- Iðnaðarsvæði, suður af Anping Town, Hengshui, Hebei, Kína.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Enska

Enska  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Enska

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

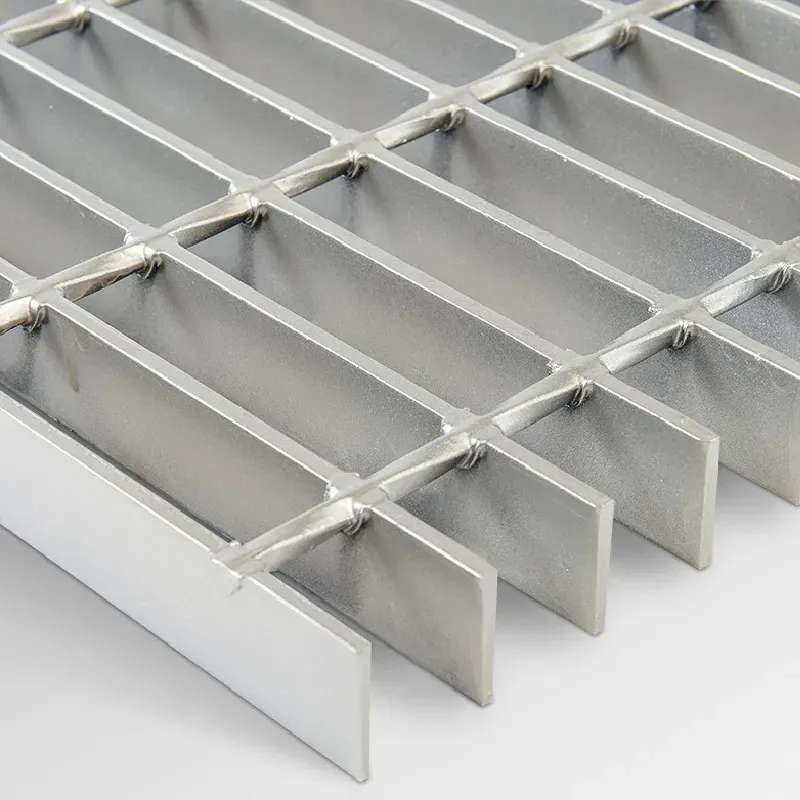

Discover The Durability And Versatility Of Galvanised Grating Solutions

In the realm of robust and reliable flooring and infrastructure, galvanised products stand out for their exceptional resistance to corrosion and enduring strength. Among the key options shaping modern industrial, commercial, and residential projects are galvanised floor grating, galvanised grating, galvanised grid, galvanised iron grating, and galvanised metal grating. These solutions blend practicality with long - lasting performance, making them indispensable in environments where durability and safety are paramount.

The Unmatched Corrosion Resistance of Galvanised Grating

Galvanised grating is a cornerstone of outdoor and high - moisture applications, thanks to its zinc coating that forms a protective barrier against rust and degradation. In coastal areas or industrial zones with high humidity, this coating acts as a shield, preventing the underlying metal from succumbing to corrosive elements. For example, in outdoor walkways or bridge decks exposed to constant rain and salt air, galvanised grating maintains its structural integrity over decades, reducing the need for frequent replacements. The galvanisation process ensures that even if the surface is scratched, the zinc layer continues to protect the metal through a process called sacrificial corrosion.

Galvanised Floor Grating: Strength Meets Functionality

Galvanised floor grating is engineered to handle heavy loads while offering practical benefits like drainage and ventilation. In industrial settings such as factories and warehouses, these gratings support the movement of forklifts and heavy machinery while allowing liquids and debris to pass through, minimizing slip hazards and simplifying cleaning. The open grid design of galvanised floor grating also enhances airflow, making it suitable for areas where ventilation is crucial, such as wastewater treatment plants or parking garages. The combination of strength and functionality makes it a go - to choice for environments that demand both performance and safety.

Exploring the Versatility of Galvanised Grid Systems

Galvanised grid solutions offer flexibility in design and application, catering to a wide range of projects. In commercial buildings, galvanised grids can be used to create mezzanine floors or raised platforms, providing sturdy support for storage or work areas. Their modular nature allows for easy installation and customization, making them ideal for retrofitting existing structures. For residential use, galvanised grid can be incorporated into decking or patio flooring, offering a slip - resistant surface that withstands outdoor elements while adding a modern aesthetic. The grid pattern can be adapted to different spacing requirements, balancing load - bearing capacity with visual appeal.

The Robustness of Galvanised Iron Grating

Galvanised iron grating combines the inherent strength of iron with the protective benefits of galvanisation. This makes it suitable for heavy - duty applications where durability is non - negotiable, such as railway platforms, industrial staircases, or mining sites. The iron core provides exceptional load - bearing capacity, while the zinc coating ensures resistance to abrasion and corrosion. In mining operations, where equipment and foot traffic are constant and harsh conditions prevail, galvanised iron grating offers a reliable flooring solution that can withstand the rigors of daily use without compromising safety.

Galvanised Metal Grating: A Blend of Materials and Performance

Galvanised metal grating encompasses a range of materials, including steel and iron, all unified by the galvanisation process. This versatility allows for tailored solutions based on specific project needs. For example, in food processing facilities, galvanised steel grating is preferred for its hygienic properties and ease of cleaning, while in automotive workshops, galvanised iron grating may be chosen for its ability to withstand oil spills and heavy vehicle traffic. Galvanised metal grating also finds use in architectural applications, such as decorative railings or facade elements, where its durability is paired with a sleek, industrial look.

FAQ: Key Insights into Galvanised Grating Solutions

How does galvanisation enhance the lifespan of grating?

Galvanisation involves coating the metal with a layer of zinc, which creates a physical barrier against moisture, salt, and chemicals. Additionally, if the coating is damaged, the zinc acts as a sacrificial anode, corroding instead of the base metal. This dual protection extends the lifespan of galvanised grating significantly, making it a cost - effective choice compared to uncoated alternatives.

Can galvanised floor grating be used in residential settings?

Yes, galvanised floor grating is suitable for residential use, particularly in outdoor areas like balconies, decks, or basements prone to water accumulation. Its slip - resistant surface and drainage capabilities make it a safe option for homes, while the galvanised finish adds a modern touch that complements various architectural styles.

What factors should I consider when selecting a galvanised grid?

Key factors include the intended load (foot traffic, vehicles, or machinery), environmental conditions (indoor vs. outdoor, humidity levels), and design preferences (grid spacing, finish). For high - corrosion environments, prioritize thicker galvanised coatings. For aesthetic purposes, explore options like powder - coated finishes over the galvanised layer to add color while maintaining protection.

Is maintenance required for galvanised iron grating?

Maintenance is minimal for galvanised iron grating. Regularly sweep or hose off debris to prevent buildup, and inspect for any signs of damage to the galvanised layer. In most cases, no additional treatments are needed, as the zinc coating provides long - lasting protection. If scratches or cuts expose the base metal, touching up with a zinc - rich paint can help maintain corrosion resistance.

Can galvanised metal grating be customized for unique projects?

Yes, manufacturers often offer customization for galvanised metal grating, including custom sizes, grid patterns, and finishes. This allows for precise fitting in irregular spaces or tailored load - bearing capabilities. Whether for a specialized industrial application or a unique architectural design, galvanised metal grating can be adapted to meet specific project requirements.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingFréttirNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedFréttirNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedFréttirNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMFréttirNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipFréttirNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipFréttirNov.10,2025