- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

steel bar grating load tables

Understanding Steel Bar Grating Load Tables

Steel bar grating is a popular choice in construction and industrial applications due to its strength, durability, and versatility. It provides a safe walking surface and efficient drainage, making it ideal for various applications, from flooring to walkways, platforms, and even in the framework of industrial equipment. One of the key aspects of selecting and installing steel bar grating is understanding the load tables associated with it.

Load tables for steel bar grating outline the load-carrying capacity of different types of grating based on their design, material, and dimensions. These tables help engineers, architects, and designers determine the appropriate grating for specific applications, ensuring safety and efficiency. The tables typically include parameters such as span, load ratings, and deflection limits.

Key Factors in Load Tables

1. Span This refers to the distance between two supports that the grating will rest on. The span significantly affects the load capacity; as the span increases, the weight that the grating can support may decrease. It is crucial to consult the load tables to find the correct span-to-load ratio for the specific type of grating being used.

2. Load Ratings Load ratings are typically presented in terms of uniform load (typically measured in pounds per square foot or PSF), concentrated load (typically measured in pounds), and the type of loading (static or dynamic). Understanding these ratings is essential for determining if a particular grating can safely handle the expected loads in a given application.

3. Deflection Limits Deflection is the degree to which a structural element bends under load. Load tables will often specify maximum allowable deflection, which is crucial for ensuring that the grating not only supports the necessary load but also maintains structural integrity and user comfort. Common deflection limits are set to sustain safety and to avoid potential hazards.

steel bar grating load tables

Types of Steel Bar Grating

There are several types of steel bar grating, with the most common being welded, press-locked, and swage-locked. Each type has different attributes and load capacities, depending on its design and the spacing of the bearing bars. Understanding the specific type of grating being used is imperative when consulting load tables, as the load-bearing capabilities can vary widely between them.

Applications and Considerations

When selecting steel bar grating, it is essential to consider the specific application areas, such as pedestrian traffic, vehicular traffic, or heavy machinery support. Different environments will place varying loads on the grating, necessitating a thorough review of the load tables to find an adequate match. Additionally, factors like corrosion resistance, chemical exposures, and thermal conditions should be evaluated to ensure long-term performance.

Conclusion

In conclusion, load tables for steel bar grating are crucial tools for ensuring safety and functionality in various applications. By understanding the interplay between span, load ratings, and deflection limits, professionals can make informed decisions that ensure the longevity and effectiveness of their installations. Always refer to the relevant standards and manufacturer specifications when working with steel bar grating to uphold safety and reliability principles in construction and industry.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

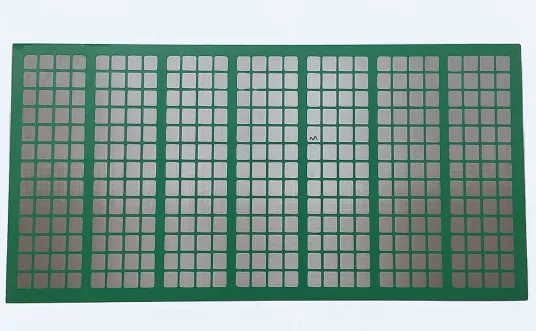

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025