- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Creating a Similar 1% 201% 4 Bar Grating Design Proposal for Optical Applications

Understanding 1% 201% 4% Bar Grating A Comprehensive Overview

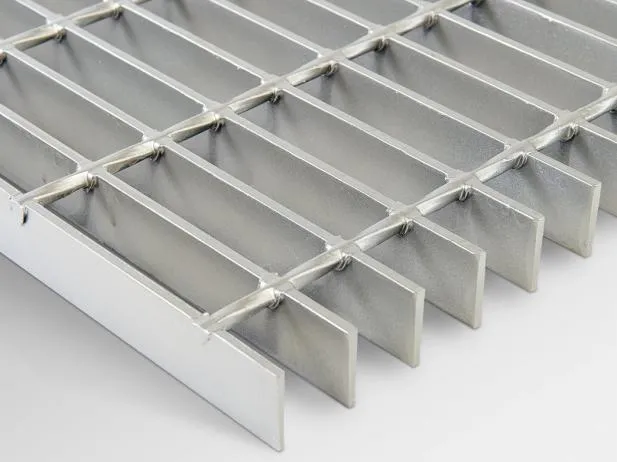

Bar grating, a versatile and durable material, is widely used across various industries, particularly in construction and architecture. Specifically, when we refer to 1% 201% 4% bar grating, we are often highlighting its distinct properties and applications that set it apart from other materials. In this article, we will delve into what this terminology means and explore its implications in real-world applications.

At its core, bar grating consists of a series of parallel, longitudinal bars, held together by cross bars at specific intervals. The 1% 201% 4% may denote specific design attributes or standards that cater to particular requirements, such as load-bearing capacity and spacing configuration. Understanding these percentages is vital for engineers and architects who must ensure that their projects meet safety standards and functional demands.

Characteristics of Bar Grating

Bar grating can be fabricated from various materials, including steel, aluminum, and fiberglass, each offering unique benefits. Steel grating, for instance, is particularly known for its strength and durability, making it ideal for heavy-duty applications. In comparison, aluminum grating is lighter and resistant to corrosion, suitable for environments exposed to moisture and chemicals.

The configuration of bar grating also plays a crucial role in its performance. 1% 201% 4% may refer to the spacing between bars and the thickness of the material used. These ratios impact factors such as load distribution, airflow, and light penetration. Grating with closer spacing may offer better support but could restrict visibility or airflow, while wider spacing allows for greater light transmission and drainage.

Applications

1 1 4 bar grating

Bar grating is widely utilized in numerous applications. In the construction industry, it serves as flooring for walkways, platforms, and industrial areas. Its open design allows for efficient drainage, making it ideal for areas prone to moisture accumulation. Additionally, bar grating is frequently used in stair treads, providing safety and traction for pedestrians.

In wastewater treatment plants, bar grating is used for cover systems, ensuring safety while allowing for the passage of air and light. Its corrosion-resistant variants are particularly valuable in such settings, where exposure to harsh chemicals is common. In the energy sector, bar grating can be found in power plants, providing walkways and platforms for maintenance and operations.

Benefits and Future Trends

One of the significant advantages of bar grating is its ability to be customized to meet specific project requirements. Advances in manufacturing technology enable the production of grating with precise dimensions and specifications, such as those indicated by “1% 201% 4%.” This customizability ensures that engineers can achieve optimal safety and functionality.

Looking ahead, the future of bar grating will likely involve enhanced materials and designs. With an increasing focus on sustainability, we may see a rise in the use of recycled materials in bar grating manufacturing. Furthermore, innovations in anti-slip coatings and corrosion-resistant treatments will likely improve the performance and longevity of bar grating, making it an even more attractive option for various applications.

In conclusion, understanding the nuances of 1% 201% 4% bar grating allows professionals in construction and engineering to make informed decisions that align with safety and efficiency standards. Its diverse applications and adaptability make bar grating a crucial component in modern infrastructure.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025