- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 17, 2025 13:18

Back to list

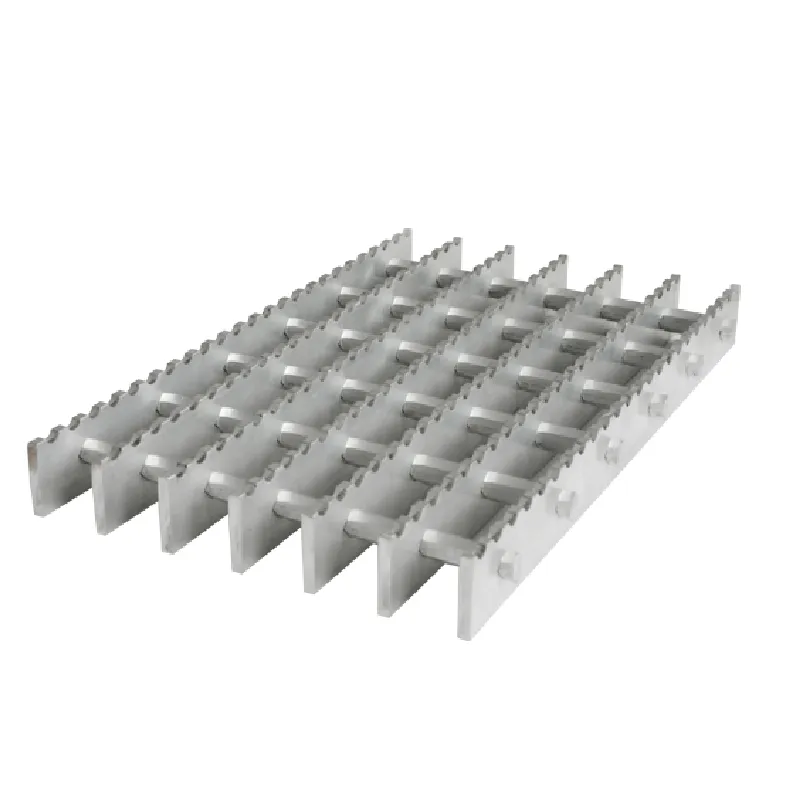

Riveted Grating

Grating steel floors have revolutionized industrial design with their remarkable durability and versatility. Their unique construction provides a clear advantage in various settings, from manufacturing facilities to architectural designs. This article delves into the many reasons why grating steel floors stand out as a formidable choice for demanding environments, showcasing the firsthand experiences, expert evaluations, authoritative insights, and trusted recommendations that solidify their place in the modern workspace.

Efficiency in installation and maintenance cannot be understated for enterprises looking to optimize both time and cost. Grating steel floors are lauded for their straightforward installation process. Prefabricated modules are often used, which streamline installation and reduce downtime for businesses. Maintenance, another crucial consideration in long-term cost assessments, is equally straightforward. Routine inspection and minimal cleaning are generally sufficient to maintain optimal functionality. Companies repeatedly highlight these aspects in testimonials, reflecting a trust-based relationship with grating steel flooring solutions that enhance operational effectiveness. Moreover, the green credential of grating steel floors is a topic of growing significance as industries strive for sustainability. Steel is one of the most recycled materials on the planet, and the recyclability of grating steel floors underscores their environmental benefits. This characteristic meets stringent industry regulations and consumer expectations for sustainable practices, offering businesses an authoritative shield against environmental criticisms. Experts in environmental design and sustainability recognize the vital role that these floors play in reducing a facility's carbon footprint, reinforcing their use as a responsible material choice. In integration within industrial technology, grating steel floors accommodate a variety of utility needs such as ventilation and drainage. Their open grid design ensures optimal airflow and water passage, which is essential in many settings. Factory floors with heavy machinery can often overheated, but the ventilation provided by grating steel helps maintain necessary operational temperatures. Similarly, environments with high moisture levels or spill-prone industries benefit from this drainage capability – a feature consistently backed by industrial engineers and safety experts who trust in the structural and functional integrity of steel grating solutions. In conclusion, grating steel floors exemplify a product category where real-world experience, expert engineering, authoritative understanding, and trusted utility converge. Their robust structure, adaptive nature, design flexibility, and maintenance ease make them a cornerstone of industrial innovation. The cross-industry acclaim they receive is borne out of consistent performance and enduring quality, which continue to redefine standards in both industrial efficiency and environmental responsibility. As businesses look to future-proof their operations, grating steel floors provide a well-rounded, authoritative choice supported by years of industry success stories and expert endorsements.

Efficiency in installation and maintenance cannot be understated for enterprises looking to optimize both time and cost. Grating steel floors are lauded for their straightforward installation process. Prefabricated modules are often used, which streamline installation and reduce downtime for businesses. Maintenance, another crucial consideration in long-term cost assessments, is equally straightforward. Routine inspection and minimal cleaning are generally sufficient to maintain optimal functionality. Companies repeatedly highlight these aspects in testimonials, reflecting a trust-based relationship with grating steel flooring solutions that enhance operational effectiveness. Moreover, the green credential of grating steel floors is a topic of growing significance as industries strive for sustainability. Steel is one of the most recycled materials on the planet, and the recyclability of grating steel floors underscores their environmental benefits. This characteristic meets stringent industry regulations and consumer expectations for sustainable practices, offering businesses an authoritative shield against environmental criticisms. Experts in environmental design and sustainability recognize the vital role that these floors play in reducing a facility's carbon footprint, reinforcing their use as a responsible material choice. In integration within industrial technology, grating steel floors accommodate a variety of utility needs such as ventilation and drainage. Their open grid design ensures optimal airflow and water passage, which is essential in many settings. Factory floors with heavy machinery can often overheated, but the ventilation provided by grating steel helps maintain necessary operational temperatures. Similarly, environments with high moisture levels or spill-prone industries benefit from this drainage capability – a feature consistently backed by industrial engineers and safety experts who trust in the structural and functional integrity of steel grating solutions. In conclusion, grating steel floors exemplify a product category where real-world experience, expert engineering, authoritative understanding, and trusted utility converge. Their robust structure, adaptive nature, design flexibility, and maintenance ease make them a cornerstone of industrial innovation. The cross-industry acclaim they receive is borne out of consistent performance and enduring quality, which continue to redefine standards in both industrial efficiency and environmental responsibility. As businesses look to future-proof their operations, grating steel floors provide a well-rounded, authoritative choice supported by years of industry success stories and expert endorsements.

Share

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025