- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

فېۋرال . 05, 2025 05:08

Back to list

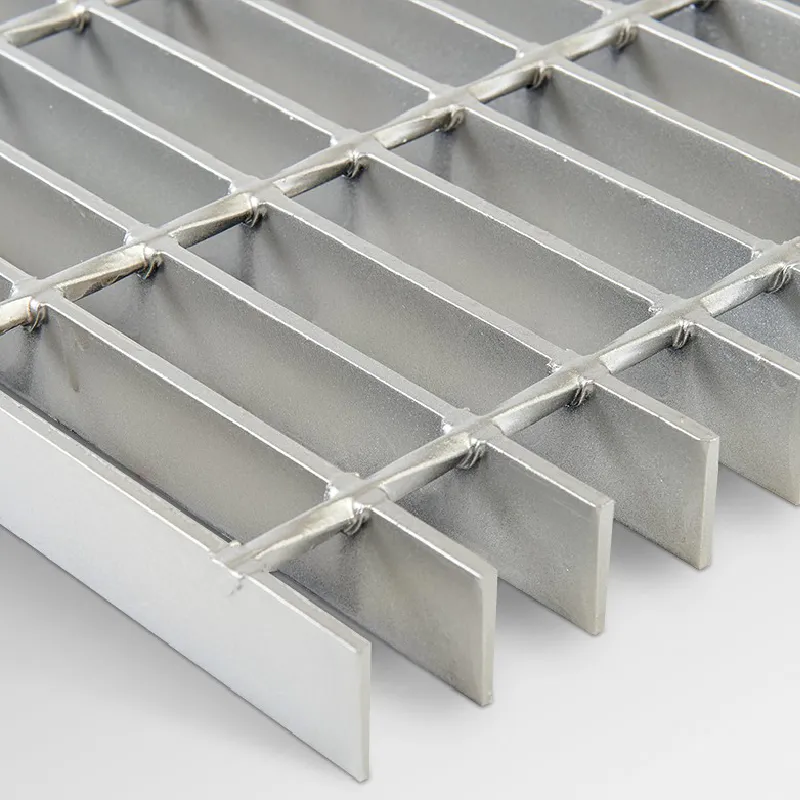

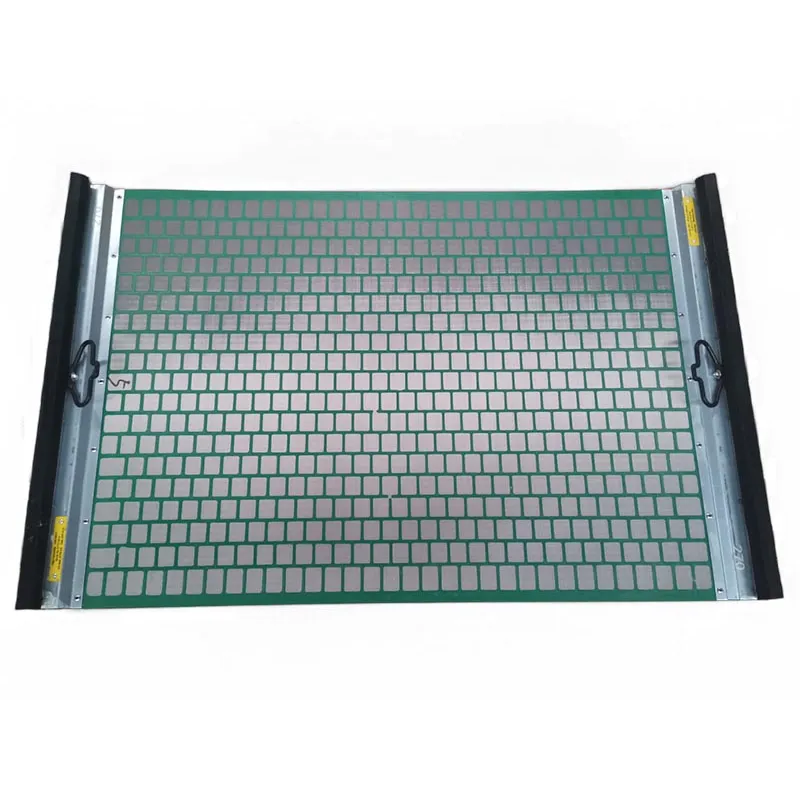

Press-Locked Steel Grating

In the world of industrial applications, heavy-duty mild steel grating stands out as a versatile solution known for its strength and durability. Understanding the benefits and practical applications of this material lends itself to industry experts and construction professionals who seek optimal solutions to complex structural challenges.

Trustworthiness is paramount in construction projects, where safety and performance are non-negotiable. Testimonials from industry veterans reinforce mild steel grating’s position as a trustable commodity. Its resistance to hazardous environments, such as those involving extreme temperatures and corrosive substances, ensures it stands the test of time. This durability is not only a testament to the material’s superior engineering but also serves as a critical trust point for project managers overseeing high-risk installations. In practice, heavy-duty mild steel grating is beneficial for more than just its physical attributes. Its economic efficiency—stemming from its low initial cost and minimal maintenance requirements—makes it a favorable choice for budget-conscious projects without compromising on quality. The galvanization process often used increases its resistance to rust and environmental damage, further extending its lifespan, which is a boon for cost management. Practical applications of this material reveal its broader impact on industry projects. Engineers have found success using heavy-duty mild steel grating across several high-profile projects—from constructing offshore drilling rigs to developing large-scale infrastructure like bridges and public transit systems. Its non-slip surface is another characteristic that improves safety for workers, which is particularly beneficial in environments with strict safety protocols. In conclusion, heavy-duty mild steel grating represents a confluence of strength, flexibility, reliability, and economy—qualities essential to modern industrial applications. It stands as a cornerstone material in various sectors, supporting the construction of environments that prioritize safety, durability, and performance. From seasoned engineers to first-time users, the choice of this grating material carries an assurance of quality that is backed by expert validation and industry-wide acknowledgment. As a strategic investment, it not only meets but often exceeds the rigorous demands placed upon it, making it a staple in the lexicon of construction materials.

Trustworthiness is paramount in construction projects, where safety and performance are non-negotiable. Testimonials from industry veterans reinforce mild steel grating’s position as a trustable commodity. Its resistance to hazardous environments, such as those involving extreme temperatures and corrosive substances, ensures it stands the test of time. This durability is not only a testament to the material’s superior engineering but also serves as a critical trust point for project managers overseeing high-risk installations. In practice, heavy-duty mild steel grating is beneficial for more than just its physical attributes. Its economic efficiency—stemming from its low initial cost and minimal maintenance requirements—makes it a favorable choice for budget-conscious projects without compromising on quality. The galvanization process often used increases its resistance to rust and environmental damage, further extending its lifespan, which is a boon for cost management. Practical applications of this material reveal its broader impact on industry projects. Engineers have found success using heavy-duty mild steel grating across several high-profile projects—from constructing offshore drilling rigs to developing large-scale infrastructure like bridges and public transit systems. Its non-slip surface is another characteristic that improves safety for workers, which is particularly beneficial in environments with strict safety protocols. In conclusion, heavy-duty mild steel grating represents a confluence of strength, flexibility, reliability, and economy—qualities essential to modern industrial applications. It stands as a cornerstone material in various sectors, supporting the construction of environments that prioritize safety, durability, and performance. From seasoned engineers to first-time users, the choice of this grating material carries an assurance of quality that is backed by expert validation and industry-wide acknowledgment. As a strategic investment, it not only meets but often exceeds the rigorous demands placed upon it, making it a staple in the lexicon of construction materials.

Share

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025