- Iðnaðarsvæði, suður af Anping Town, Hengshui, Hebei, Kína.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Enska

Enska  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Enska

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Decoding Costs and Choices in Steel Grating Solutions

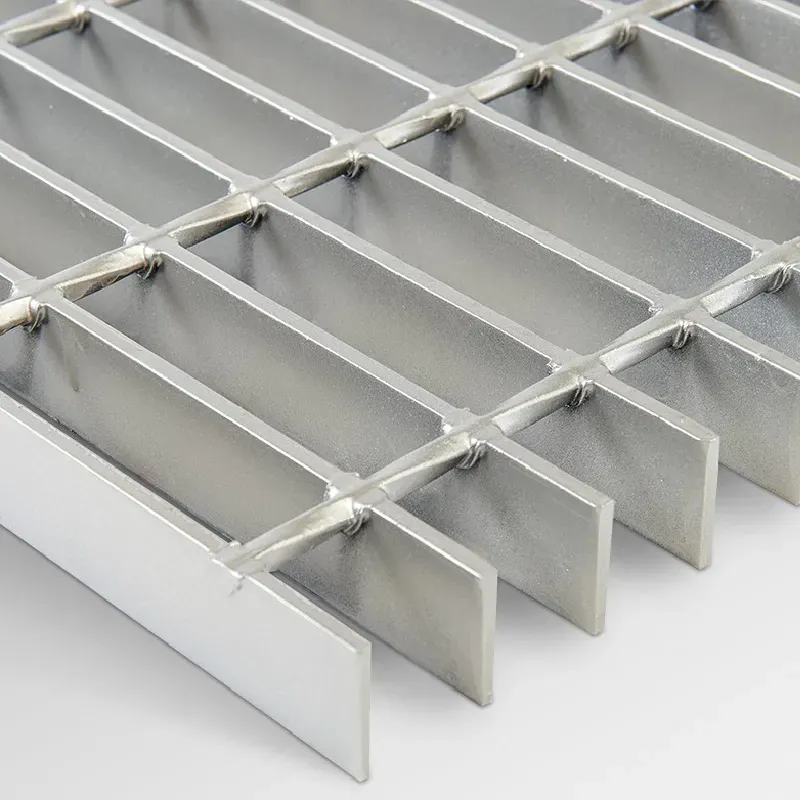

In the realm of industrial and architectural materials, steel grating stands out for its durability and versatility. When evaluating options, understanding pricing dynamics is key. The keywords grating steel price, galvanized steel grating prices, floor grating price, galvanised grating price, and metal grating price all relate to the financial aspects of these products, influenced by material, finish, and application. This overview explores how these factors shape costs and guide informed decisions.

Unraveling Grating Steel Price Drivers

The grating steel price is fundamentally tied to raw material costs and manufacturing complexity. Steel grades, such as carbon or stainless steel, impact pricing—stainless steel being costlier due to corrosion resistance. For example, a standard carbon steel grating for a factory floor may start at a lower base price, while marine environments might require pricier stainless steel to withstand salt exposure. Additionally, the density of the grating’s grid pattern affects material usage: tighter spacing or heavier gauge steel increases costs but enhances load - bearing capacity. Suppliers often provide quotes based on project size, with bulk orders potentially reducing the grating steel price per unit.

The Impact of Galvanized Finishes on Pricing

Galvanized steel grating prices reflect the added value of corrosion protection. Hot - dip galvanization, a popular finish, involves coating steel with zinc to extend lifespan in harsh environments. This process adds to production costs, making galvanized options more expensive than uncoated steel gratings. For instance, a galvanized steel grating for an outdoor walkway may cost 10–20% more than a plain steel counterpart but offers decades of rust resistance. The thickness of the zinc coating (measured in microns) also influences pricing, with heavier coatings providing superior protection at a higher cost.

Factors Influencing Floor Grating Price

Floor grating price varies widely based on intended use and design. In industrial settings, heavy - duty floor gratings for machinery or vehicle traffic require robust materials and thicker bars, driving up costs. Conversely, lightweight gratings for commercial spaces like stair treads or balcony floors may use thinner steel and wider spacing, reducing expenses. Surface finishes also play a role: serrated or embossed textures for slip resistance add to the floor grating price but enhance safety in wet or oily environments. Customizations, such as curved shapes or cutouts for pipes, further impact costs due to increased fabrication time.

Galvanised Grating Price: Regional and Market Trends

Galvanised grating price (using the UK spelling) can be influenced by regional supply chains and market demand. In areas with high humidity or industrial pollution, the demand for galvanized gratings is higher, potentially affecting pricing. Seasonal fluctuations in steel production—such as reduced output during maintenance periods—can also drive short - term price increases. Suppliers may offer tiered pricing based on order volume, with larger projects in sectors like construction or infrastructure development securing more competitive galvanised grating price quotes. Comparing quotes from multiple vendors is essential to navigate these variables and find optimal value.

Metal Grating Price: A Broader Perspective

The term metal grating price encompasses a range of materials beyond steel, such as aluminum or copper, each with distinct cost profiles. Aluminum gratings, while lighter and corrosion - resistant, often come at a higher initial cost than steel but offer long - term savings in maintenance. Copper gratings, used for decorative or specialized applications, are premium due to material rarity. For most industrial needs, steel remains the cost - effective choice, with metal grating price for steel typically lower than non - ferrous alternatives. However, the total cost of ownership—including maintenance and replacement—must be weighed against upfront expenses.

FAQ: Navigating Steel Grating Costs

How do I compare quotes for galvanized steel grating prices?

When comparing quotes, verify the following:

- Material grade: Ensure all suppliers reference the same steel type (e.g., ASTM A36).

- Galvanization standard: Check for compliance with ISO 1461 or ASTM A123 for hot - dip galvanizing.

- Dimensions: Confirm bar size, spacing, and overall dimensions to avoid apples - to - oranges comparisons.

- Additional costs: Ask about delivery fees, installation, or custom cuts that might affect the final price.

Can I reduce floor grating price without compromising quality?

Yes. Consider these strategies:

- Standard designs: Opt for pre - fabricated grating instead of custom shapes.

- Bulk orders: Larger quantities often qualify for volume discounts.

- Alternative finishes: If corrosion risk is low, consider powder coating instead of galvanization to save costs.

- Recycled steel: Some suppliers offer gratings made from recycled materials at a lower price point.

Why do galvanised grating price quotes vary between suppliers?

Price variations can stem from:

- Raw material sources: Suppliers using imported steel may face fluctuating costs due to tariffs or logistics.

- Fabrication methods: Automated production lines may offer lower costs than manual fabrication.

- Geographic location: Suppliers in areas with higher labor or energy costs may price products accordingly.

- Service inclusions: Some vendors bundle installation or maintenance into the price, while others offer it as an add - on.

How does the lifespan of galvanized steel affect its overall cost?

While galvanized steel grating prices are higher upfront, their lifespan (25–50 years in most environments) often makes them cheaper long - term. Uncoated steel may corrode within 5–10 years in harsh conditions, requiring replacement. Galvanization reduces maintenance costs by minimizing rust and extends the grating’s useful life, providing better value over time.

Are there hidden costs in metal grating price quotes?

Common hidden costs include:

- Custom modifications: Unquoted fees for cutting, drilling, or shaping gratings to fit specific spaces.

- Accessories: Costs for clips, bolts, or edge trims needed for installation.

- Expedited shipping: Rush orders may incur higher delivery fees.

- Testing fees: Some projects require load - testing certifications, which can add to the total cost. Always request a detailed breakdown to avoid surprises.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingFréttirNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedFréttirNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedFréttirNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMFréttirNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipFréttirNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipFréttirNov.10,2025