- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 11, 2025 05:17

Back to list

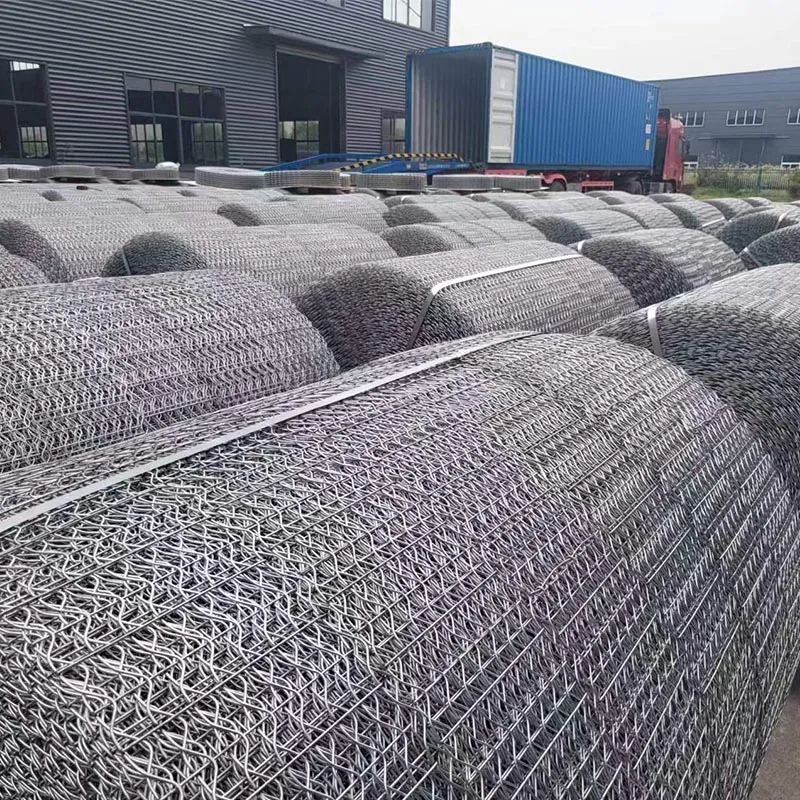

metal grating for sale

Galvanised metal grating, a cornerstone in numerous industries, offers a perfect blend of durability, efficiency, and safety. Understanding its roles and benefits requires an insight into its material composition, application spectrum, and the technology behind its manufacturing.

Moreover, galvanised metal grating is instrumental in ensuring compliance with safety regulations. Companies within heavy industries, like mining and construction, face stringent safety standards. Utilizing galvanised grating in these sectors helps meet safety audits due to its excellent load distribution and resistance to slipping, thus minimizing workplace accidents and enhancing operational efficiency. Investing in galvanised metal grating also speaks to trustworthiness—a commitment to providing environments that protect employees and the public alike. By choosing high-quality grating solutions, businesses demonstrate responsibility and foresight in anticipating potential hazards and addressing them proactively. From an architectural standpoint, galvanised metal grating provides aesthetic value without compromising functionality. This dual-purpose aspect appeals to architects and designers who strive for both beauty and practicality in industrial and commercial spaces. The grating's ability to complement industrial aesthetics while delivering robust performance opens new avenues in building design and functionality. As the demand for resilient infrastructures rises, galvanised metal grating will continue to play an essential role in ensuring structures meet high standards of performance and safety. Expertise in its deployment and correct application will further underscore its value, making it an indispensable component in modern construction and industry. To sum up, galvanised metal grating stands as a testament to engineered ingenuity with its protective galvanised coating. When choosing the right materials for projects requiring a balance of durability, safety, and environmental consciousness, it offers unmistakable benefits backed by professional expertise and real-world experience. As more industries recognize its value, galvanised metal grating will undoubtedly remain a key player in building sustainable, resilient infrastructures worldwide.

Moreover, galvanised metal grating is instrumental in ensuring compliance with safety regulations. Companies within heavy industries, like mining and construction, face stringent safety standards. Utilizing galvanised grating in these sectors helps meet safety audits due to its excellent load distribution and resistance to slipping, thus minimizing workplace accidents and enhancing operational efficiency. Investing in galvanised metal grating also speaks to trustworthiness—a commitment to providing environments that protect employees and the public alike. By choosing high-quality grating solutions, businesses demonstrate responsibility and foresight in anticipating potential hazards and addressing them proactively. From an architectural standpoint, galvanised metal grating provides aesthetic value without compromising functionality. This dual-purpose aspect appeals to architects and designers who strive for both beauty and practicality in industrial and commercial spaces. The grating's ability to complement industrial aesthetics while delivering robust performance opens new avenues in building design and functionality. As the demand for resilient infrastructures rises, galvanised metal grating will continue to play an essential role in ensuring structures meet high standards of performance and safety. Expertise in its deployment and correct application will further underscore its value, making it an indispensable component in modern construction and industry. To sum up, galvanised metal grating stands as a testament to engineered ingenuity with its protective galvanised coating. When choosing the right materials for projects requiring a balance of durability, safety, and environmental consciousness, it offers unmistakable benefits backed by professional expertise and real-world experience. As more industries recognize its value, galvanised metal grating will undoubtedly remain a key player in building sustainable, resilient infrastructures worldwide.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025