- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 13, 2025 12:38

Back to list

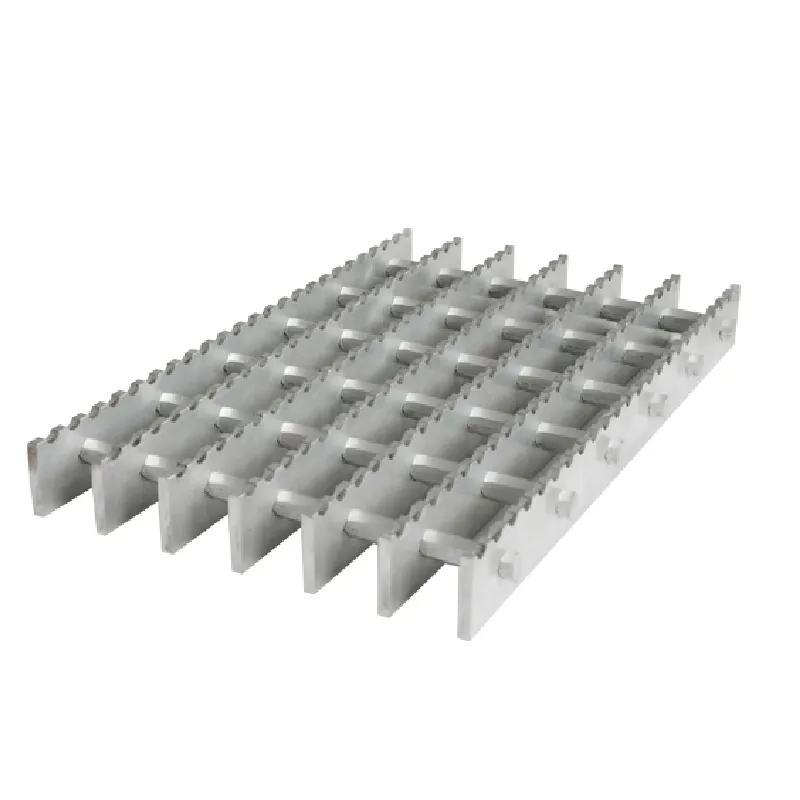

floor steel grating

Navigating the world of flooring solutions, particularly floor grating, requires a keen understanding not only of the options available but also of the pricing dynamics that govern this essential component. Floor grating, often employed in industrial environments, walkways, and various architectural applications, offers robust strength and durability. Yet, the price of floor grating can vary widely depending on several critical factors. Here we delve into the nuanced aspects that influence floor grating pricing and how businesses and individuals can make informed decisions.

Market demand and supply chain dynamics cannot be ignored in the pricing equation. Economic fluctuations, the availability of raw materials, and global supply chain disruptions can cause prices to shift unexpectedly. Staying informed about market trends and working with reputable suppliers with transparent pricing can mitigate unforeseen costs and provide a clearer picture of available options. Installation processes and labor costs might not directly affect the grating price but contribute significantly to overall project expenses. Different types of grating might require specialized installation procedures, impacting labor costs. Clients should factor in these expenses when budgeting for their flooring projects, ensuring that installation complexities do not eclipse the initial savings on material costs. Sourcing floor grating from authorized and well-established suppliers enhances trustworthiness and ensures quality. Suppliers with extensive industry experience provide products that meet safety and regulatory standards, offering long-term reliability and performance. Detailed attention to these criteria not only supports an informed buying decision but also strengthens the foundation for a successful flooring project, balancing cost, functionality, and durability in perfect harmony.

Market demand and supply chain dynamics cannot be ignored in the pricing equation. Economic fluctuations, the availability of raw materials, and global supply chain disruptions can cause prices to shift unexpectedly. Staying informed about market trends and working with reputable suppliers with transparent pricing can mitigate unforeseen costs and provide a clearer picture of available options. Installation processes and labor costs might not directly affect the grating price but contribute significantly to overall project expenses. Different types of grating might require specialized installation procedures, impacting labor costs. Clients should factor in these expenses when budgeting for their flooring projects, ensuring that installation complexities do not eclipse the initial savings on material costs. Sourcing floor grating from authorized and well-established suppliers enhances trustworthiness and ensures quality. Suppliers with extensive industry experience provide products that meet safety and regulatory standards, offering long-term reliability and performance. Detailed attention to these criteria not only supports an informed buying decision but also strengthens the foundation for a successful flooring project, balancing cost, functionality, and durability in perfect harmony.

Share

Next:

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025