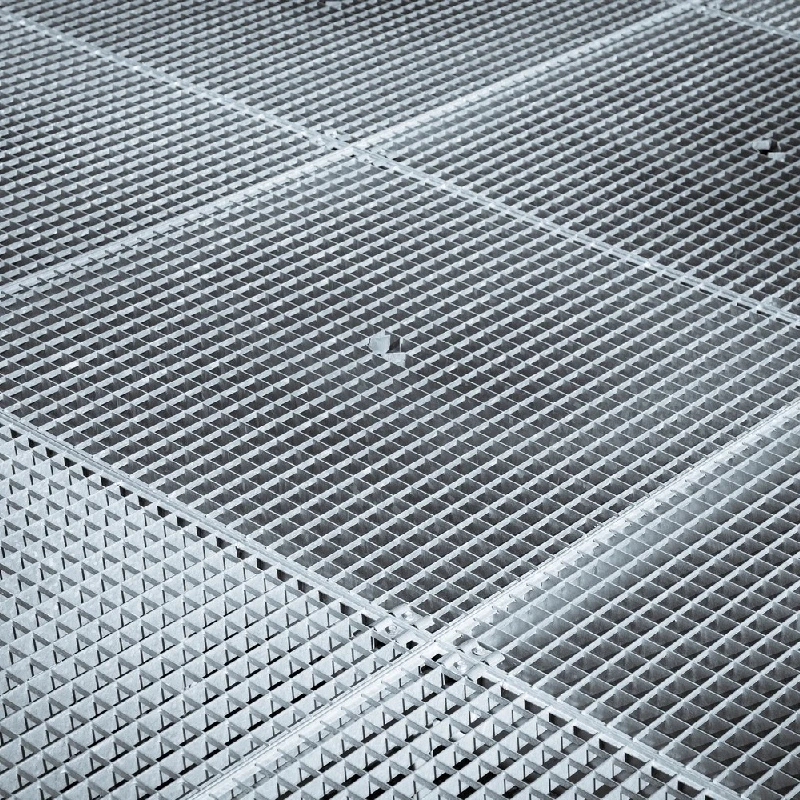

- Industrial Walkways and Platforms: Essential for safe pedestrian and vehicular traffic in factory floors, processing areas, and utility corridors.

- Stair Treads: Provides crucial grip on industrial staircases, preventing slips during ascent and descent, particularly in high-traffic or emergency exit routes.

- Trench Covers: Safely covers open trenches, sumps, and drains, allowing for proper drainage while maintaining safe passage.

- Mezzanines and Catwalks: Offers a secure elevated surface for operational access and storage, maximizing floor space.

- Vehicle and Equipment Ramps: Ideal for providing traction for wheeled vehicles or heavy equipment, especially on inclines.

In each of these scenarios, the inherent advantages of serrated steel grating, such as its robust corrosion resistance (especially when hot-dip galvanized) and significant energy saving potential through reduced maintenance and improved operational safety, are fully realized. This makes it an invaluable asset for any facility prioritizing safety and long-term performance.

Technical Advantages and Performance Benefits

The distinctive design of serrated steel grating confers a range of significant technical advantages that elevate its performance above standard grating types, particularly in challenging industrial settings.

Key Advantages:

- Superior Slip Resistance: The most prominent advantage. The serrated edges of the bearing bars provide aggressive traction, dramatically reducing the risk of slips and falls, even when surfaces are wet, oily, icy, or contaminated with industrial debris. This directly translates to enhanced worker safety and fewer workplace accidents.

- High Strength-to-Weight Ratio: Despite its robust construction, steel grating, including `heavy duty steel grating`, offers excellent load-bearing capabilities relative to its weight. This optimizes structural design, potentially reducing the need for heavier supporting structures and associated costs.

- Exceptional Durability and Longevity: Manufactured from high-grade steel and often finished with hot-dip galvanization, serrated steel grating is highly resistant to wear, impact, and fatigue. This ensures a long service life, minimizing replacement and maintenance costs over the facility's lifespan.

- Corrosion Resistance: For `mild steel grating`, hot-dip galvanizing creates a durable zinc coating that offers superior protection against rust and corrosion in harsh, corrosive environments, such as those found in chemical plants or coastal facilities. Stainless steel options further enhance this resistance.

- Ease of Installation and Maintenance: Grating panels are typically prefabricated to specific dimensions, allowing for quick and straightforward installation using various clamping methods. The open-grid design facilitates drainage, airflow, and light penetration, reducing debris accumulation and simplifying cleaning procedures, thereby contributing to overall energy saving in operations.

- Versatility: Available in a wide range of bearing bar sizes, pitches, and material grades, including options for `heavy duty mild steel grating`, it can be customized to meet diverse load requirements and functional needs.

These combined technical advantages underscore why serrated steel grating is a preferred choice for critical industrial infrastructure, offering a blend of safety, strength, and economic efficiency that few other flooring materials can match. Its contribution to reducing operational risks and extending asset life makes it a highly valuable investment.

Vendor Comparison and Selection Criteria

When procuring serrated steel grating, selecting the right vendor is as crucial as specifying the right product. B2B decision-makers should evaluate potential suppliers based on a comprehensive set of criteria to ensure quality, reliability, and long-term value. This involves looking beyond just the `heavy duty steel grating price`.

Key Factors for Vendor Evaluation:

- Quality Certifications & Standards: A reputable vendor will hold certifications such as ISO 9001 (Quality Management System) and ensure their products comply with industry standards like ANSI/NAAMM MBG 531, ASTM A123 (for galvanization), and relevant regional building codes. These certifications are a hallmark of authoritativeness and commitment to quality.

- Manufacturing Capabilities: Assess the vendor's production capacity, technology (e.g., advanced press-locking machinery, CNC cutting), and quality control processes. This directly impacts product precision, consistency, and ability to handle large orders.

- Customization Options: Evaluate the vendor's flexibility in offering tailored solutions—different materials (e.g., `mild steel grating`, stainless steel), sizes, load capacities, cutouts, and banding options. This is essential for projects with unique design requirements.

- Technical Support and Expertise: A strong vendor provides knowledgeable technical assistance, design guidance, and engineering support to help specify the correct grating for complex applications. Look for evidence of deep industry expertise and years of service.

- Lead Time and Fulfillment Reliability: In project-driven industries, timely delivery is critical. Investigate the vendor's typical lead times, production scheduling transparency, and logistics capabilities.

- After-Sales Service and Warranty: Understand the warranty offered, customer support channels, and responsiveness to post-delivery inquiries or issues. A strong warranty commitment signifies trustworthiness.

- Project Portfolio & References: Review the vendor's track record, especially in projects similar to yours. Customer feedback and details of past service cases offer valuable insights into their experience and reliability. Many leading companies partner with vendors with proven track records.

By thoroughly vetting vendors against these criteria, decision-makers can confidently select a partner capable of delivering high-quality serrated steel grating solutions that meet specific project demands and contribute to long-term operational success.

Customized Solutions for Specialized Applications

While standard serrated steel grating offers broad utility, many industrial projects necessitate bespoke solutions to perfectly integrate with existing structures, accommodate unique load requirements, or address specific environmental challenges. Customization ensures optimal performance, safety, and cost-efficiency.

Areas of Customization:

- Material Grade: Beyond standard `mild steel grating` (Q235, ASTM A36) and SS304/SS316 stainless steel, specific projects might require specialized alloys for extreme chemical resistance or high-temperature applications.

- Bearing Bar Configuration: Custom heights and thicknesses of bearing bars can be engineered to precisely match specific span lengths and required load capacities, including options for `heavy duty steel grating` designed for exceptional loads.

- Bar Spacing (Pitch): While standard pitches are common, custom spacing can be provided to meet specific open area requirements for drainage, light penetration, or to prevent small objects from falling through.

- Panel Dimensions and Shapes: Grating panels can be fabricated to exact dimensions, including irregular shapes, curves, and circular sections, to fit complex architectural or structural designs.

- Cutouts and Penetrations: Precise cutouts for pipes, columns, equipment bases, and other obstructions can be factory-fabricated, minimizing on-site cutting and ensuring a perfect fit.

- Surface Finishes: Beyond standard hot-dip galvanizing, options include specialized coatings, primers, or specific paint colors to match aesthetic requirements or provide additional protection against unique corrosive agents.

- Banding and Nosing: Custom banding along the perimeter and specialized nosing for stair treads enhance structural integrity and safety, particularly for `heavy duty mild steel grating` applications.

- Attachment Methods: Custom clips, anchors, or welded connections can be integrated into the design to facilitate specific installation requirements.

Partnering with a manufacturer capable of delivering these tailored solutions ensures that the serrated steel grating integrates seamlessly into the project, providing optimal performance and adherence to all operational and safety specifications.

Application Case Studies

Real-world applications demonstrate the critical role of serrated steel grating in enhancing safety and operational efficiency across diverse industrial sectors.

Case Study 1: Petrochemical Refinery Walkways

- Challenge: An aging petrochemical refinery required replacement of its platform and walkway grating. The existing smooth grating became highly hazardous due to frequent spills of oil, grease, and chemical liquids, leading to multiple slip-and-fall incidents. The environment was highly corrosive.

- Solution: Approximately 5,000 square meters of hot-dip galvanized serrated steel grating (bearing bars: 40x5mm, pitch: 30mm) were installed. The choice of `heavy duty mild steel grating` with a hot-dip galvanized finish provided both the necessary load capacity for heavy foot traffic and equipment, as well as robust corrosion resistance against the harsh chemical atmosphere.

- Outcome: Post-installation, reported slip-and-fall incidents plummeted by over 85% within the first year. The enhanced traction significantly improved worker safety and confidence. The galvanization ensured a projected service life exceeding 25 years, reducing future maintenance costs and validating the `heavy duty steel grating price` as a long-term investment.

Case Study 2: Municipal Wastewater Treatment Plant

- Challenge: A large municipal wastewater treatment facility needed durable and safe flooring for its aeration tanks and filtration units. The constant presence of water, chemical aerosols, and organic sludge created extremely slippery conditions for maintenance personnel.

- Solution: Stainless steel serrated steel grating (SS316, bearing bars: 30x3mm, pitch: 40mm) was custom-fabricated for walkways and trench covers. The inherent corrosion resistance of SS316 was critical for combating the aggressive chemical environment, and the serrated surface provided essential anti-slip properties.

- Outcome: The installation resulted in a dramatic improvement in safety for workers accessing maintenance areas. The `mild steel grating` alternative would not have offered sufficient corrosion resistance, demonstrating the importance of material selection. The durability of the stainless steel grating ensured minimal maintenance and long-term structural integrity, supporting continuous operation of the vital public infrastructure.

Product Comparison: Serrated vs. Plain Steel Grating

Choosing between serrated and plain steel grating is a crucial decision based on the specific requirements of an application. While both offer robust load-bearing capabilities, their surface characteristics dictate their suitability for different environments. This comparison table highlights key differentiators:

| Feature | Serrated Steel Grating | Plain Steel Grating |

|---|---|---|

| Slip Resistance | Excellent due to notched bearing bar edges. High coefficient of friction. Essential for oily, wet, or icy conditions. | Moderate to low. Suitable for dry environments. Can be slippery when wet or oily. |

| Typical Applications | Oil & gas, chemical plants, food processing, marine, power plants, heavy manufacturing (e.g., where `heavy duty steel grating` is needed for safety). | General industrial floors, mezzanines, architectural applications, dry storage areas where slip hazards are minimal. |

| Cost Implications | Slightly higher `heavy duty steel grating price` due to additional manufacturing step for serration, but justifiable by enhanced safety. | Generally more economical. |

| Cleaning & Maintenance | Similar to plain grating, but serrations might trap fine debris more easily. Open design facilitates cleaning. | Easy to clean, open design. |

| Aesthetics | Robust, industrial look. | Clean, uniform appearance. |

| Material Options | Available in `mild steel grating`, stainless steel, and other alloys, often hot-dip galvanized for corrosion resistance. | Available in `mild steel grating`, stainless steel, and other alloys, often hot-dip galvanized. |

For environments where safety from slips and falls is a primary concern, the investment in serrated steel grating is overwhelmingly justified, offering superior protection and compliance with stringent safety regulations.

Frequently Asked Questions (FAQ)

- Q1: What is the primary advantage of serrated steel grating?

- A1: Its primary advantage is superior slip resistance, provided by the notched edges of the bearing bars. This is crucial for safety in environments prone to moisture, oil, grease, or ice, significantly reducing the risk of slips and falls compared to plain grating.

- Q2: What materials are available for serrated steel grating?

- A2: Common materials include `mild steel grating` (e.g., ASTM A36, Q235, S275JR), which is typically hot-dip galvanized for corrosion protection, and various grades of stainless steel (e.g., SS304, SS316, SS316L) for highly corrosive or hygienic environments. `Heavy duty mild steel grating` is also a common variant.

- Q3: How is load capacity determined for `heavy duty steel grating`?

- A3: Load capacity is primarily determined by the dimensions of the bearing bars (height and thickness), the span length, and the spacing between bearing bars. Engineering calculations and load testing, often adhering to standards like ANSI/NAAMM MBG 531, are used to specify the correct grating for a given load requirement.

- Q4: What is the typical lead time for custom serrated steel grating orders?

- A4: Lead times can vary depending on order complexity, volume, material availability, and current production schedules. Standard orders typically range from 3-6 weeks, while highly customized or large-volume projects may require 6-10 weeks. Expedited options may be available upon request.

- Q5: What certifications should I look for when selecting a grating supplier?

- A5: Key certifications include ISO 9001 for quality management, ensuring consistent manufacturing processes. Product adherence to standards like ASTM A123 (for hot-dip galvanizing) and ANSI/NAAMM MBG 531 (for metal bar grating) demonstrates compliance with industry best practices and product performance specifications.

Lead Time, Warranty, and Customer Support

We understand that reliable fulfillment and comprehensive support are critical for B2B procurement of industrial products like serrated steel grating. Our commitment extends beyond product delivery to ensure peace of mind and operational continuity for our clients.

Lead Time & Fulfillment:

- Standard Orders: Typically 3-5 weeks from order confirmation, depending on specifications and quantity.

- Custom & Large Volume Orders: Estimated lead times are provided on a project-specific basis, usually ranging from 6-10 weeks, to accommodate specialized fabrication and logistics.

- Logistics: We collaborate with trusted logistics partners to ensure timely and secure delivery to your site, with detailed tracking available.

Warranty Commitments:

- Manufacturer's Warranty: All our serrated steel grating products come with a standard manufacturer's warranty against defects in materials and workmanship. This ensures confidence in the quality and durability of your investment.

- Galvanization Warranty: Hot-dip galvanized products are often backed by extended warranties specific to the galvanization coating's performance, guaranteeing long-term corrosion resistance in specified environments.

- Detailed warranty information is provided with every quotation and order.

Customer Support & After-Sales Service:

- Dedicated Technical Support: Our team of experienced engineers and product specialists is available to provide expert advice, design assistance, and technical specifications tailored to your project.

- Installation Guidance: We offer comprehensive guidance on proper installation techniques and best practices to maximize the performance and longevity of the grating.

- Responsive Inquiry Handling: Our customer service team is committed to prompt and efficient resolution of any queries or concerns, ensuring a smooth project experience from initial consultation to post-installation support.

Our dedication to quality products, reliable delivery, and robust customer support underscores our commitment to being a trusted partner in your industrial infrastructure projects.

References

- American National Standards Institute / National Association of Architectural Metal Manufacturers (ANSI/NAAMM). (2009). Metal Bar Grating Manual (MBG 531).

- ASTM International. (2015). ASTM A123/A123M - Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems — Requirements.

- Occupational Safety and Health Administration (OSHA). (2016). 29 CFR Part 1910 - Walking-Working Surfaces and Personal Fall Protection Systems.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025