- Iðnaðarsvæði, suður af Anping Town, Hengshui, Hebei, Kína.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Enska

Enska  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Enska

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

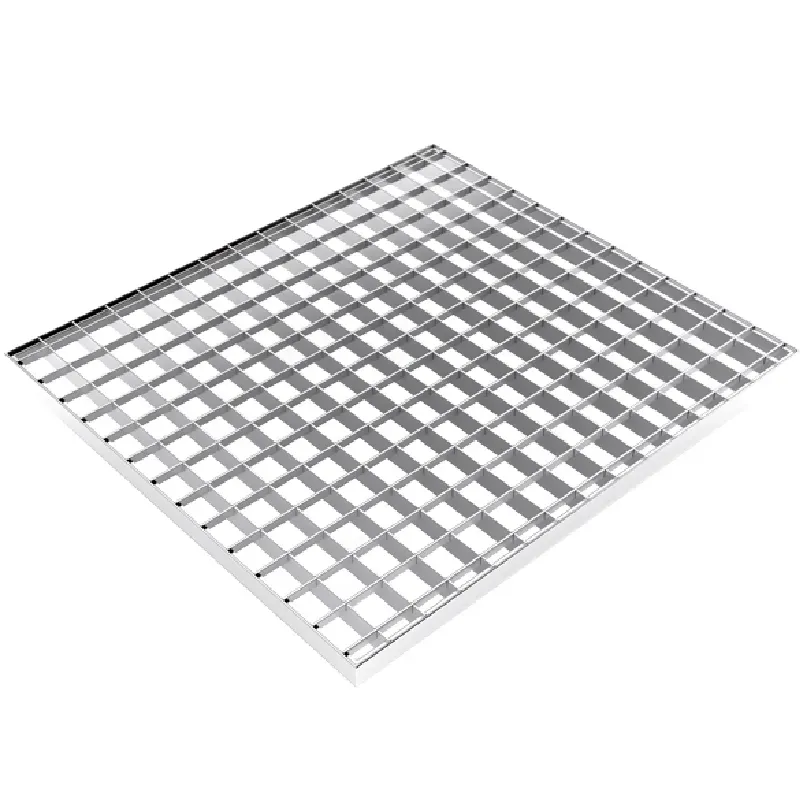

Elevating Industrial And Commercial Spaces With Durable Floor Grating Solutions

In the realm of construction and infrastructure design, selecting the right flooring materials is crucial for ensuring safety, functionality, and longevity. Among the top choices for industrial, commercial, and even residential applications are floor grating panels, galv grating, floor grating steel, floor metal grating, and flooring grating. These solutions offer a blend of strength, versatility, and aesthetic appeal, making them indispensable in various settings, from factories and warehouses to walkways and outdoor decks.

The Versatility and Strength of Floor Grating Panels

Floor grating panels are engineered to withstand heavy loads while providing excellent drainage and ventilation. Commonly used in industrial environments like factories and wastewater treatment plants, these panels are designed to handle the movement of machinery and foot traffic without compromising structural integrity. For example, in a manufacturing facility, floor grating panels can be installed in areas prone to spills, allowing liquids to drain away while supporting the weight of forklifts and other equipment. Their open - grid design also reduces the accumulation of debris, making them easier to clean and maintain compared to solid flooring options.

The Corrosion - Resistant Advantage of Galv Grating

Galv grating, short for galvanized grating, offers superior protection against rust and corrosion, making it ideal for outdoor or high - moisture environments. The galvanization process involves coating the grating with a layer of zinc, which acts as a barrier against water, salt, and other corrosive elements. This makes galv grating a popular choice for coastal walkways, parking garages, and agricultural facilities. In a marine setting, for instance, galv grating can be used to construct docks and piers, ensuring that the flooring remains durable even when exposed to constant moisture and harsh weather conditions.

The Robustness of Floor Grating Steel

Floor grating steel is a cornerstone of heavy - duty flooring solutions. Made from high - quality steel, these gratings are known for their exceptional strength and durability. In warehouses and logistics centers, floor grating steel is often used to create mezzanine floors or elevated walkways, capable of supporting large storage racks and the movement of pallet jacks. The steel can be welded or pressed to form a grid pattern, with options for different bar spacing to meet specific load - bearing requirements. This type of grating is also fire - resistant, adding an extra layer of safety in industrial settings.

The Aesthetic and Functional Appeal of Floor Metal Grating

Floor metal grating combines the strength of metal with design flexibility, making it suitable for both industrial and architectural applications. In commercial buildings, such as shopping centers or office complexes, floor metal grating can be used to create stylish walkways or stair treads, adding a modern touch to the space. The metal can be finished in various ways, such as powder - coating or painting, to match the overall aesthetic. Additionally, floor metal grating is lightweight compared to concrete or solid metal flooring, making it easier to install and transport.

The Practicality of Flooring Grating in Diverse Settings

Flooring grating is a broad category that encompasses various types of grating solutions, each tailored to specific needs. In residential applications, it can be used to create decking or patio flooring, providing a slip - resistant surface that allows water to drain quickly. For outdoor staircases, flooring grating ensures safety by preventing the accumulation of snow and ice. In agricultural settings, it is used in barns and livestock areas to facilitate waste management, as the open grid design allows manure and other debris to fall through, making cleaning more efficient.

FAQ: Key Considerations for Floor Grating Solutions

How to choose the right floor grating for my project?

Selecting the appropriate grating depends on factors such as load requirements, environment, and aesthetic goals. For heavy - duty industrial use, prioritize floor grating steel or floor metal grating with a dense grid pattern. In corrosive environments, galv grating is essential. For decorative purposes, explore floor grating panels or floor metal grating with custom finishes.

What maintenance is required for galvanized grating?

Galv grating requires minimal maintenance due to its corrosion - resistant coating. Regularly inspect for debris and clean with a mild detergent and water as needed. Avoid using abrasive tools that could damage the zinc layer.

Can floor grating panels be customized for specific sizes?

Yes, most manufacturers offer floor grating panels in custom sizes to fit unique project requirements. This includes cutting panels to size and creating custom shapes for corners or irregular spaces.

Is floor metal grating suitable for outdoor use?

Yes, floor metal grating is highly suitable for outdoor use, especially when galvanized or treated with a protective finish. It can withstand weather conditions, UV exposure, and heavy foot traffic.

How does flooring grating improve safety in industrial settings?

Flooring grating enhances safety by providing a slip - resistant surface, improving drainage to prevent water accumulation, and offering visibility through the open grid design. In high - risk areas, it also reduces the risk of tripping and allows for quick identification of hazards beneath the surface.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingFréttirNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedFréttirNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedFréttirNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMFréttirNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipFréttirNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipFréttirNov.10,2025