- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 05, 2025 00:45

Back to list

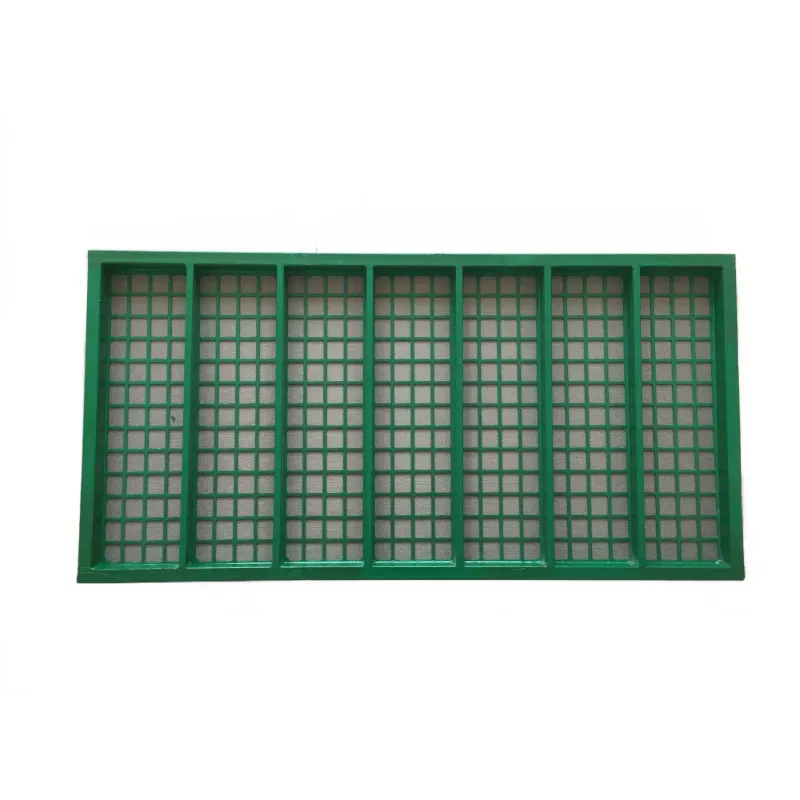

heavy duty steel grating

When considering the design and construction of heavy-duty platforms, walkways, or drainage covers, heavy duty steel grating emerges as a top contender due to its durability, versatility, and strength. Its robust design is meticulously crafted to withstand intense pressure, high-load capacities, and extreme environmental conditions, making it invaluable across various industries including energy, construction, and transportation.

Moreover, installation simplicity is one of the many reasons heavy duty steel grating continues to gain favor. Unlike other materials that require extensive downtime during installation, steel grating is relatively easy to install and requires minimal adjustments on-site. This expedited installation process reduces project costs and time while maintaining high safety standards. Sustainability is another dimension of heavy duty steel grating's expertise. As industries pivot towards more eco-friendly practices, steel, being one of the most recyclable materials, aligns with efforts to reduce environmental footprints. Its recyclability does not compromise its structural benefits, making it a sustainable choice for modern projects. From a maintenance perspective, the resilience of heavy duty steel grating cannot be overstated. Unlike materials that may require frequent replacement or repair, steel grating's resistance to impact, rust, and physical wear prolongs its service life, thereby ensuring reliable performance and safety over extended periods. The extensive use of heavy duty steel grating across different sectors is a testament to its performance and versatility. It seamlessly blends functionality, safety, and cost-effectiveness, offering a dependable solution for structures requiring robust support. Its indispensability in applications ranging from industrial floors, offshore platforms, to public infrastructure signifies a well-earned reputation as a material of choice among engineers and architects. When considering the broader implications of choosing heavy duty steel grating, it becomes clear that the emphasis should be placed on understanding specific project needs and the grating's adaptability to meet those requirements. Whether it's the need for increased load-bearing capacity or resistance to extreme environmental conditions, heavy duty steel grating stands as a reliable solution reaffirmed by decades of steadfast service across myriad applications.

Moreover, installation simplicity is one of the many reasons heavy duty steel grating continues to gain favor. Unlike other materials that require extensive downtime during installation, steel grating is relatively easy to install and requires minimal adjustments on-site. This expedited installation process reduces project costs and time while maintaining high safety standards. Sustainability is another dimension of heavy duty steel grating's expertise. As industries pivot towards more eco-friendly practices, steel, being one of the most recyclable materials, aligns with efforts to reduce environmental footprints. Its recyclability does not compromise its structural benefits, making it a sustainable choice for modern projects. From a maintenance perspective, the resilience of heavy duty steel grating cannot be overstated. Unlike materials that may require frequent replacement or repair, steel grating's resistance to impact, rust, and physical wear prolongs its service life, thereby ensuring reliable performance and safety over extended periods. The extensive use of heavy duty steel grating across different sectors is a testament to its performance and versatility. It seamlessly blends functionality, safety, and cost-effectiveness, offering a dependable solution for structures requiring robust support. Its indispensability in applications ranging from industrial floors, offshore platforms, to public infrastructure signifies a well-earned reputation as a material of choice among engineers and architects. When considering the broader implications of choosing heavy duty steel grating, it becomes clear that the emphasis should be placed on understanding specific project needs and the grating's adaptability to meet those requirements. Whether it's the need for increased load-bearing capacity or resistance to extreme environmental conditions, heavy duty steel grating stands as a reliable solution reaffirmed by decades of steadfast service across myriad applications.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025