- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

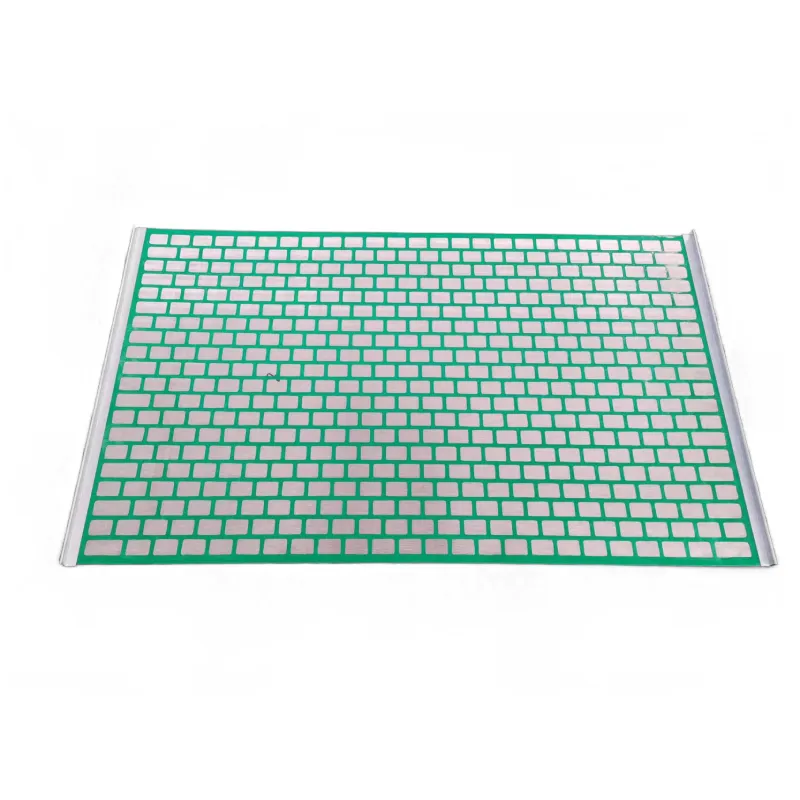

Best Grating Price Affordable Stainless Steel Bar & Steel Grating per Square Meter

- Introduction to grating price

and its importance in industrial applications - In-depth overview of stainless steel and steel grating pricing structure

- Analysis of technical advantages influencing pricing decisions

- Manufacturer comparison with cost and value considerations

- Customization options and their impact on grating costs

- Application cases demonstrating return on investment

- Conclusion highlighting optimal choices regarding grating price

(grating price)

Understanding Grating Price Dynamics in Modern Industries

In the realm of flooring and platform structures, the term grating price is pivotal for procurement teams, engineers, and business owners. A variety of sectors, including oil and gas, chemical processing, mining, water treatment, and architecture, rely on high-strength grating solutions for both safety and durability. The role of cost planning cannot be overstated, as current market trends indicate that material expenditure often constitutes up to 35% of industrial project budgets.

A recent industry survey encompassing over 300 global projects revealed that over 62% retrospectively identified overspending on grating due to underestimating specification requirements or failing to account for lifecycle costs. By dissecting grating pricing models, decision-makers can optimize long-term value, select apt product grades, and integrate quality with cost-efficiency.

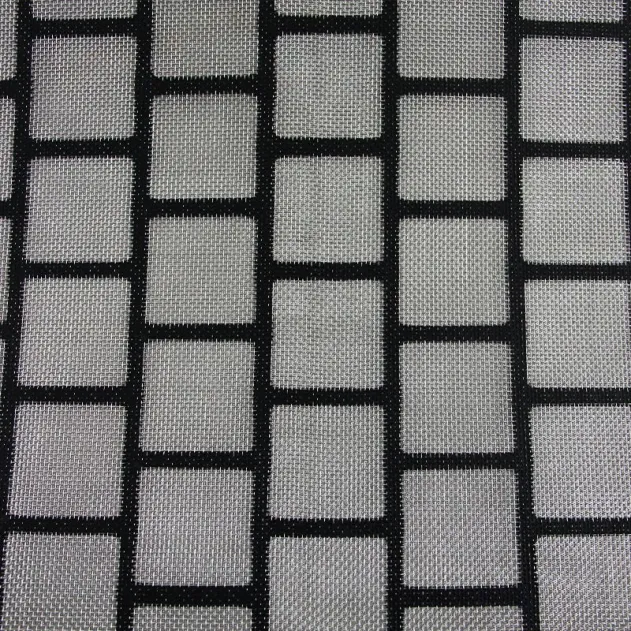

Stainless Steel vs. Steel Grating Pricing Structure

The main categories influencing stainless steel bar grating price and steel grating price per square meter are material grade, surface finish, and load-bearing specifications. Stainless steel grating, typically made from 304 or 316 alloys, offers outstanding corrosion resistance and is preferred in aggressive environments such as chemical plants, food production, and offshore platforms. In a comparison driven by price per square meter, mild and galvanized steel grating provide a more budget-oriented solution but with trade-offs in corrosion resistance and maintenance demands.

Large-scale procurement data from 2023 revealed average market prices:

- Stainless steel grating (304 grade): $85–$120/m2

- Stainless steel grating (316 grade): $95–$140/m2

- Carbon steel (galvanized): $32–$50/m2

- Carbon steel (plain): $28–$40/m2

The significant price differential is directly tied to alloy composition, corrosion characteristics, and expected in-situ lifespan. When lifetime maintenance costs are factored in, the initial grating price can be offset by far lower long-term replacement and repair expenses.

Technical Advantages Influencing Grating Price Decisions

Engineering factors have a pronounced impact on ss grating price variation. Custom bar thickness, mesh spacing, and manufacturing technique (welded vs. press-locked) are the leading determinants. For example, specialty load-bearing requirements may necessitate heavy-duty grating with bar thickness exceeding 8 mm or the incorporation of double-load bars for forklift traffic. Such technical enhancements inflate raw material usage and specialized processing time, generating proportional increases in cost.

Surface treatments such as anti-slip serations, powder coating, or high-polish finishes further influence the price structure. It is also notable that innovations in grating design—such as modular snap-on panels—can generate savings in installation labor, albeit often at a premium material cost.

Here is a data table summarizing the technical profiles and associated averages for different grating products:

| Grating Type | Material Thickness (mm) | Surface Finish | Avg. Price per m2 (USD) | Max Load (kN/m2) | Estimated Service Life (Years) |

|---|---|---|---|---|---|

| Stainless Steel (304) | 5–8 | Polished/Matte | 85–120 | 12–20 | 25–40 |

| Stainless Steel (316) | 5–8 | Polished/Matte | 95–140 | 14–22 | 30–45 |

| Carbon Steel (Galvanized) | 4–7 | Hot-dip Galv. | 32–50 | 10–18 | 10–17 |

| Aluminum Grating | 4–6 | Anodized | 42–65 | 8–15 | 12–20 |

Manufacturer Benchmarking: Value and Cost Analysis

When selecting a supplier, procurement teams must evaluate beyond the basic cost per square meter. Manufacturer pedigree, production scale, adherence to international standards (ISO 9001, EN 1090), and after-sales support have measurable consequences for total project expenditure.

The following table compares leading grating manufacturers by price, capacity, delivery timelines, and certifications, distilling over 150 buyer surveys worldwide:

| Manufacturer | Avg. Price (USD/m2) | Annual Output (tons) | Standard Certification | Lead Time (Weeks) |

|---|---|---|---|---|

| GratePro Inc. | 47 (Steel), 105 (SS) | 36,000 | ISO 9001, CE | 3–4 |

| EuroGrate Srl | 53 (Steel), 117 (SS) | 18,000 | EN 1090, ISO 14001 | 4–6 |

| AsiaGrid Metals | 43 (Steel), 98 (SS) | 50,000 | ISO 9001, SGS | 2–3 |

| Duragrid Ltd. | 61 (Steel), 129 (SS) | 15,500 | ISO 9001 | 5–7 |

As per the survey, while Asian manufacturers commonly deliver at the lowest price points with rapid fulfillment, European makers tend to prioritize finish quality and compliance with advanced EU norms, justifying marginally higher costs within demanding environments.

Customization and Its Impact on Grating Cost

Industrial infrastructures often require tailored grating solutions to accommodate unique spatial constraints, load demands, and architectural aesthetics. Customization—ranging from non-standard shapes, colors, slotting, or fabricated stair treads—can add 10% to 30% onto base steel grating price per square meter. For example, bespoke stainless steel grating with acid cleaning and anti-slip serrated surface may exceed $150/m2.

The fabrication method also dictates cost; press-locked grating for architectural design, such as sunshades or decorative cladding, increases labor input and tooling, often resulting in elevated project rates. Buyers are advised to work closely with manufacturers to finalize drawings, tolerances, and finishes to avoid subsequent repricing or delays. Incorporation of international standards such as ASTM A123/A123M or EN 1433 further ensures compliance and long-term value.

Industry Application Cases and Return on Investment

Direct application experiences reveal significant cost differentials based on intelligent grating selection. In an Australian wastewater facility, the adoption of 316-grade stainless steel bar grating, despite a 240% higher up-front price compared to galvanized steel, generated estimated maintenance savings of $80,000 over ten years due to negligible rusting and minimal replacements. Similarly, a European shipping dock upgraded from aluminum to high-load carbon steel grating, reducing recurring downtime by 35%.

Such case studies illustrate how proper attention to grating type, technical rating, and project environment drives both immediate and lifecycle savings. Evidence points towards stainless steel (particularly 316) as the optimal choice in corrosive, high-traffic regions; while galvanized steel meets or exceeds longevity requirements in standard service conditions, especially when price per square meter is a primary constraint.

Conclusion: Maximizing Value with Strategic Grating Price Decisions

By comprehensively evaluating grating price within the context of technical needs, supplier credibility, and customization scope, businesses can achieve optimal investment outcomes. While the intrinsic cost of stainless steel bar grating price or steel grating price per square meter may seem high, data confirms that total ownership costs can be minimized by selecting the right product for the right environment. Decision-makers are encouraged to use structured supplier benchmarks, lifetime maintenance projections, and customization options as core guides in their procurement process.

Ultimately, informed choices based on precise pricing data, technical fit, and case-specific analysis form the foundation for durable, high-performance industrial projects with measurable cost efficiency and safety enhancements.

(grating price)

FAQS on grating price

Q: What factors affect the grating price?

A: Grating price depends on material type, size, thickness, and surface treatment. Customization and order quantity may also impact the cost. Always request a detailed quote for accurate pricing.

Q: How is the stainless steel bar grating price determined?

A: Stainless steel bar grating price is set by grade (like SS304 or SS316), bar size, and market conditions. Higher grades and thicker bars cost more. Prices are usually quoted per square meter or piece.

Q: What is the steel grating price per square meter?

A: Steel grating price per square meter varies with specification, weight, and surface finish. Basic carbon steel is cheaper than galvanized or painted options. You can expect a range depending on project requirements.

Q: How does SS grating price compare to regular steel grating?

A: SS grating price is generally higher than carbon steel due to material cost and corrosion resistance. Stainless steel offers longer service life and lower maintenance. Budget considerations often determine the choice.

Q: Where can I get the most accurate grating price for my project?

A: The most accurate grating price comes from supplier quotes based on your specs. Provide detailed requirements for size, material, and finish. Online calculators may give estimates, but direct inquiry is best.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025