- Iðnaðarsvæði, suður af Anping Town, Hengshui, Hebei, Kína.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Enska

Enska  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Enska

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

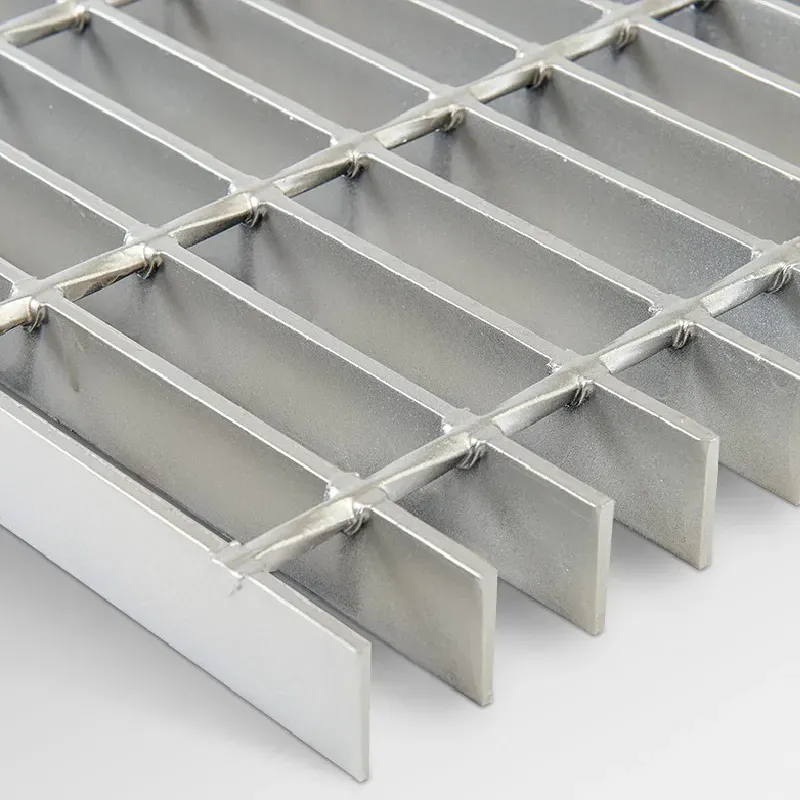

Durable and Versatile Solutions in Industrial Flooring: Galvanized Grating Systems

In the realm of industrial and commercial infrastructure, flooring solutions must balance strength, safety, and functionality. Galvanized grating systems, including galvanized serrated grating, grating galv iron, grating galvanized steel, grating hot dip galvanized, and galvanised walkway panels, have emerged as top choices for their corrosion resistance, load - bearing capacity, and adaptability across diverse environments. These products combine the robustness of metal with the protective benefits of galvanization, ensuring long - term performance in even the harshest conditions.

The Advantages of Galvanized Serrated Grating

Galvanized serrated grating stands out for its enhanced safety features, particularly in slippery environments. The serrated surface creates a textured grip, reducing the risk of slips and falls in areas exposed to moisture, oil, or debris. This type of grating is commonly used in industrial kitchens, manufacturing facilities, and outdoor walkways where traction is critical. The galvanization process, which coats the steel with a layer of zinc, adds the benefit of corrosion resistance, making galvanized serrated grating suitable for both indoor and outdoor applications. For example, in food processing plants, where frequent cleaning and wet conditions are the norm, this grating maintains its integrity while providing a secure surface for workers.

The Reliability of Grating Galv Iron

Grating galv iron, or galvanized iron grating, offers a cost - effective and durable flooring solution. Iron grating is known for its strength and ability to withstand heavy loads, making it ideal for industrial settings such as warehouses, loading docks, and vehicle repair shops. The galvanization process protects the iron from rust and oxidation, extending its lifespan even in corrosive environments. Unlike other materials, grating galv iron requires minimal maintenance, only needing occasional cleaning to remove debris. This makes it a practical choice for businesses looking for a low - upkeep flooring option that doesn’t compromise on performance.

The Strength and Versatility of Grating Galvanized Steel

Grating galvanized steel is a cornerstone of industrial flooring, valued for its high tensile strength and resistance to wear and tear. Steel grating is available in various designs, including bar grating and mesh grating, each tailored to specific load requirements and aesthetic preferences. The galvanization of steel adds an extra layer of protection, making grating galvanized steel suitable for use in coastal areas, chemical plants, and other environments where exposure to salt, acids, or other corrosive agents is a concern. Its versatility also extends to architectural applications, where it can be used for stair treads, balconies, and decorative fencing, combining functionality with a modern look.

The Superior Protection of Grating Hot Dip Galvanized

Grating hot dip galvanized undergoes a specialized galvanization process where the steel is submerged in a bath of molten zinc, creating a thick, uniform coating. This method provides superior corrosion resistance compared to other galvanization techniques, making it ideal for long - term outdoor use and high - risk environments. Hot dip galvanized grating is commonly found in oil and gas facilities, wastewater treatment plants, and offshore platforms, where exposure to harsh elements is constant. The process not only protects the surface of the grating but also penetrates the pores of the steel, ensuring complete coverage and maximum durability. As a result, grating hot dip galvanized offers one of the longest service lives among industrial flooring solutions.

The Practicality of Galvanised Walkway Panels

Galvanised walkway panels are designed for quick and easy installation, making them a popular choice for temporary or permanent walkways in construction sites, event venues, and industrial complexes. These panels feature a galvanized finish that protects against rust and ensures they can withstand heavy foot traffic and light vehicle loads. The interlocking design of galvanised walkway panels allows for rapid deployment, reducing installation time and labor costs. They are also lightweight and portable, making them easy to transport and reuse in different locations. Whether used as a safe passageway around construction equipment or as a temporary floor for outdoor events, these panels offer a reliable and versatile solution.

FAQ: Key Questions About Galvanized Grating Systems

How does galvanization protect grating from corrosion?

Galvanization coats the metal surface with a layer of zinc, which acts as a sacrificial barrier. When the grating is exposed to moisture or oxygen, the zinc corrodes instead of the underlying steel, preventing rust from forming on the metal. This is particularly effective for galvanized serrated grating, grating galvanized steel, and other galvanized products, ensuring they remain functional in corrosive environments.

Can galvanized grating be used in food processing environments?

Yes, many galvanized grating options are suitable for food processing areas. Galvanized serrated grating, for example, is often used due to its slip - resistant surface and ease of cleaning. However, it’s important to ensure the galvanized coating meets food safety standards, as some applications may require additional certifications or coatings to prevent contamination.

What is the load capacity of galvanized steel grating?

The load capacity of grating galvanized steel varies depending on the design, bar spacing, and thickness of the steel. Standard bar grating can support light to heavy loads, ranging from pedestrian traffic to heavy machinery. Manufacturers typically provide load tables that detail the maximum weight each grating type can safely bear, allowing users to select the appropriate product for their specific needs.

How do I maintain galvanized grating?

Maintenance for galvanized grating is minimal. Regularly clean the surface with a mild detergent and water to remove dirt, grease, or debris that could trap moisture and cause corrosion. Inspect the grating periodically for signs of damage, such as loose bars or chips in the galvanized coating. For minor damage, touch up the affected area with a zinc - rich paint to prevent rust from spreading.

Is hot dip galvanized grating more expensive than other types?

Grating hot dip galvanized may have a higher upfront cost due to the specialized coating process, but it offers superior durability and a longer service life compared to other galvanized methods. In environments where corrosion is a major concern, the long - term cost savings from reduced maintenance and replacement make hot dip galvanized grating a cost - effective choice.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingFréttirNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedFréttirNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedFréttirNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMFréttirNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipFréttirNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipFréttirNov.10,2025