- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

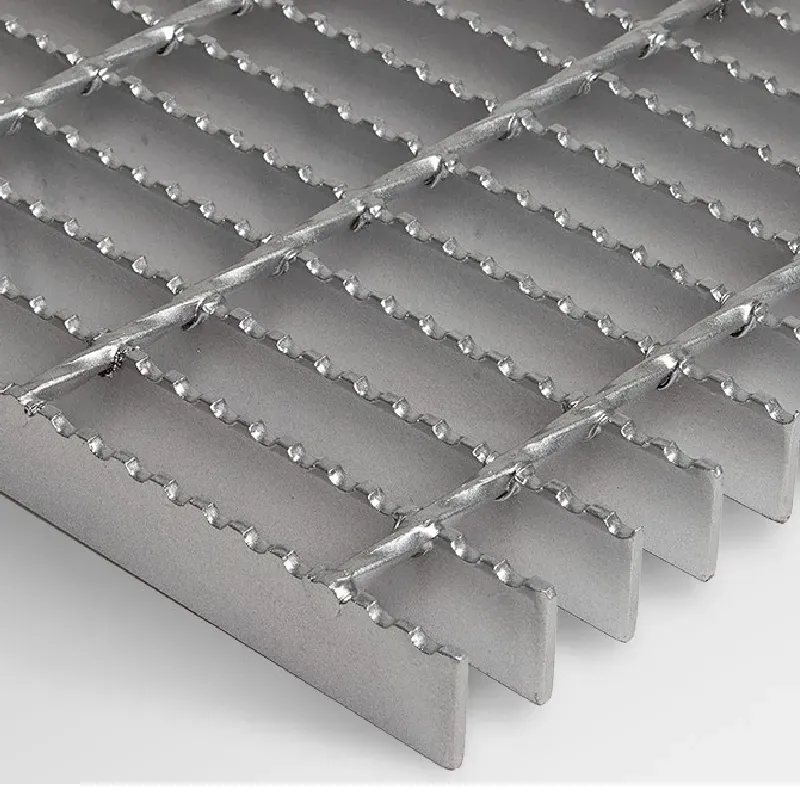

High-Quality Steel Floor Grates for Sale – Durable Metal & Stainless Steel Options

- Introduction to steel floor grates for sale

and their importance - Technical advantages of different materials

- Comparative analysis of flooring grate manufacturers

- Customization options for steel floor grates

- Real-world applications and case studies

- Choosing the right grate: A detailed buyer’s guide

- Conclusion: Why you should consider steel floor grates for sale

(steel floor grates for sale)

Introduction: The Rising Demand for Steel Floor Grates for Sale

In today’s rapidly expanding construction and infrastructure industry, the demand for high-performance steel floor grates for sale is accelerating. These grates are the backbone in numerous sectors such as industrial, commercial, residential, and municipal projects where drainage, load support and safety are paramount. Robust grating systems crafted from steel, stainless steel, and other metals provide unmatched strength and durability compared to traditional flooring solutions. Industry data shows that global steel floor grating sales have risen by 8.2% CAGR over the past five years, driven by investments in urban development and modern manufacturing plants. As safety regulations become more strict, the necessity for reliable and compliant grating systems intensifies, making the process of choosing the right floor grate more crucial than ever.

Material Analysis: Technical Advantages of Steel, Stainless Steel, and Metal Grates

Not all floor grates are created equal. The selection of grate material has a direct impact on load capacity, resistance to corrosion, lifespan, and maintenance requirements. Steel floor grates are renowned for their high tensile strength, supporting loads of up to 7 tons per square meter, making them ideal for heavy-duty industrial uses.

- Carbon Steel Grates: Widely used due to their superior load-bearing capabilities and cost efficiency. However, they require periodic maintenance to prevent rust, especially in outdoor or wet environments.

- Stainless Steel Grates: Exceptionally resistant to chemical corrosion and rust, which makes them suitable for facilities like food processing plants, chemical factories, and areas exposed to the elements. While the initial cost is 15-25% higher than carbon steel, their maintenance costs are considerably lower.

- Other Metal Grates: Aluminum and galvanized options provide lighter-weight solutions with moderate strength, often used in public infrastructure for ease of installation and minimal maintenance.

State-of-the-art manufacturing often incorporates slip-resistant coatings, anti-rust treatments, and precision welding techniques, boosting the grates’ safety and durability for decades of reliable service.

Manufacturer Comparison: Performance, Quality, and Value

Choosing the ideal steel or metal floor grate is not merely about the material; it’s also about the manufacturer’s expertise, technological innovation, pricing transparency, and after-sales support. Here’s a comparative data table of four leading manufacturers, based on criteria such as load rating, surface treatment, customizability, and warranty terms.

| Manufacturer | Material Options | Maximum Load (tons/m²) | Corrosion Resistance | Lead Time (days) | Warranty (years) | Customization |

|---|---|---|---|---|---|---|

| SteelGridPro | Carbon, Stainless Steel | 7.2 | High (with coatings) | 14-21 | 10 | Comprehensive |

| Metalaire Solutions | Galvanized, Stainless Steel | 6.8 | Advanced galvanizing | 10-15 | 8 | Standard & Custom |

| UrbanGrid Systems | Aluminum, Carbon Steel | 4.5 | Moderate | 20-30 | 5 | Limited |

| InoxFloor Grates | Stainless Steel Only | 7.5 | Exceptional | 12-18 | 12 | Full Customization |

As depicted, InoxFloor Grates excel in both corrosion resistance and warranty, while SteelGridPro leads in maximum load and comprehensive customization. Prospective buyers are encouraged to assess not just the listed specs but also each company's quality assurance processes and client references.

Customization: Designing Floor Grates to Match Any Application

With the diversity of project requirements, from high-trafficked urban pathways to sterile laboratory environments, off-the-shelf grates may not suffice. Leading suppliers offer a spectrum of customizable options:

- Dimensions & Shape: Custom-cut sizes, shapes (e.g., square, round, trapezoid), and profiles meet unique architectural or engineering demands.

- Surface Finish: Anti-slip patterns, smooth-polished, electrostatic powder-coated, or acid-washed surfaces tailored for safety and aesthetics.

- Bearing Bar Spacing: Adjusted for the needed load rating, pedestrian comfort, debris filtration, or ADA compliance.

- Load & Support Requirements: Engineered to withstand forklift traffic, high moisture, humidity, or temperature extremes.

- Locking & Framing Accessories: Integration with fastener kits, security locks, or modular edge frames for rapid installation and theft prevention.

Advanced manufacturers employ 3D modeling and simulation to validate custom designs, ensuring optimal performance before fabrication. Whether for retrofitting a historical site or building cutting-edge industrial plants, bespoke steel floor grates ensure every box is checked.

Application Scenarios: Proven Case Studies Across Industries

Practical application of metal and stainless steel grates extends beyond simple drainage. Consider these real-world scenarios:

- Automotive Assembly Plants: Durable carbon steel grates withstand multi-ton vehicle loads while facilitating seamless spill drainage on production lines, driving a 30% reduction in workplace accidents from slips.

- Food Processing Facilities: Stainless steel floor grates with fine mesh structures are installed, ensuring sanitary conditions and preventing material contamination. These grates have doubled the cleaning efficiency compared to traditional concrete channels.

- Public Transit Hubs: Metal floor gratings in stations and platforms manage heavy pedestrian flows, featuring anti-slip finishes to meet rigorous safety standards. Retrofits using high-quality grates reported a 40% decrease in maintenance incidents within two years.

- Urban Drainage Infrastructure: Municipalities investing in galvanized metal floor grates have extended lifespans by up to 50% versus older cast-iron models, requiring fewer replacements and lowering lifecycle costs.

- Architectural Design: Customized stainless steel solutions have enabled eye-catching additions to luxury commercial complexes, balancing function and aesthetics for entrances, atriums, and rooftop gardens.

The adaptability of steel grates supports endless custom applications, with new innovations continuously emerging from collaborative projects between architects, engineers, and manufacturers.

Buyer’s Guide: Critical Factors to Consider

Selecting the right metal floor grates for sale can drastically affect operational efficiency, employee safety, longevity, and overall project costs. Key criteria include:

- Load Requirements: Analyze the expected static and dynamic loads to ensure the grate’s structural integrity and compliance with industry standards.

- Environmental Exposure: Assess potential for exposure to chemicals, moisture, or temperature extremes, guiding the choice between carbon steel, galvanized, and stainless steel grates.

- Installation & Maintenance: Look for products with modular designs and easy-to-replace panels, minimizing downtime during maintenance or future upgrades.

- Certifications & Compliance: Check for compliance with regulations such as CE, ASTM, or ISO standards, as well as meeting ADA requirements for public safety.

- Supplier Reliability: Prioritize vendors with proven track records, robust warranties, responsive technical support, and transparent lead times.

The choice should ultimately align technical specifications with practical realities on the ground, ensuring maximum return on investment and peace of mind.

Conclusion: The Strategic Value of Steel Floor Grates for Sale

As urban landscapes modernize and industry standards evolve, incorporating steel floor grates for sale into construction and renovation projects stands out as a future-proof decision. Not only do they deliver proven durability, safety, and adaptability across applications, but they also enhance cost-effectiveness through long operational life and reduced maintenance interventions. From heavy-load manufacturing plants to stylish architectural installations, steel, stainless steel, and other metal floor grates present versatile solutions that keep pace with stringent demands. Buyers who approach their selection process with critical insight—considering technical data, manufacturer credibility, customization, and practical applications—position themselves for lasting project success.

(steel floor grates for sale)

FAQS on steel floor grates for sale

Q: What materials are available for steel floor grates for sale?

A: We offer steel floor grates in various materials including standard steel, stainless steel, and other metals. These options ensure durability and corrosion resistance. Contact us for more details on available materials.Q: Are there different sizes of metal floor grates for sale?

A: Yes, metal floor grates for sale come in a range of sizes and load capacities. Custom sizes are also available to fit your specific requirements. Please browse our catalog or inquire for custom orders.Q: What are the advantages of stainless steel grates for sale?

A: Stainless steel grates provide superior resistance to corrosion, making them ideal for demanding environments. They are easy to clean and maintain. This makes them perfect for commercial and industrial uses.Q: Can I order steel floor grates for outdoor use?

A: Absolutely, our steel floor grates for sale are suitable for both indoor and outdoor applications. Choose galvanized or stainless options for enhanced weather resistance. Contact our team to discuss your outdoor project needs.Q: Do metal floor grates for sale require special installation?

A: Installation is straightforward and typically requires common tools. However, we can provide instructions or recommend professional assistance for larger projects. Let us know if you need installation guidance.-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025